Buffering structure of earthquake-avoiding safety cabin

A buffer structure and safety technology, which is applied in the direction of earthquake resistance, building components, special buildings, etc., can solve the problems of insufficient safety performance of the shock-absorbing safety cabin, poor buffering effect, and too simple buffering mechanism, so as to reduce strong vibration and reduce Vibration, the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

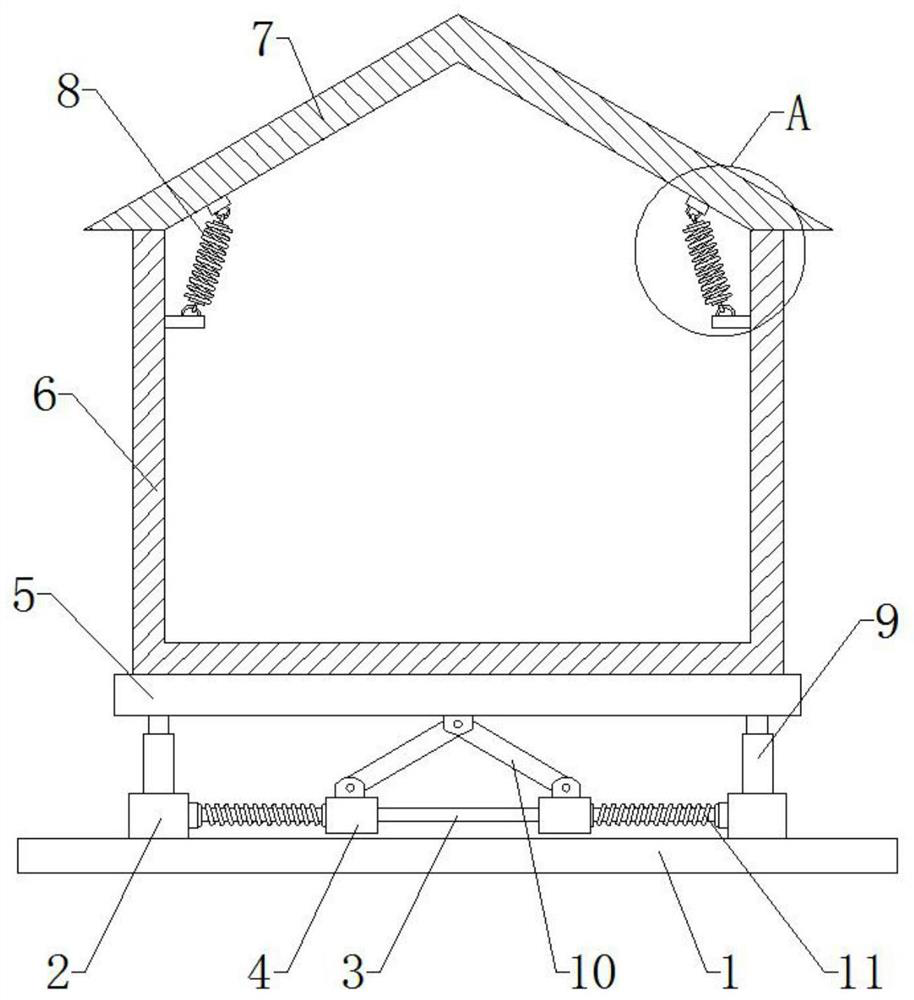

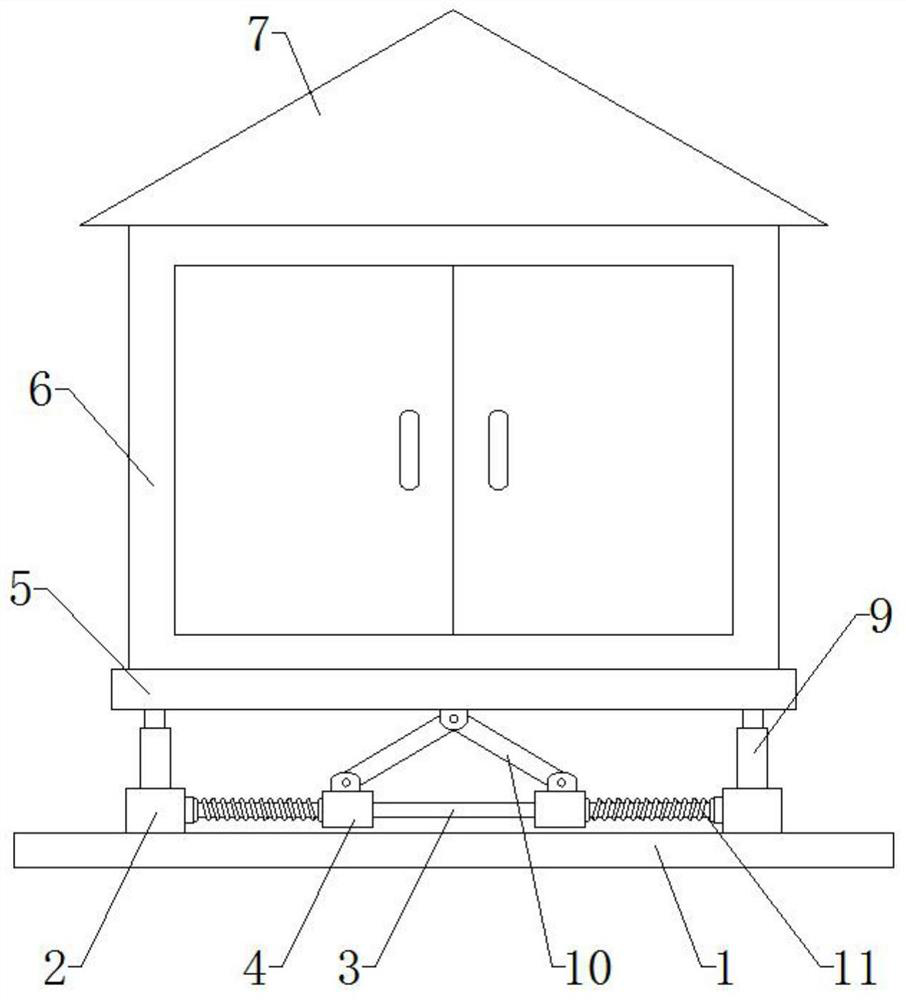

[0026] Embodiment 1: When the top plate 5 vibrates up and down, it drives the rotating rod 10 to rotate, and the rotating rod 10 drives the sliding sleeve 4 to slide slightly. The telescopic spring 11 can provide a certain elastic force and buffer force, which ensures sufficient buffering for the mounting plate 8 force.

Embodiment 2

[0027] Embodiment 2: Gas springs 9 are fixedly connected to the fixing seats 2 , the top plate 5 is located above the bottom plate 1 , and the bottom of the top plate 5 is fixedly connected to the top of the gas spring 9 . The gas spring 4 also plays a certain damping effect, thereby effectively reducing the strong vibration of the safety chamber 6.

Embodiment 3

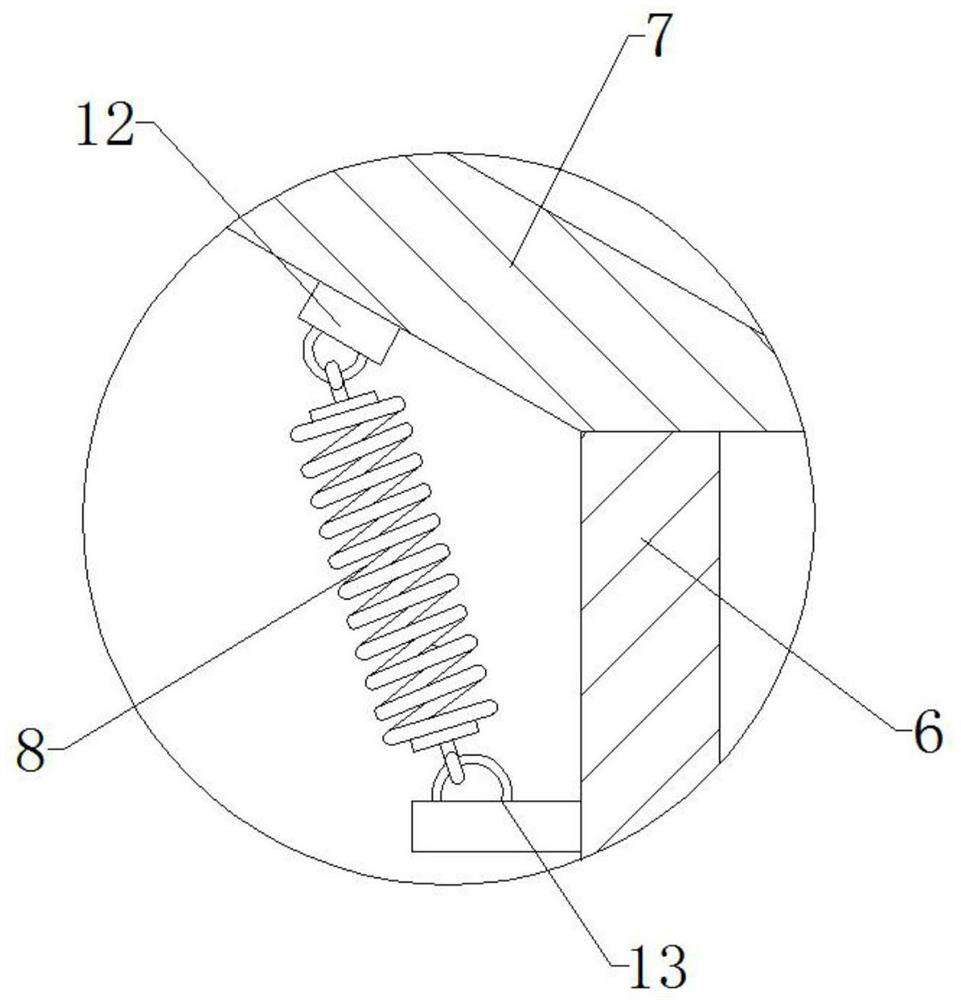

[0028] Embodiment three: the first spring seat 12 is provided on the inner walls of both sides of the roof 7, and the second spring seat 13 is provided above the inner walls of the two sides of the safety chamber 6, and the first spring seat 12 and the second spring seat 13 All have clasps. Both sides of the top in the safety chamber 6 are provided with damping springs 8, and the two ends of the damping springs 8 are provided with hooks, and the hooks match the clasps. The damping spring 8 can effectively relieve the resonance between the safety chamber 6 and the roof 7, and improves the safety of the safety chamber 6 body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com