Honeycomb type anti-explosion tank

An explosion-proof tank and honeycomb-type technology, applied in blasting and other directions, can solve problems such as insufficient structural design and functions of explosion-proof tanks, unsatisfactory use needs, and hidden safety hazards, etc., to achieve convenient production and use methods, simple and practical overall structure, The effect of improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

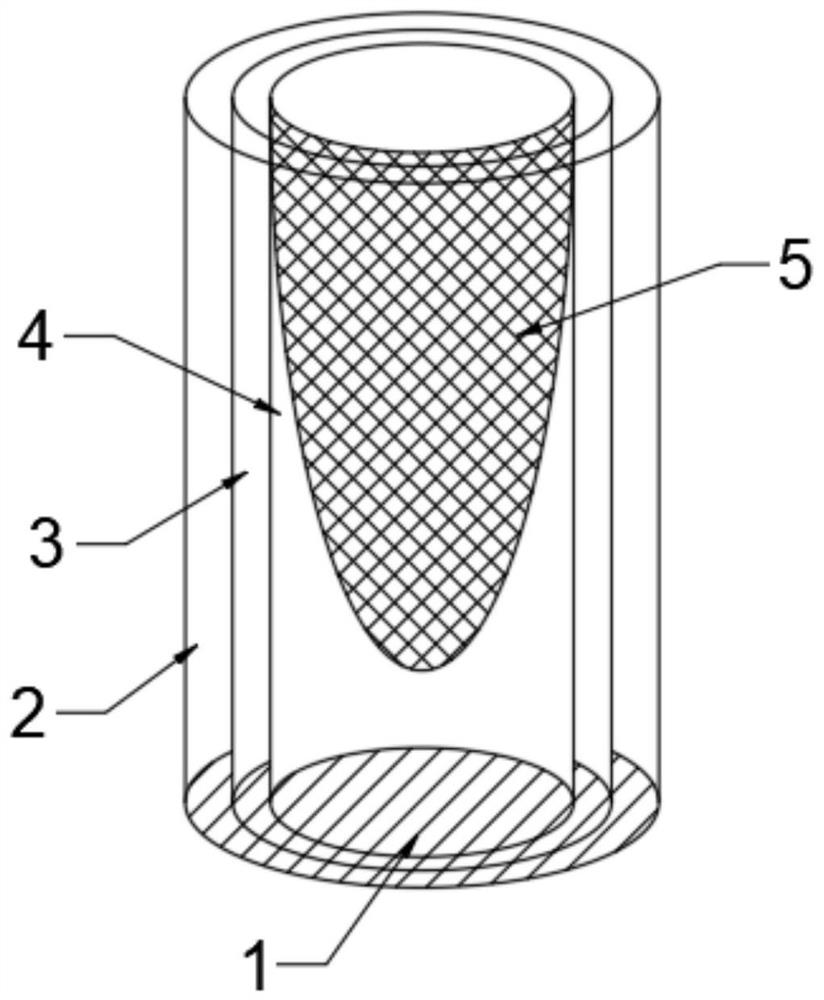

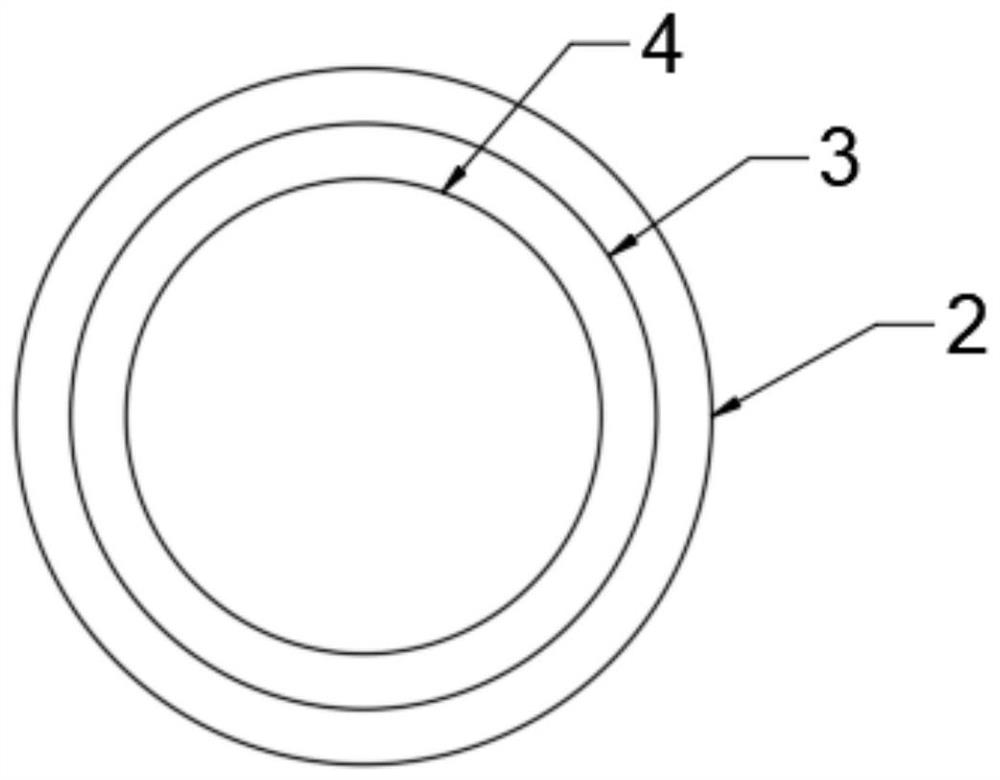

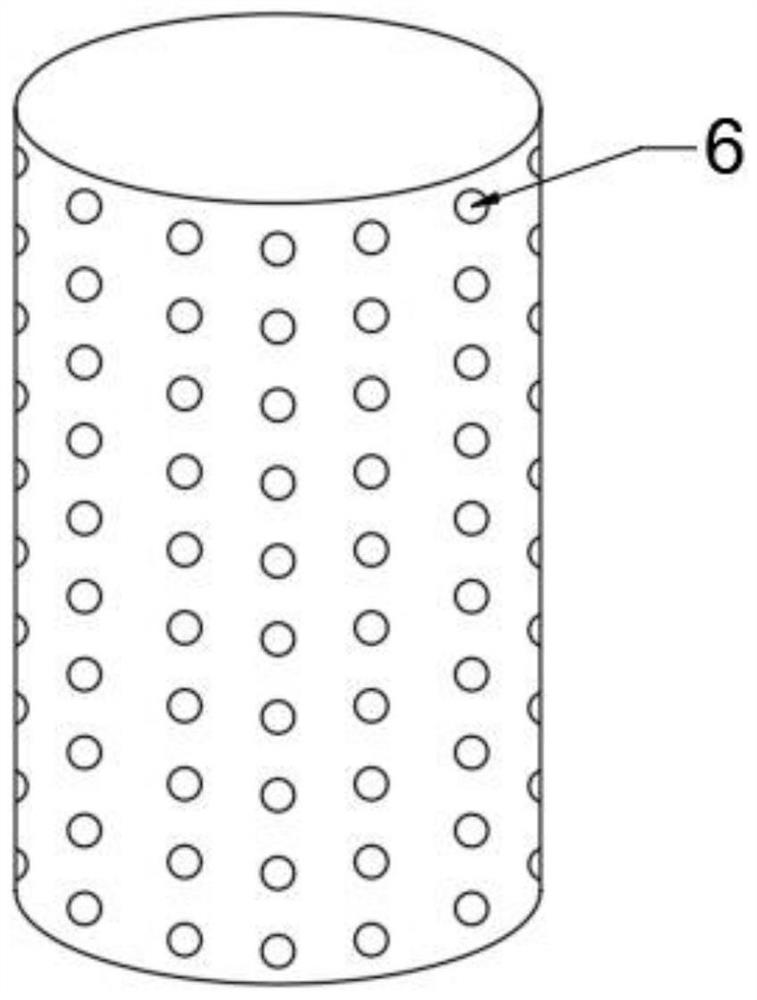

[0015] When the present invention is specifically implemented, a honeycomb explosion-proof tank includes a base plate 1, a cylindrical barrel wall 2, a cylindrical barrel wall 2 3, a cylindrical barrel wall 3 4, a net bag 5, and a through hole 6. The bottom plate 1 It is a circular bulletproof steel plate with a diameter of 1.4m and a thickness of 1cm. The base plate 1 is welded with a cylindrical barrel wall 12, and a cylindrical barrel wall 2 is arranged inside the cylindrical barrel wall 2. The cylindrical barrel wall There is a cylindrical barrel wall 3 4 inside the second 3, and the cylindrical barrel wall 1 2, the cylindrical barrel wall 2 3 and the cylindrical barrel wall 2 3 are all welded on the bottom plate 1, and the top is an open design without a top cover. The cylindrical barrel wall 3 4 is provided with a net pocket 5, and the edge of the net p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com