A robot automatic coating process of aircraft component sealant

An aircraft part, automatic coating technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of difficult control, weak control, and prone to large errors, so as to reduce the amount of testing and make breakthroughs in production. Bottleneck, improve the effect of system parameter debugging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

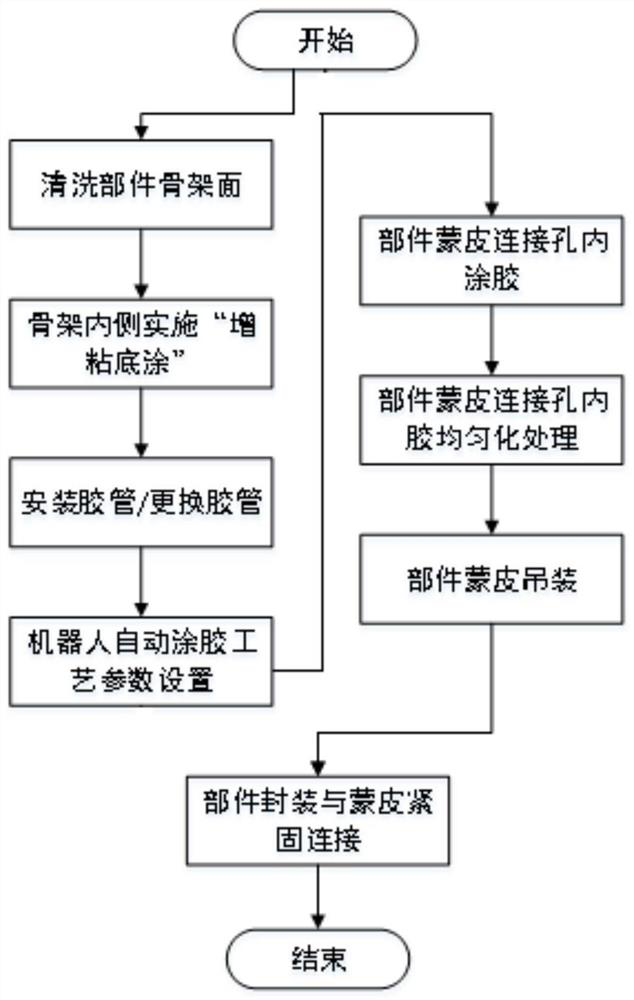

[0058] Such as Figure 1-5 As shown, the present embodiment provides a process for automatic coating of sealants by robots on aircraft parts, comprising the following steps:

[0059] Step S1: Gluing robot preparation;

[0060] Step S2: gluing the aircraft parts skin;

[0061] In step S2, determine the theoretical ratio relational expression of the gluing process during gluing:

[0062]

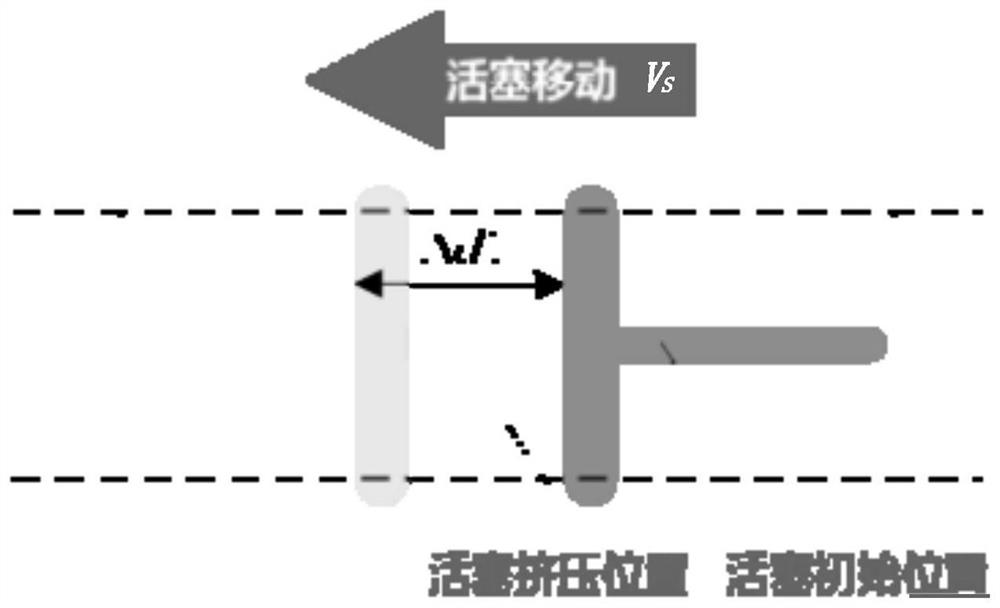

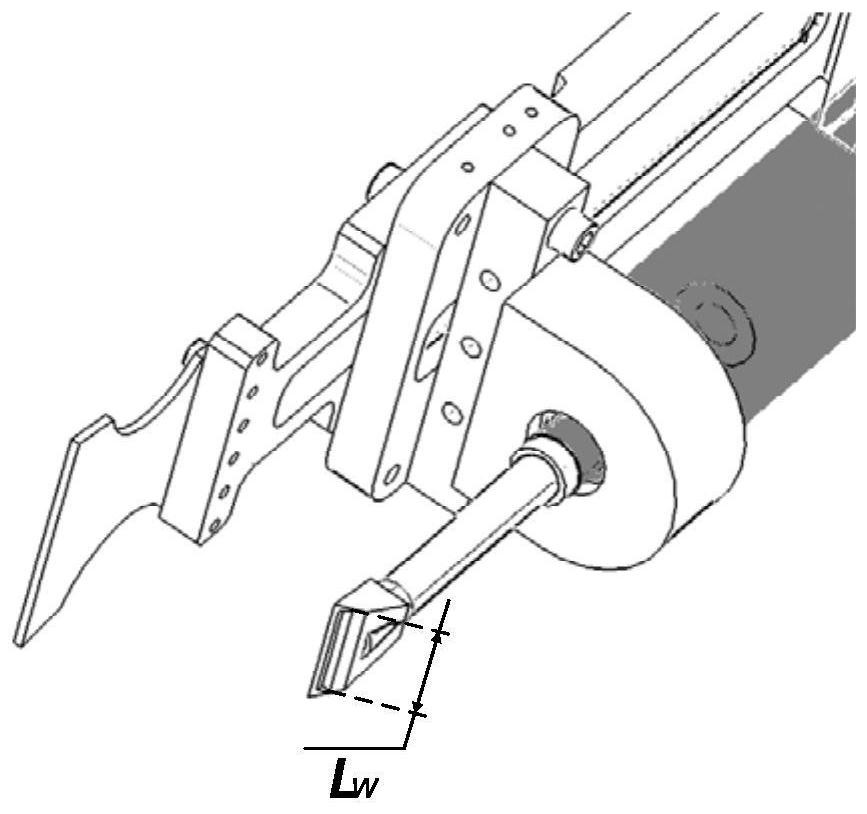

[0063] In formula (1), V L is the linear velocity of the end effector of the robot, V S The moving speed of the push piston for the sealant rubber cartridge, L W is the width of the glue outlet, H 1 For sealant coating thickness, S 1 Push the cross-sectional area of the piston for the rubber cartridge;

[0064] The key parameter configuration of the robot in the automatic coating process of aircraft component sealant is guided according to the theoretical ratio relational expression of the coating process.

[0065] In this embodiment, the theoretical ratio relational expression of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com