Axial stress measuring device with novel electromagnetic ultrasonic longitudinal wave transducer

An electromagnetic ultrasonic and axial stress technology, applied in the direction of measuring device, measuring force, and using stable tension/pressure to test the strength of materials, etc. Good transmission effect, good measurement sensitivity, good contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

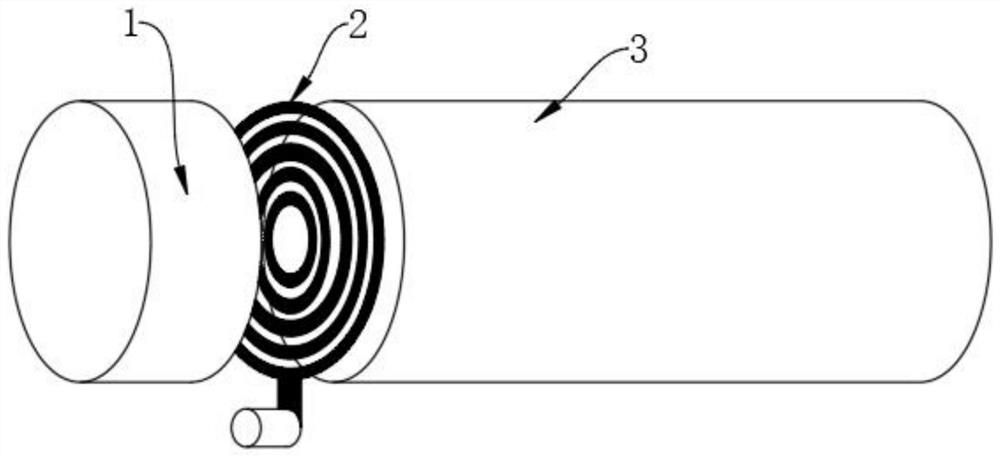

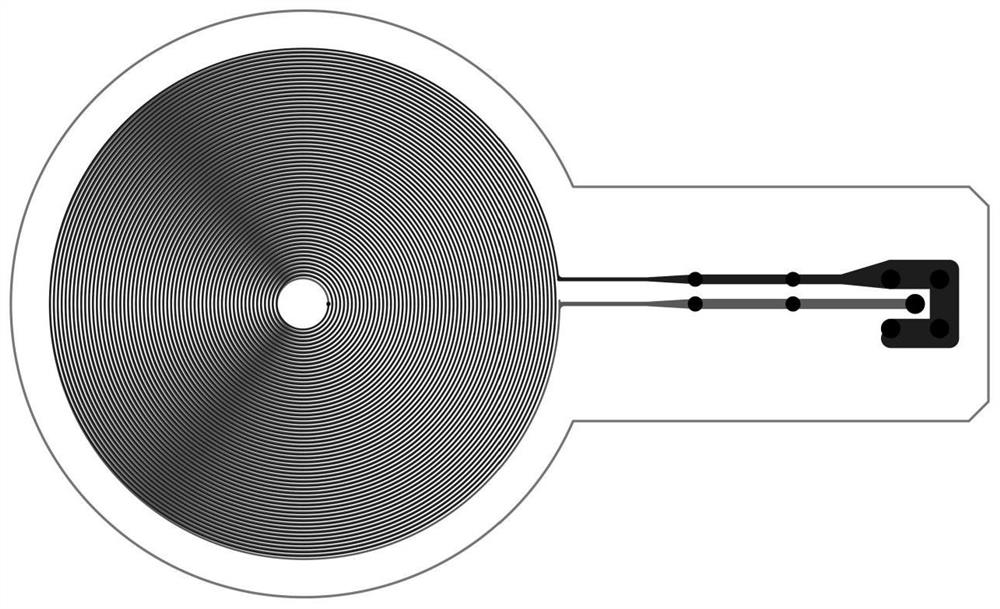

[0031] like Figure 1-3 As shown: the present invention includes a permanent magnet assembly 1, a helical coil 2 and an aluminum alloy rod 3, the lower end surface of the helical coil 2 is fixedly arranged in the middle of the upper end of the aluminum alloy rod 3, and the lower end of the permanent magnet assembly 1 is fixed It is arranged on the upper end surface of the spiral coil 2 .

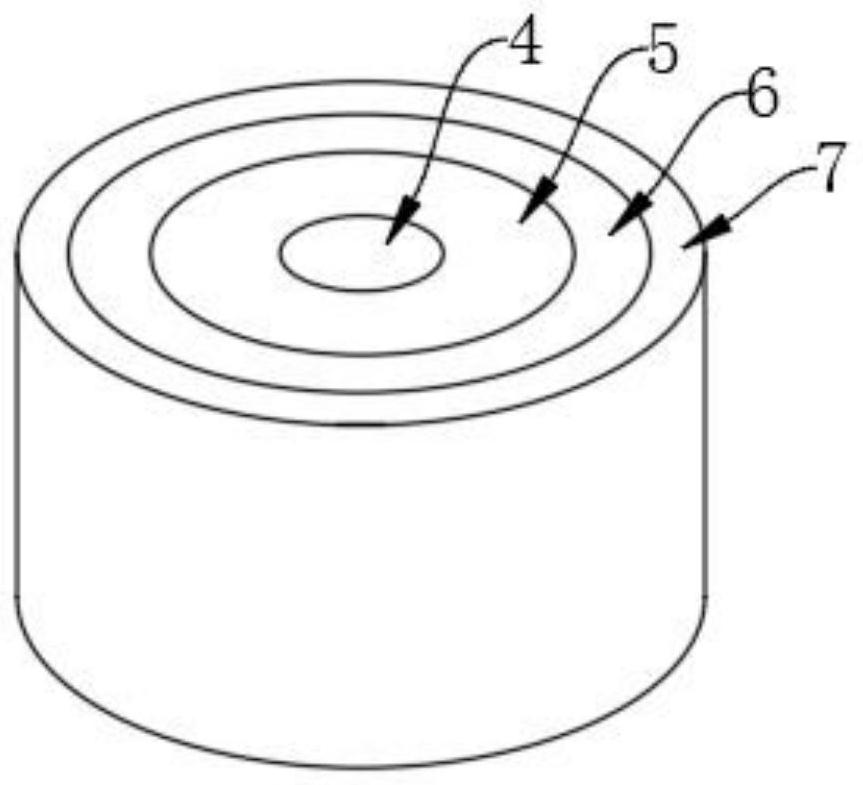

[0032] Further, the permanent magnet assembly 1 is composed of a cylindrical permanent magnet 4, a first annular permanent magnet 5, a second annular permanent magnet 6 and a third annular permanent magnet 7, and the first annular permanent magnet 5 is sleeved on the cylinder Shaped permanent magnet 4, the second annular permanent magnet 6 is sleeved outside the first annular permanent magnet 5, the third annular permanent magnet 7 is sleeved outside the second annular permanent magnet 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com