Adhesive tape preparation method and adhesive tape structure

A technology of rubber strips and heating equipment, applied in the field of synthetic rubber, can solve the problems of low thickness, toughness, and increased cost, and achieve good flexibility and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

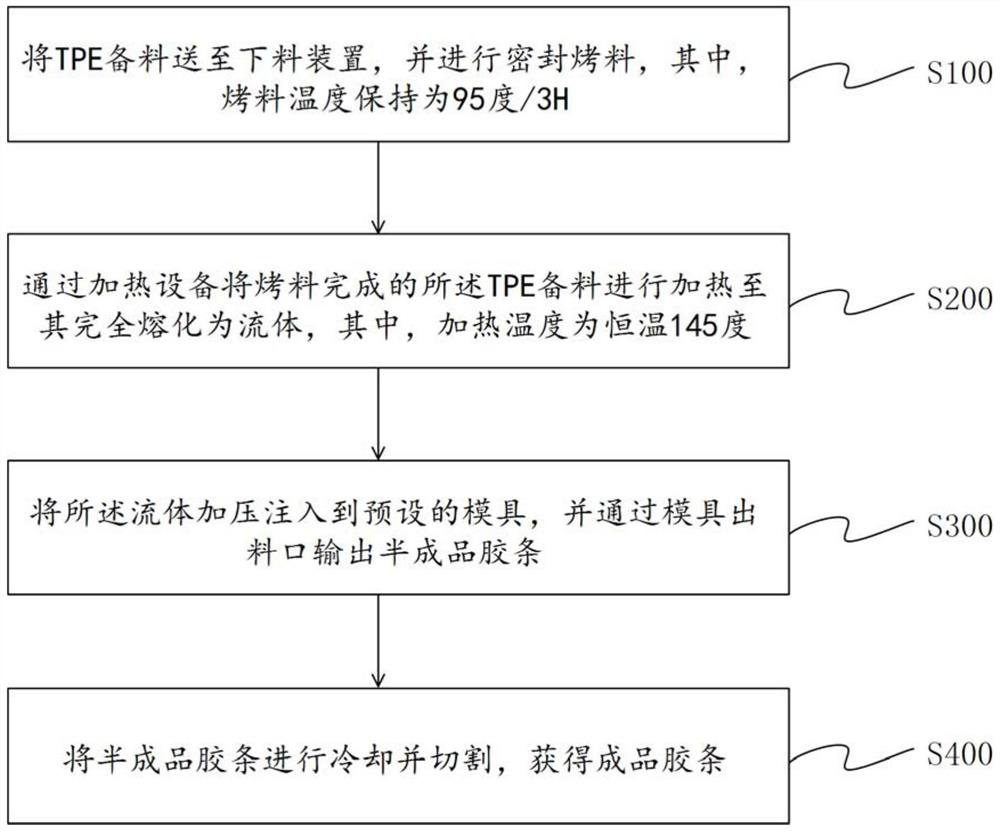

[0042] Refer figure 1 , Shows a method for preparing a strip according to the present embodiment of the invention the step of the flowchart, may specifically include the following steps:

[0043] SlOO, the TPE stock to the cutting means, and sealing frit baked, wherein the baking temperature was maintained at 95 degrees feed / 3H;

[0044] S200, the roasted material by a heating device to complete preparation of the TPE is heated to its complete melting of the fluid, wherein the heating temperature is 145 degrees thermostat;

[0045] S300, the fluid injected under pressure into the mold to a predetermined, semi-finished product output spout and through the die apex;

[0046] S400, the semifinished strip is cooled and cut to obtain the finished strip.

[0047] In an embodiment of the present application, by the TPE stock to the cutting means, and sealing frit baked, roasted material such that heat is more concentrated in the process, fast roasted material, improve efficiency, but a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com