Corn planting device

A planting device and corn technology, which is applied to fertilization devices, manual seeding tools, agricultural gas emission reduction, etc., can solve the problems of reduced planting efficiency, slow process, and uncomfortable feeling of planters, so as to improve efficiency, improve accuracy, The effect of convenient placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

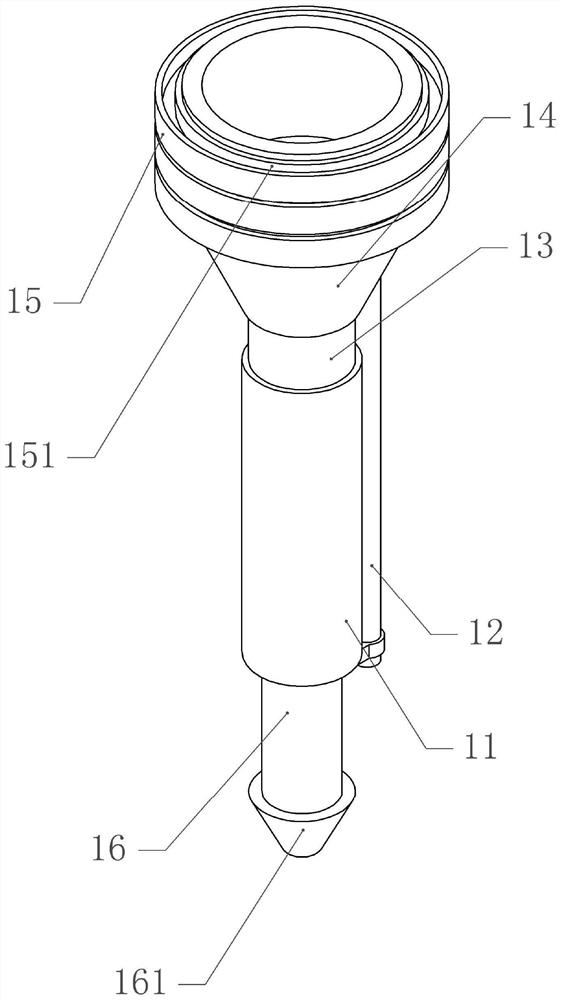

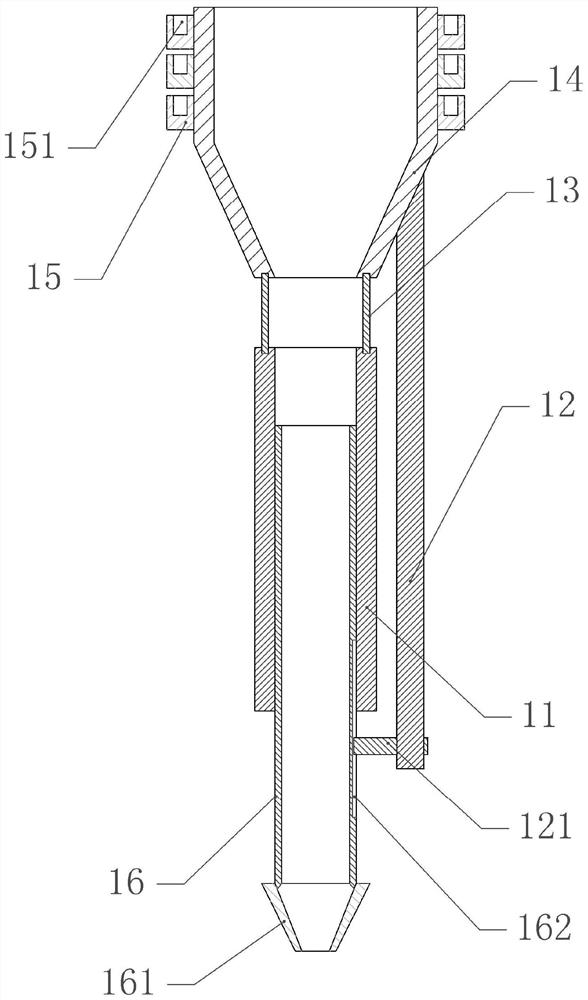

[0029] Basic as attached figure 1 And attached figure 2 As shown, a kind of corn planting device comprises planting box 14 and support pipe 11 successively from top to bottom, and the upper part of planting box 14 is circular, and the bottom of planting box 14 is conical, and the upper part of planting box 14 is connected with coaxial thread Several storage rings 15 are arranged, and the storage rings 15 are evenly distributed along the vertical direction of the planting box 14, and the storage rings 15 are provided with a storage cavity 151 with an upper opening. The storage cavity 151 can be used to store fertilizers and can be used to store planting. In this embodiment, there are three storage rings 15 .

[0030] The support tube 11 communicates with the planting box 14, the upper end of the support tube 11 is fixed with a connecting tube 13, the connecting tube 13 communicates with the supporting tube 11, the upper end of the connecting tube 13 is connected with the bot...

Embodiment 2

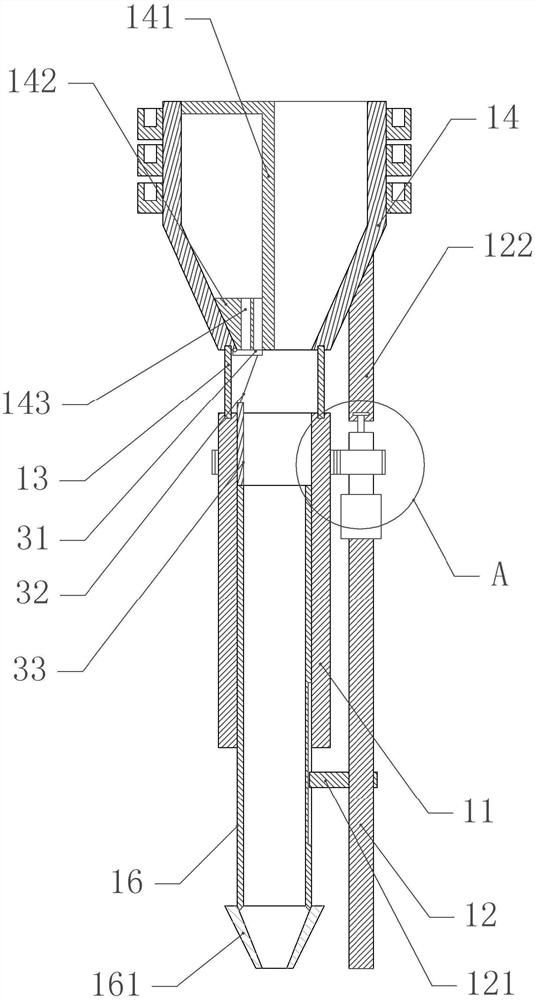

[0038] The difference between embodiment two and embodiment one is that, as attached image 3 And attached Figure 4 As shown, the drive member is fixed on the support shaft 12 by bolts. In this embodiment, the drive member is a motor 21, the body of the motor 21 is fixed on the support shaft 12 by bolts, and the main gear 22 is fixed on the output shaft of the motor 21 by coaxial bolts. A slave gear 23 is fixed on the support tube 11 by coaxial bolts, and the slave gear 23 meshes with the master gear 22 .

[0039] The output shaft of the motor 21 is provided with a connecting rod 24. In this embodiment, the connecting rod 24 is T-shaped. The connecting rod 24 is provided with a connecting shaft 122. The upper end of the connecting shaft 122 is fixedly connected with the planting box 14 bolts. The horizontal section is rotationally connected with the connecting shaft 122 , and the vertical section of the connecting rod 24 is welded with the output shaft of the motor 21 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com