Variable-liquid-level periodic uniform-flow water outlet device

A liquid level and water outlet technology, which is applied to water supply devices, waterway systems, drainage structures, etc., can solve problems such as inapplicability, large changes in water outlet flow, and reduced discharge flow, so as to reduce power costs and maintenance costs. Anticipated impact, dynamics provide a steady effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

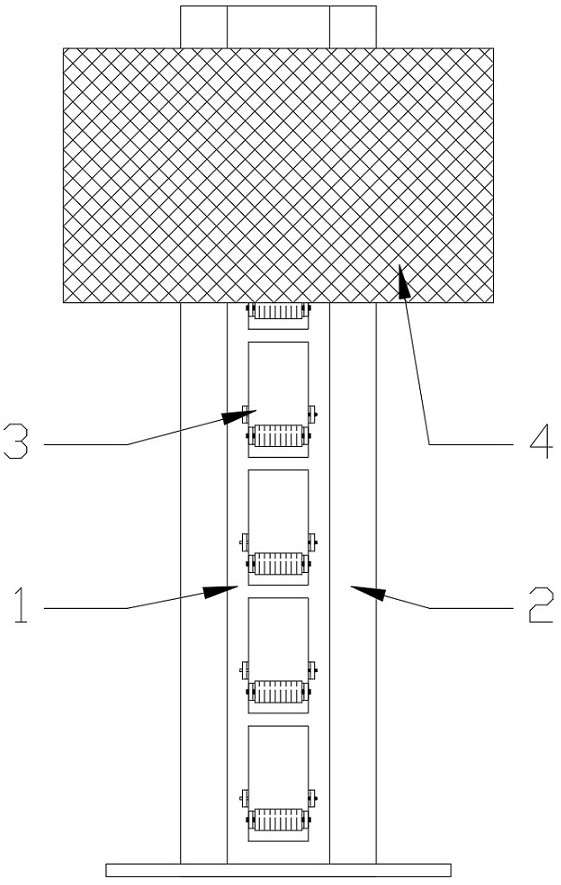

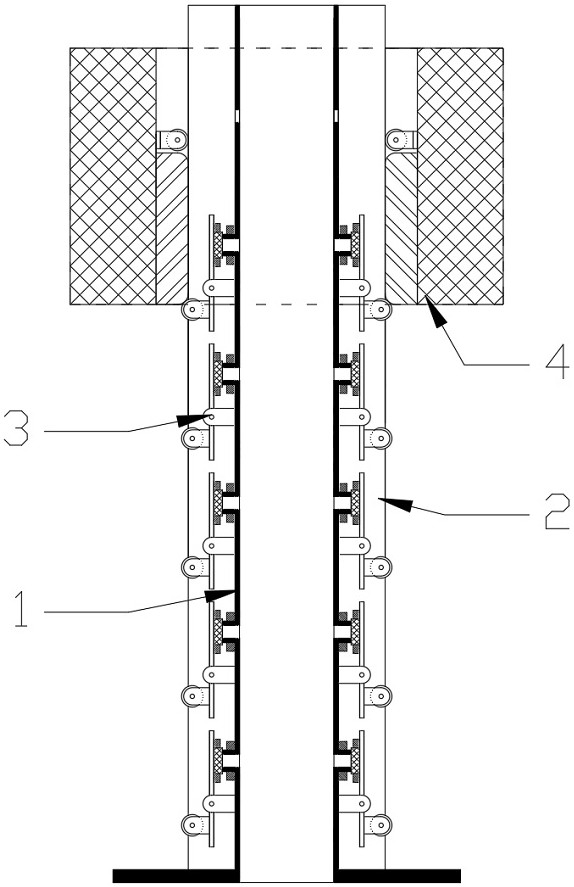

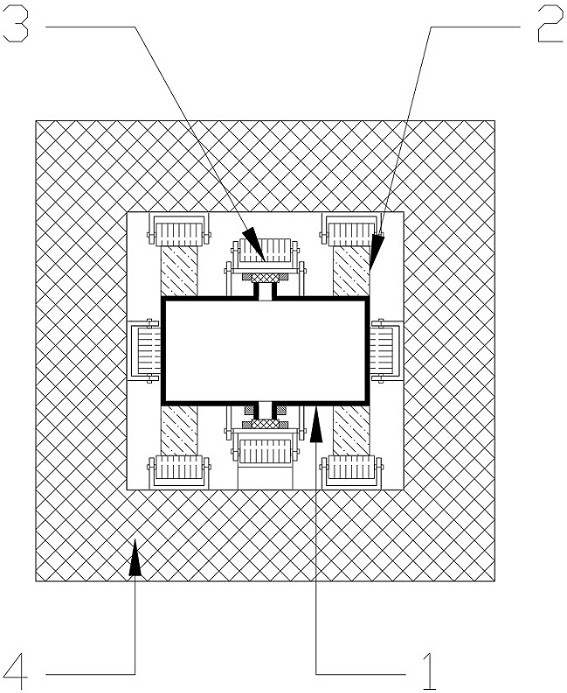

[0036] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0037] Such as Figure 1-12 Shown is a variable liquid level periodic water outlet device provided by the present invention, including an outlet pipe 1, a guide rail 2, a magnetic valve 3 and a floating body trigger cylinder 4; its feature is that the outlet pipe 1 is installed vertically on Inside the water tank, the bottom end of the outlet pipe 1 communicates with the water outlet of the water tank, the guide rail 2 is installed on the radially outer side of the outlet pipe 1, and the magnetic valve 3 is provided with multiple valves installed on two opposite sides of the outlet pipe 1. and arranged equidistantly from top to bottom; the floating body trigg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com