Flexible Laminated Film and Display Device Comprising Same

A flexible layer, lamination technology, applied in the direction of lamination device, lamination, identification device, etc., can solve the problem of not being able to meet the flexible display device, etc., and achieve the effects of excellent process performance, excellent pencil hardness, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0111] Preparation Example 1: Preparation of Hard Coat Forming Composition

[0112] Use a stirrer to mix 10 parts by weight of urethane acrylate (10 functions, Miwon Corporation, SC2153), 10 parts by weight of pentaerythritol triacrylate, and 50 parts by weight of nano-silica sol (12nm, 40% solids, catalyst Chemical into company, V8802), 20 weight parts of methyl ethyl ketone (Oi Kakin), 7 weight parts of propylene glycol monomethyl ether (Oi Kao Jin), 2.7 weight parts of photoinitiator (Shiba company, I-184) and 0.3 parts by weight of a leveling agent (BYK Chemie, BYKUV3570), and then filtered using a filter made of PP material to prepare a composition for forming a hard coat layer.

preparation example 2

[0113] Preparation Example 2: Preparation of Hard Coat Forming Composition

[0114] Use a mixer to mix 5 parts by weight of urethane acrylate (10 functional, Meiyuan Special Chemicals, SC2153), 37 parts by weight of pentaerythritol triacrylate, 20 parts by weight of propylene glycol monomethyl ether, 2.7 parts by weight of light An initiator (Shiba, I-184) and 0.3 parts by weight of a leveling agent (BYK Chemie, BYKUV3570) were filtered using a filter made of PP to prepare a composition for forming a hard coat layer.

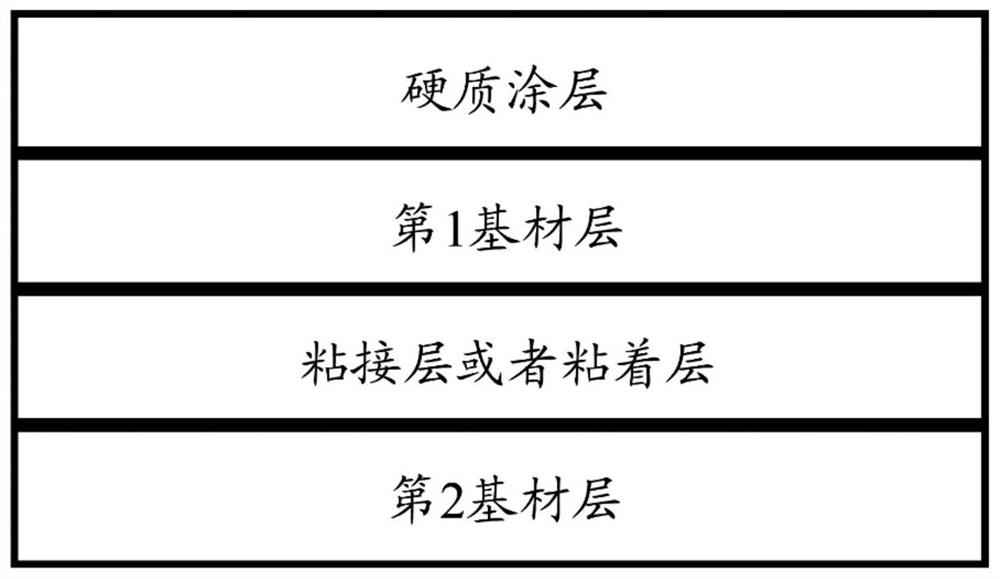

[0115] Examples and Comparative Examples: Preparation of Hard Coated Lamination Films

Embodiment 1

[0117] A laminated film was prepared by bonding a polyimide film (30 μm, first substrate layer) and a polyimide film (40 μm, second substrate layer) with an acrylic adhesive layer (5 μm thickness). Then, the composition of Preparation Example 1 was coated on the first substrate layer so that the thickness after hardening was 10 μm, and then the solvent was dried and UV hardened to form a hard coat layer, thereby producing a hard coat laminate membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com