Spinning type straight pulling device for ultrathin grooved pipe

A groove and ultra-thin technology, applied in the direction of presses, pollution prevention methods, chemical instruments and methods, etc., can solve the problems of low yield of materials, easy vibration, and increased economic losses of producers, so as to increase economic losses , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

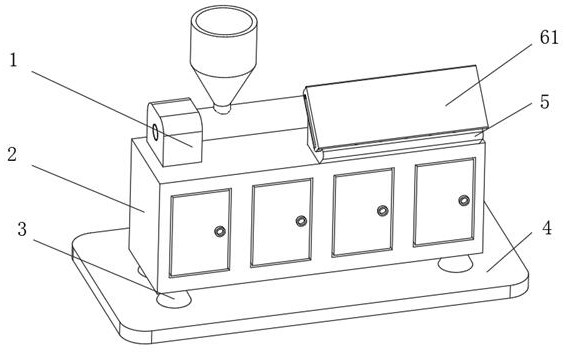

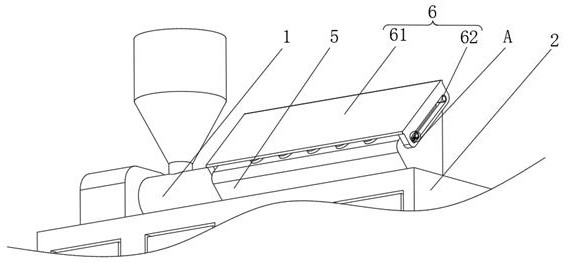

[0024] Example 1, such as Figure 1-5 As shown, an ultra-thin grooved tube spinning straight pull device includes a support plate 4, a body 2 and a stabilizing device 7, the body 2 is located above the support plate 4, and the lower surface of the body 2 is fixedly connected with a support block 3, The upper surface of the body 2 is fixedly connected with the control panel 5 , the upper surface of the body 2 is fixedly connected with the processing assembly 1 , and the stabilizing device 7 is arranged on the surface of the body 2 .

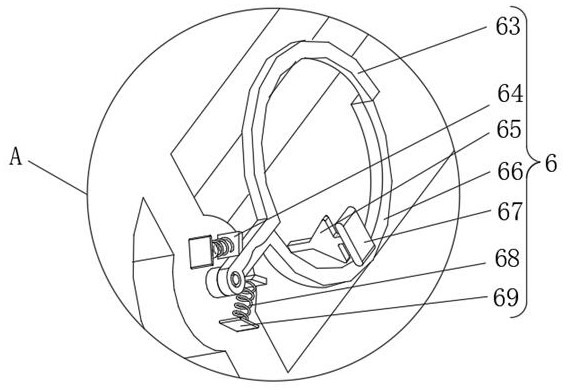

[0025] Let's talk about the specific setting and effect of its stabilizing device 7 and protective device 6 in detail below.

[0026] Such as figure 1 and Figure 5 As shown, the stabilizing device 7 includes a stabilizing rod 72, which is slidingly connected with the inner wall of the body 2. The number of the stabilizing rods 72 is two, and the two stabilizing rods 72 are arranged symmetrically. The inner wall of the stabilizing rod 72 is rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com