Broken shaft repairing method

A repair method and broken shaft technology, which is applied in the field of equipment repair, can solve problems such as equipment downtime, load-bearing torsional shear force difference, and influence on normal production, and achieve the effects of reducing downtime costs, increasing service life, and reducing repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

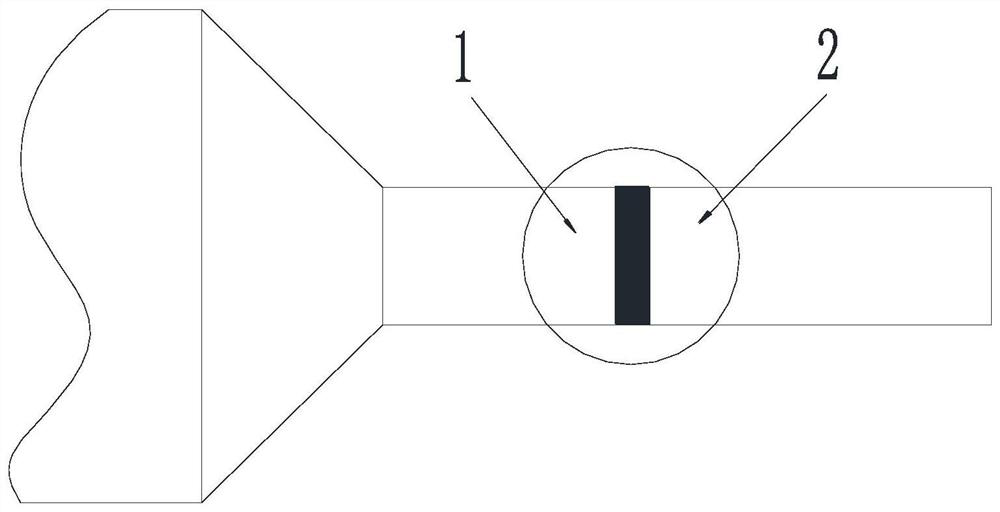

[0043] A broken shaft repair method, comprising:

[0044] Steps for preparing materials: Use the repair section with the same material and heat treatment method as the broken shaft section; the broken shaft section is made of 45# steel, and the quenched and tempered hardness is HB215-240, then the material of the repair section is also 45# steel. The hardness is HB215-240.

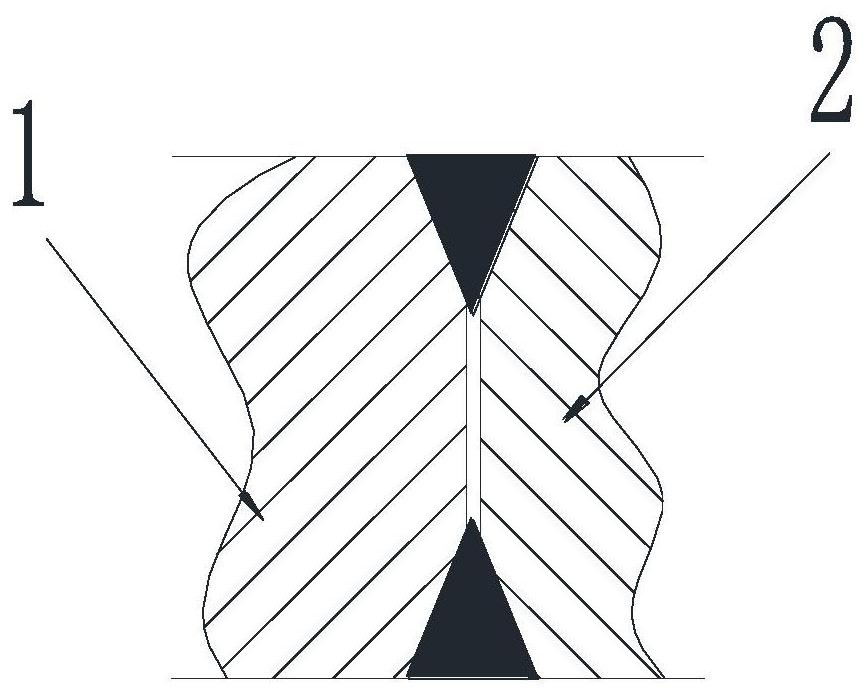

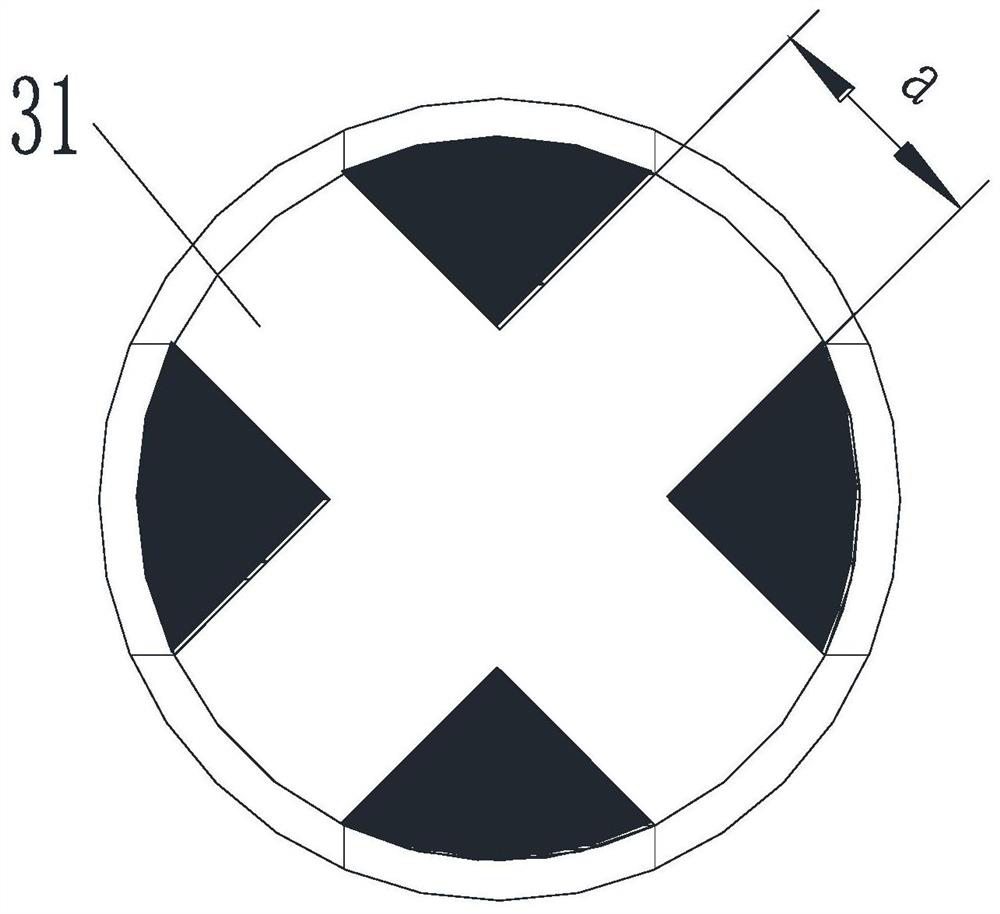

[0045] Milling steps: mill a cross groove on the end face of the broken shaft section, the groove runs through the end face of the broken shaft section, that is, the groove runs through the end face in the length direction, and a convex part is milled on the end face of the repaired section. grooves to match;

[0046] Among them, the diameter of the broken shaft section to be repaired is 100mm, the size of the groove is: the width of the groove is a=23mm, and the bring-in tolerance is The groove depth h = 25mm, and the bring-in tolerance is Then the corresponding convex part size: convex part width a1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com