Mulching film recycling device convenient to maintain

A recycling device and mulching film technology, which is used in collectors, plant protection, plant protection covers, etc., can solve the problems that the surface of the mulching film affects the recycling effect, cannot be recycled and cut, and is inconvenient to disassemble and maintain. Guarantee the stability of recycling and the effect of cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

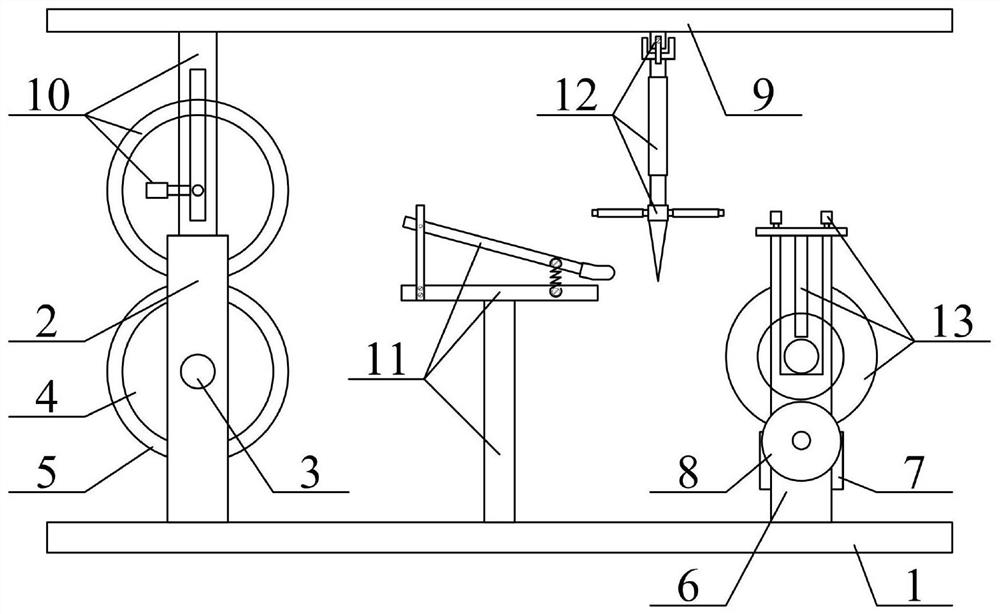

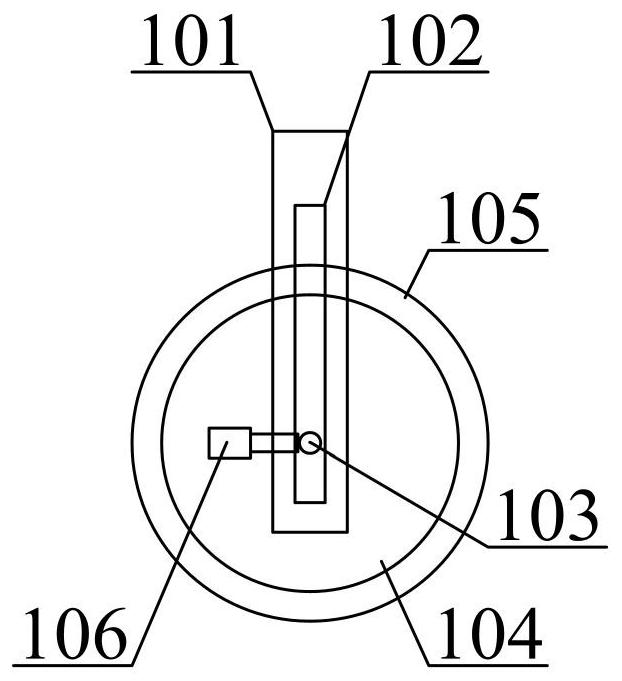

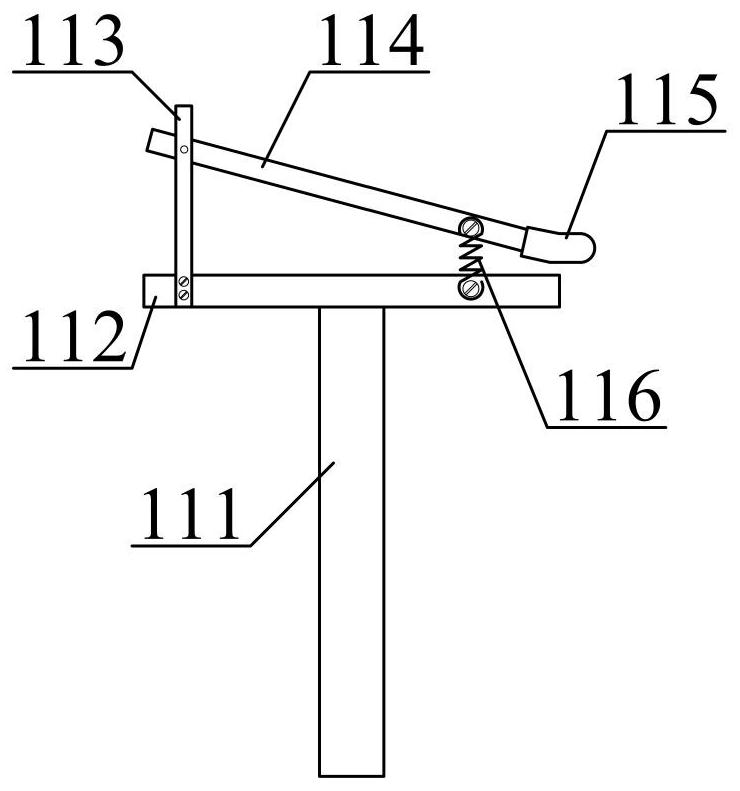

[0033] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a mulch recovery device that is easy to maintain includes a base 1, a wheel frame 2, a wheel shaft 3, a guide wheel 4, a cleaning sheet 5, a machine base 6, a driving motor 7, a driving gear 8 and a protective top plate 9, the described The middle part of the upper left side of the base 1 is bolted to the wheel frame 2; the inner middle part of the wheel frame 2 is connected to the guide wheel 4 through the wheel shaft 3; the outer surface of the guide wheel 4 is wrapped with a cleaning sheet 5; the base 1 The middle part of the upper right side is bolted to the organic base 6; the upper rear part of the base 6 is bolted to the drive motor 7; the output shaft of the drive motor 7 runs through the inside of the base 6, and is keyed to the driving gear 8, It can guarantee the stability of recycling collection operation.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com