Extruder nozzle assembly based on melt-blown cloth preparation

A nozzle assembly and extruder technology, which is applied to the spinneret assembly, feeding solution to the spinneret, non-woven fabric, etc., can solve the problems of difficult spray angle adjustment, waste, and use limitations, etc. The effect of adapting to the effect and ensuring the effect of circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

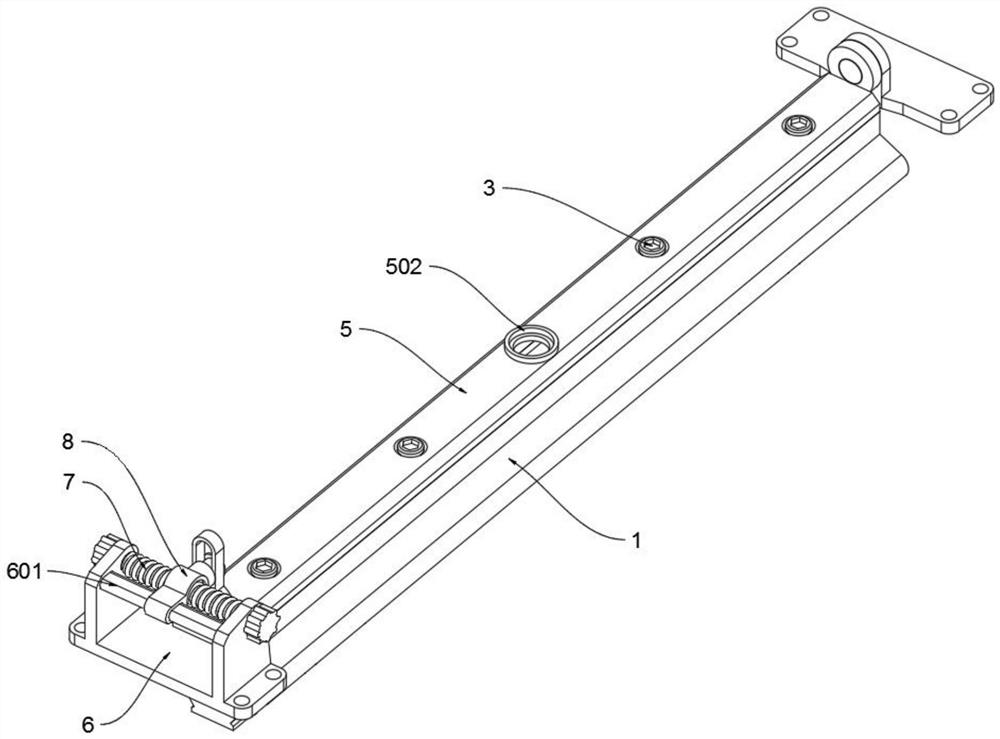

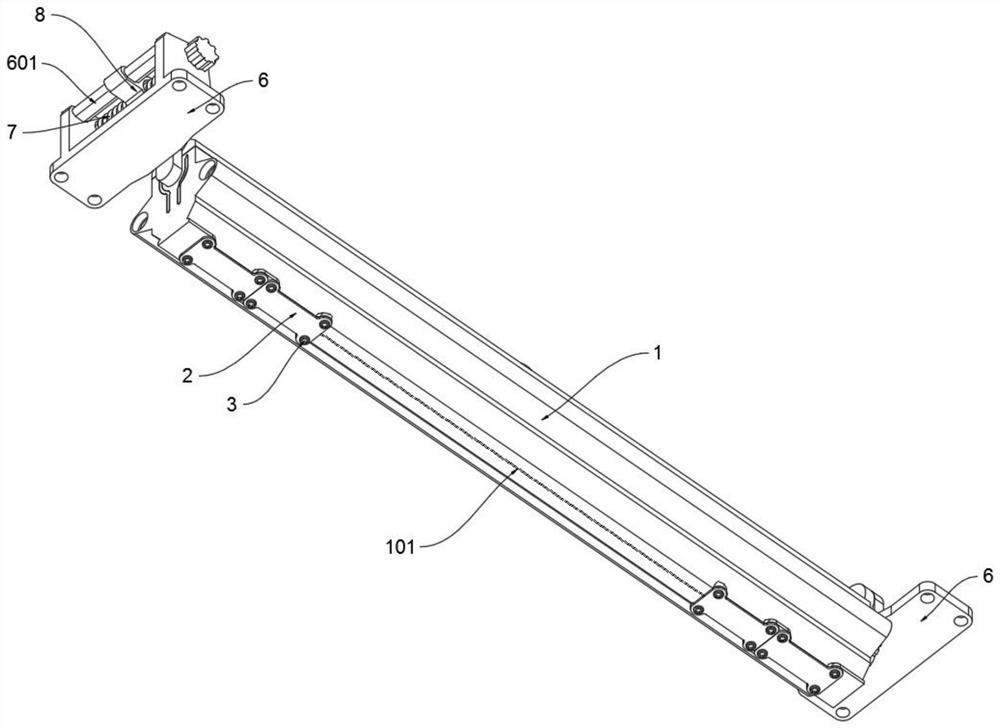

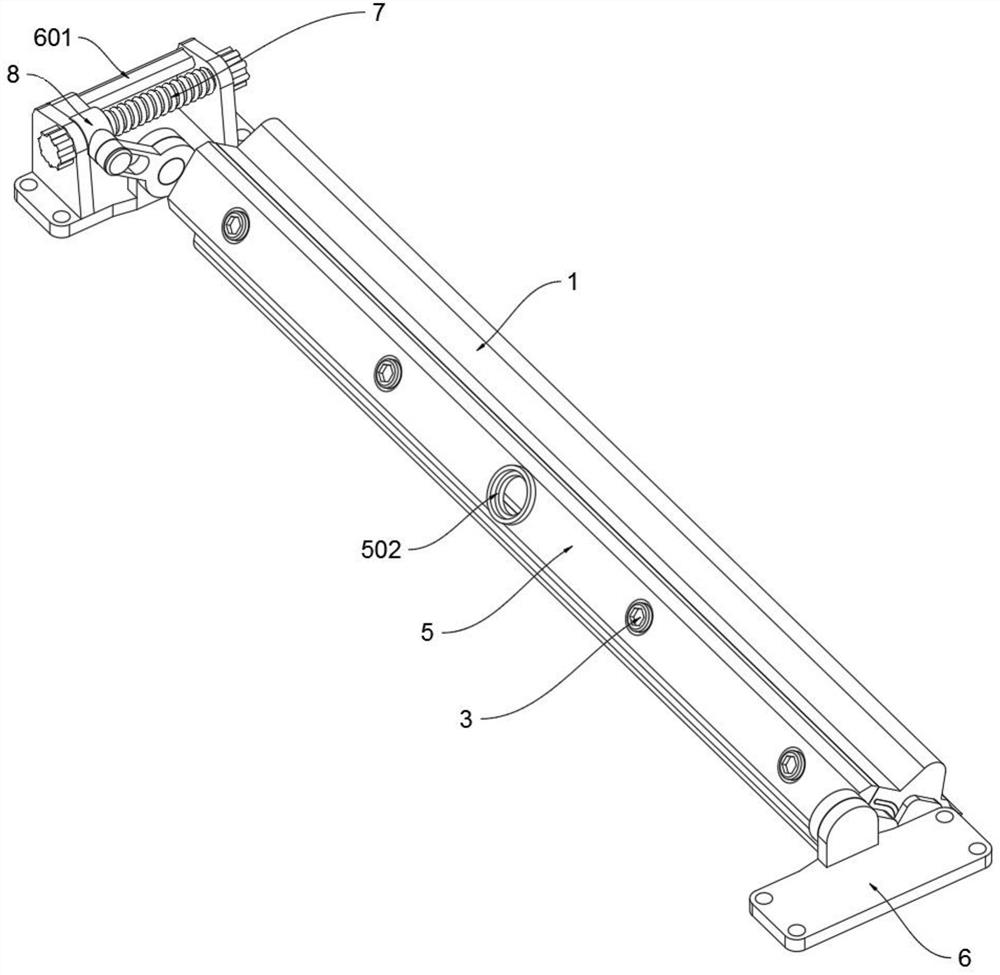

[0032] as attached figure 1 to attach Figure 9 Shown:

[0033] The present invention provides an extruder nozzle assembly prepared based on melt-blown cloth, including a nozzle 1, a sealing bottom plate 2, a sealing top cover 5, a base 6 and a screw 7; There are multiple feeding sub-holes 103, and the left end of the nozzle 1 is symmetrically provided with two hot gas inlets 104; the left and right ends of the nozzle 1 are respectively provided with a rotating hole 106, and the rotating holes 106 at the left and right ends of the nozzle 1 are respectively connected to two The base 6 is rotated and connected, and the nozzle 1 can be rotated and adjusted according to the requirements for the preparation of the melt-blown cloth, and the angle of the microhole 101 on the bottom side of the nozzle 1 can be changed to ensure the adaptability of the nozzle 1; there are four sealing bases 2, and the sealing base 2 is located at The bottom side of the nozzle 1; the top of the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com