New energy automobile part spraying equipment

A technology of new energy vehicles and spraying equipment, applied in spray booths, spraying devices, etc., can solve the problems of incomplete spraying and low spraying efficiency, and achieve the effect of ensuring the quality of spraying paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

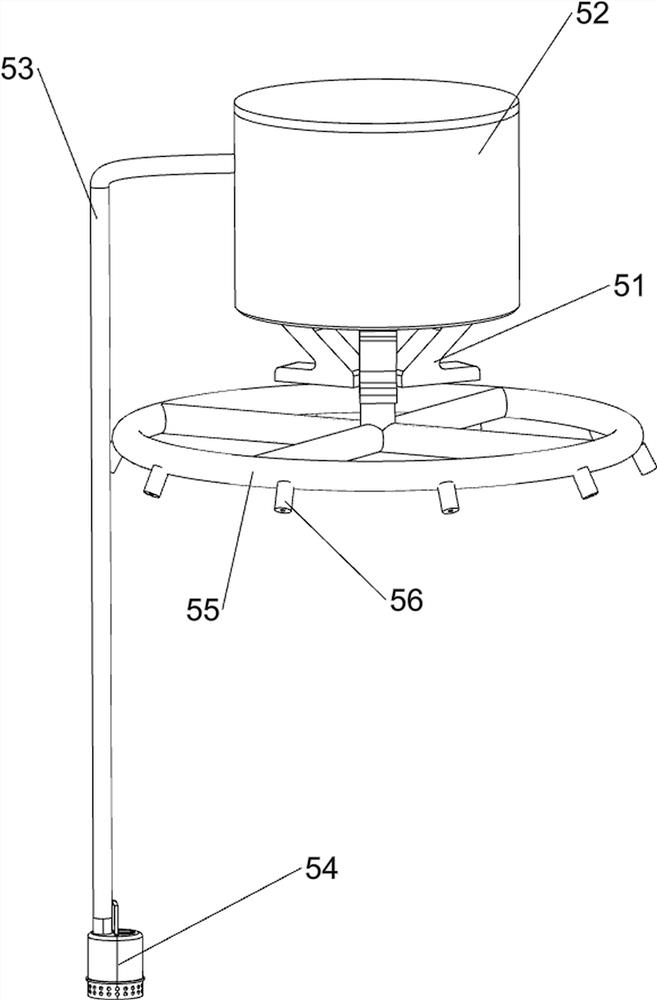

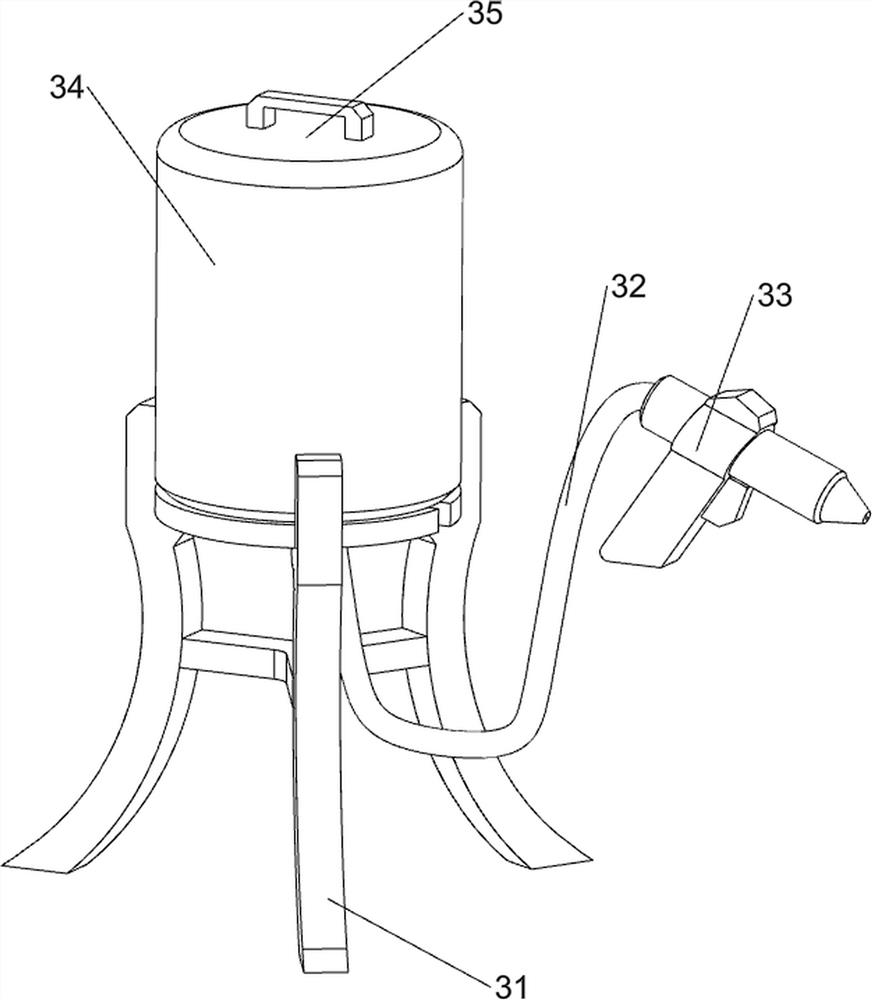

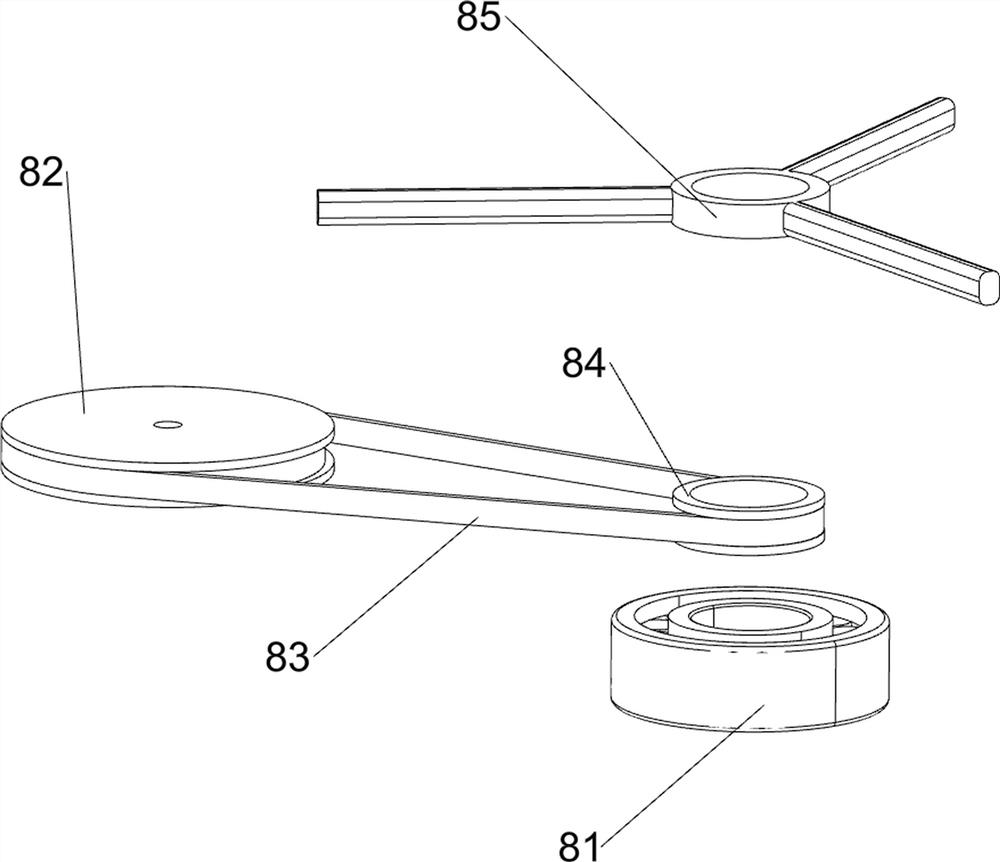

[0025] A new energy vehicle parts spraying equipment, such as Figure 1-7 As shown, it includes a support base plate 1, a foot 2, a spraying mechanism 3 and a placement mechanism 4, a plurality of support feet 2 are provided at the bottom of the support base plate 1, a spraying mechanism 3 is provided on the left side of the top support base plate 1, and a spraying mechanism 3 is provided on the left side of the support base plate 1 top. There are placement mechanisms4.

[0026] The worker injects the paint into the spraying mechanism 3, then fixes the wheel hub in the placing mechanism 4, starts the spraying mechanism 3 to work, and sprays the wheel hub. Carry out overall painting, after painting is finished, close spraying mechanism 3, wheel hub is taken off from placement mechanism 4 and gets final product.

[0027] The spraying mechanism 3 includes a storage bucket tripod 31, a hose 32, a spray gun 33, a paint storage bucket 34 and a bung 35, and the left side of the supp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap