Multi-mode tunnel boring machine (TBM) earth pressure monitoring system and working method thereof

A monitoring system and roadheader technology, which is applied in earthwork drilling, mining equipment, tunnels, etc., can solve the problems of sensors affecting production progress, and achieve the effect of reducing downtime costs and improving production progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

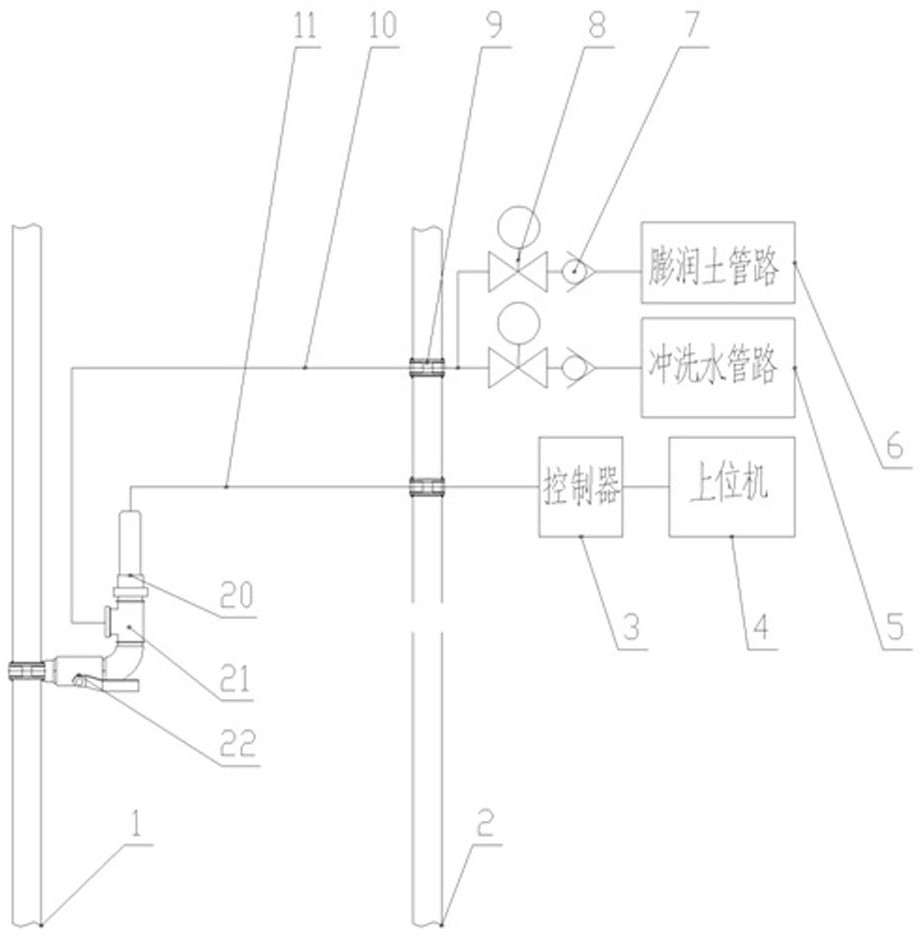

[0023] Embodiment 1: as figure 1 As shown, a multi-mode roadheader earth pressure monitoring system includes a front bulkhead 1 and a rear bulkhead 2. At least one set of first control valves 22 are installed on the front bulkhead 1, and the first control valves are manual ball valves. The manual ball valve can be controlled manually or remotely through the controller. A relay joint 21 is installed on the upper part of the first control valve 22. A pressure sensor 20 is installed on the upper part of the relay joint 21. The relay joint 21 passes through the medium injection channel 10 respectively. It is connected with the bentonite pipeline 6 and the flushing water pipeline 5. The upper and lower ports of the relay joint are respectively connected to the first control valve and used to install the pressure sensor. The other port of the relay joint injects water / bentonite into the sensor through the medium injection channel. 20 end, and can be injected into the excavation bin ...

Embodiment 2

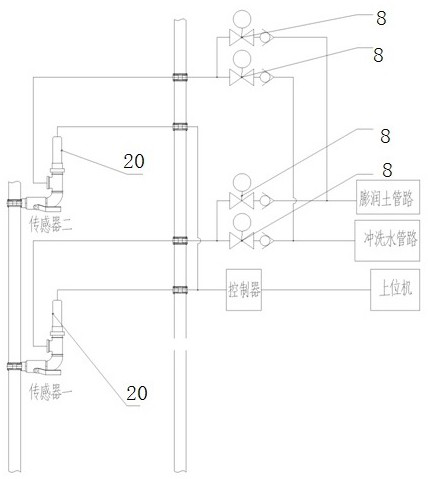

[0026] Embodiment 2: multi-mode roadheader earth pressure monitoring system, the actual configuration number of control valves can be appropriately increased according to the number of sensors required by different models, the number of settings for the first control valve 22 is two groups, the first two groups The relay joint 21 on the control valve 22 is respectively connected with the bentonite pipeline 6 and the flushing water pipeline 5 through the medium injection channel 10 arranged in parallel. The relay joint on the valve injects the medium through the medium injection channel, thereby realizing the multi-mode injection pipeline of the dual-channel roadheader and improving the accuracy of the earth pressure monitoring parameters.

Embodiment 3

[0027] Embodiment 3: A working method of a multi-mode roadheader earth pressure monitoring system, comprising the following steps:

[0028] S1. Install the first control valve 22 on the front bulkhead 1, install the relay joint 21 between the first control valve 22 and the pressure sensor 20, and use the pressure sensor 20 to monitor the earth pressure of the roadheader in real-time in the earth pressure mode. The sensor The connecting wire is connected to the controller 3 through the sensor wiring channel 11 through the bulkhead joint 9 of the rear bulkhead 2, and the other interface of the relay joint 21 injects flushing water or bentonite into the end of the pressure sensor 20 through the medium injection channel 10, And through the first control valve 22 through the front partition 1 into the excavation chamber;

[0029] S2. Earth pressure mode: the controller controls the on-off valve 8 connected to the bentonite pipeline to open at regular intervals, and through the pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com