An intelligent detection method and system based on a mixed process

A mixed process and intelligent detection technology, which is applied in the field of mixed process, can solve the problems of affecting the evaluation result of uniformity and setting inaccurate sampling time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

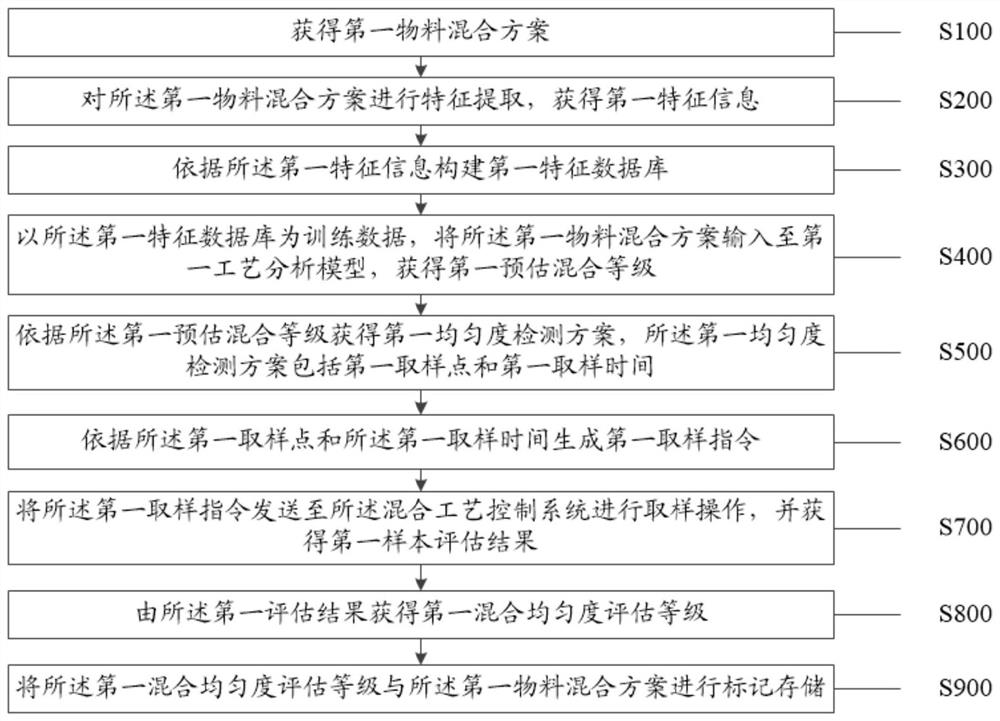

[0025] Such as figure 1 As shown, the embodiment of the present application provides an intelligent detection method based on a mixing process, which is applied to a mixing process control system, wherein the method includes:

[0026] Step S100: Obtain the first material mixing scheme;

[0027] Specifically, the mixing equipment can mix various materials into a uniform mixture, such as mixing cement, sand, gravel and water into concrete wet materials, etc.; it can also increase the material contact surface area. To promote chemical reactions; it can also accelerate physical changes, such as adding granular solutes to solvents, and the dissolution and mixing can be accelerated through the action of mixing machinery. The first material mixing scheme includes the specific scheme of the material mixing process, such as mixing equipment type, material type, equipment running time, mixing process monitoring indicators, material pretreatment, material input method, etc. The first m...

Embodiment 2

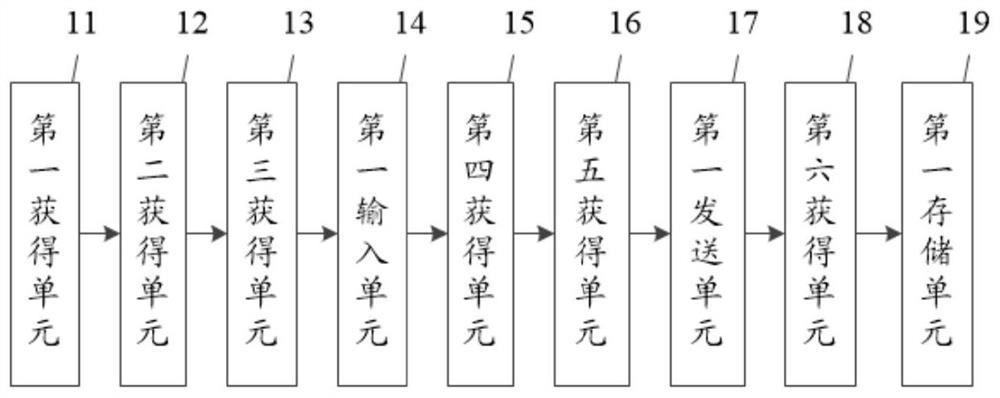

[0085] Based on the same inventive concept as an intelligent detection method based on a mixed process in the foregoing embodiment, the present invention also provides an intelligent detection system based on a mixed process, such as figure 2 As shown, the system includes:

[0086] A first obtaining unit 11, the first obtaining unit 11 is used to obtain a first material mixing scheme;

[0087] A second obtaining unit 12, the second obtaining unit 12 is configured to perform feature extraction on the first material mixing scheme to obtain first feature information;

[0088] A third obtaining unit 13, the third obtaining unit 13 is configured to construct a first feature database according to the first feature information;

[0089] The first input unit 14 is configured to use the first feature database as training data, input the first material mixing scheme into the first process analysis model, and obtain a first estimated mixing level;

[0090] A fourth obtaining unit 15, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com