A shelling processing device for shell food

A processing device and food technology, which is applied in the field of food processing, can solve the problems of finger pain, a large amount of crumbs, inconvenient cleaning, laborious and laborious, etc., and achieve the effect of improving efficiency, solving labor and labor, and avoiding labor and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

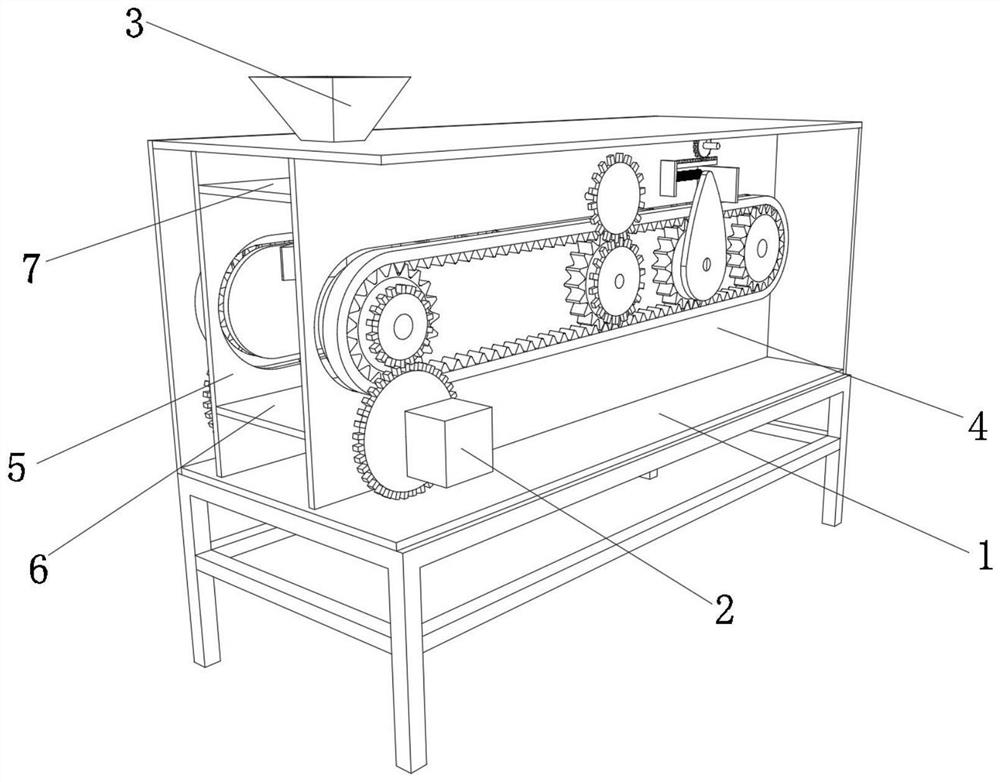

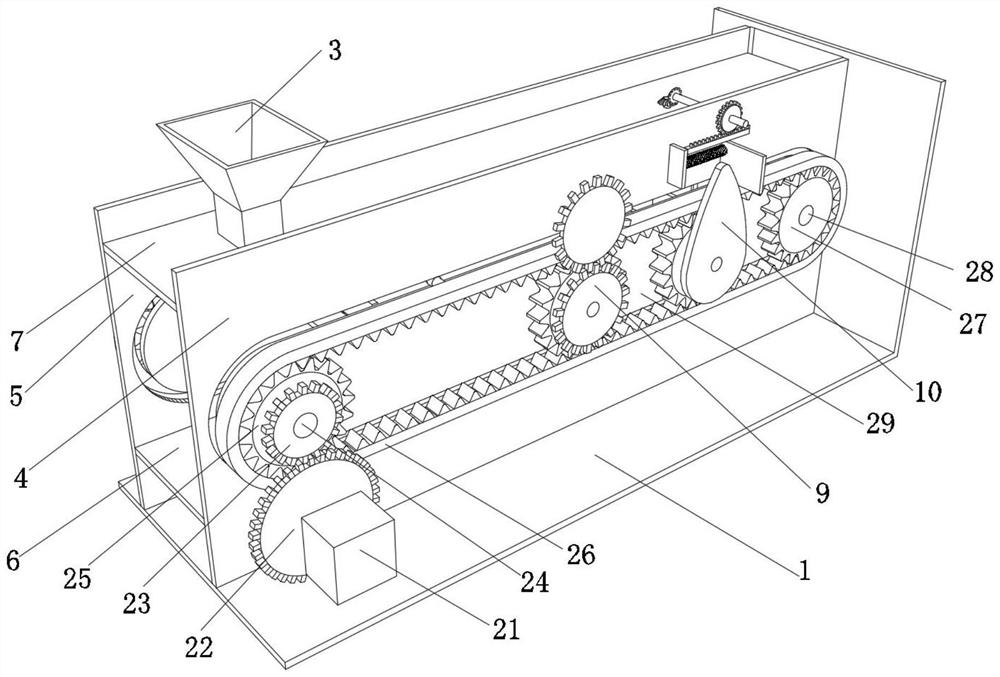

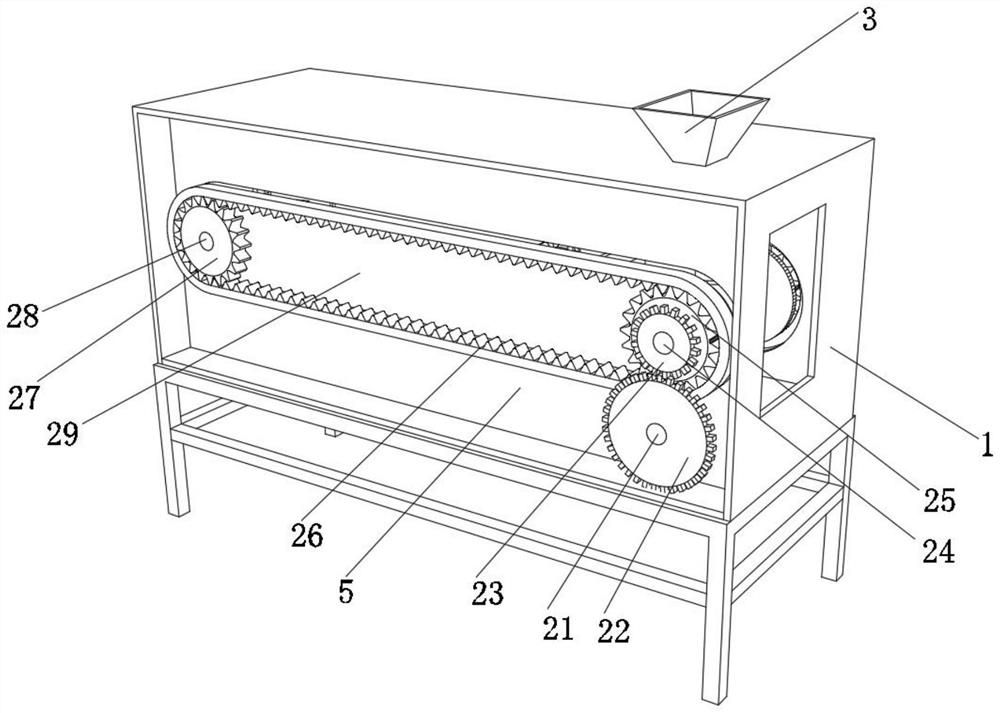

[0032] A shelling processing device for shell food, such as Figure 1-Figure 7 As shown, it includes a shelling processing device for shell food, including an outer box 1, the inner wall of the outer box 1 is provided with a power mechanism 2, the top of the outer box 1 is provided with a feeding mechanism 3, and the bottom wall inside the outer box 1 is provided with a power mechanism 2. The first vertical plate 4 and the second vertical plate 5 are fixedly connected respectively, the first vertical plate 4 is located on the left side of the second vertical plate 5, and the first vertical plate 4 and the second vertical plate 5 pass through the first horizontal plate 6. It is fixedly connected with the second horizontal plate 7 , and the first horizontal plate 6 is located below the second horizontal plate 7 .

[0033] In this embodiment, the power mechanism 2 includes a motor unit 21, the right side of the motor unit 21 is fixedly connected to the inner wall of the outer case ...

Embodiment 2

[0041] like Figure 8 As shown, on the basis of Embodiment 1, in this embodiment, a discharge pipe 61 is inserted into the inside of the first horizontal plate 6, and two limit plates 62 are fixedly connected to the top of the discharge pipe 61. An inclined plate 63 is fixedly connected to the rear of the plate 6 .

[0042] Through the discharge pipe 61 and the inclined plate 63, the fruits and husks produced after the nuts are peeled can be separated and collected, effectively solving the problem that a large amount of debris will be produced by manual peeling, which is very inconvenient for eating and cleaning.

[0043] In this embodiment, the cutting device 9 includes a third meshing gear 91. The surface of the third meshing gear 91 meshes with the surface of the toothed belt 26. The right side of the third meshing gear 91 is fixedly connected with a first rotating gear 92. A second rotating gear 93 is engaged with the surface of a rotating gear 92 , and a rotating rod 94 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com