Dosing device for canned fruit production

A technology of canned fruit and dosing device, which is applied in packaging, liquid bottling, transportation and packaging, etc. It can solve the problems of lower juice liquid level, errors and unreasonable filling dosage, and achieve accurate compensation and economical improvement. Benefits, the effect of improving feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

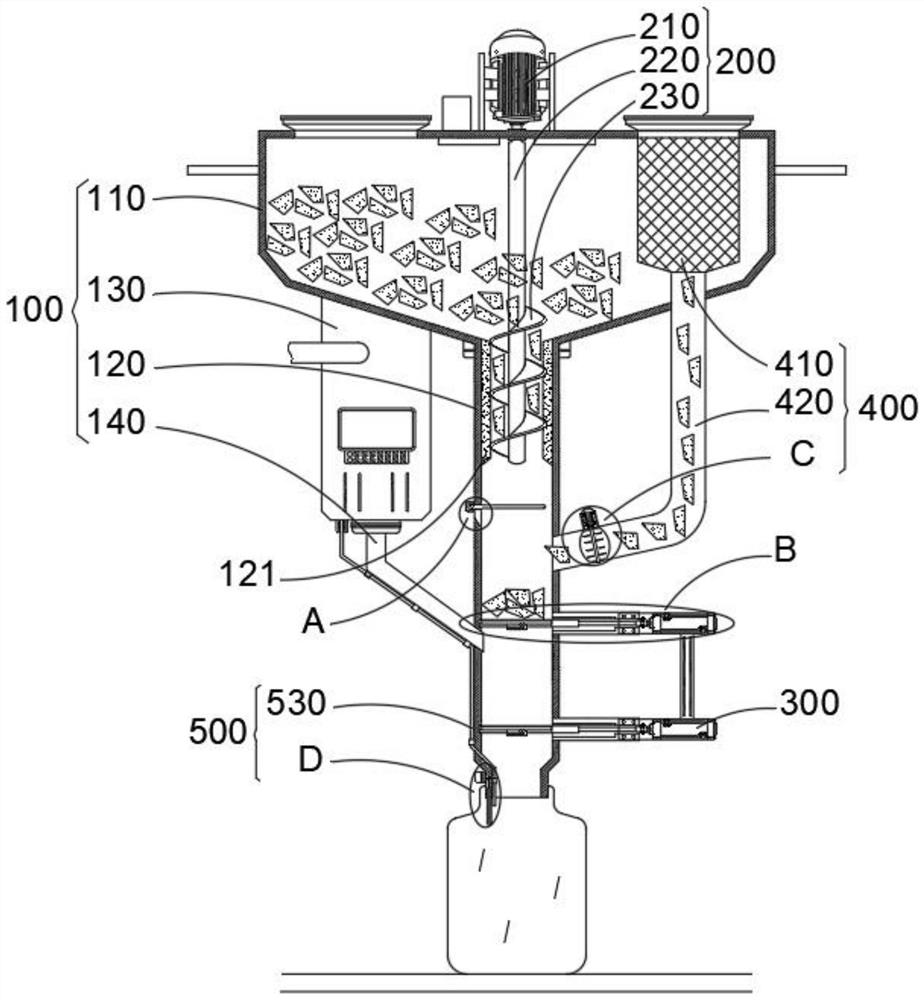

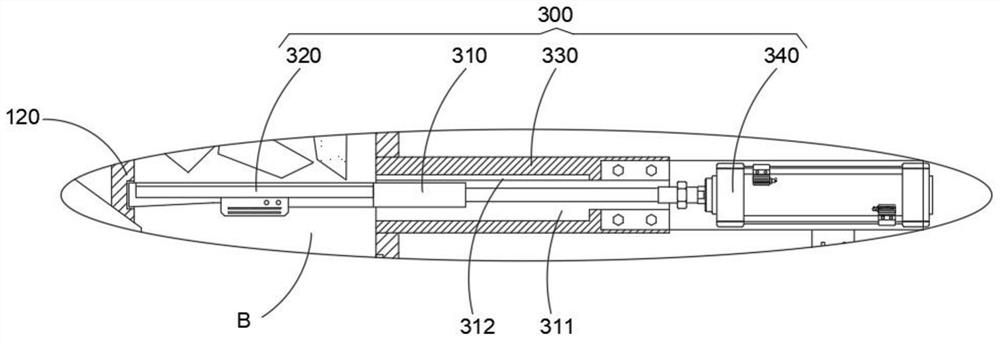

[0045] combine Figure 1-8 As shown, the quantitative device for canned fruit production provided by the present invention includes: a filling mechanism 100, an initial measuring mechanism 200, a compounding mechanism 300, a feeding mechanism 400 and a liquid replenishing mechanism 500,

[0046]The filling mechanism 100 includes a storage box 110 for storing fruit pulp, a discharge cylinder 120 connected to the storage box 110 for quantitatively discharging the pulp, a liquid storage tank 130 for storing canned fruit juice, and a liquid storage tank 130 connected to the liquid storage box 130 for supplying fruit juice. The liquid discharge pipe 140 for the quantitative discharge of fruit juice, and mechanisms such as observation windows, manholes, feeding ports and installation racks are also provided on the material storage box 110, which is convenient for the multifunctional use of the material storage box 110. Corresponding to the elevator, when there is a filling bottle at...

Embodiment 2

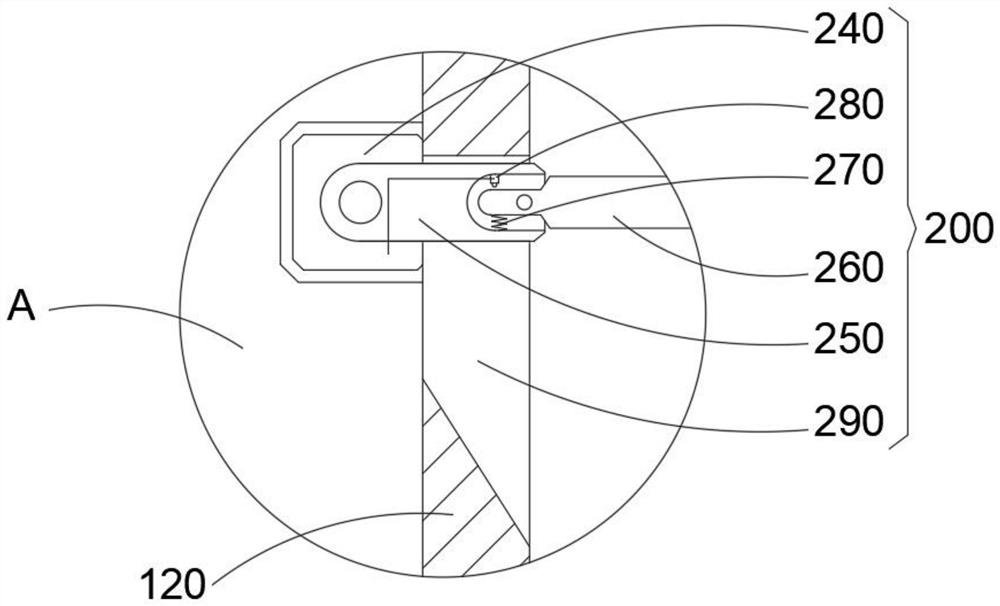

[0054] combine figure 1 As shown, on the basis of Embodiment 1, the inner wall of the top of the discharge cylinder 120 is provided with a lining ring 121, and the lining ring 121 is provided with a side groove for accommodating the tooth edge of the spiral piece 230, through which the lining ring 121 can further Improve the tightness between the spiral piece 230 and the discharge cylinder 120, the outer side of the lining ring 121 is kept close to the inside of the discharge cylinder 120 as the shape of the discharge cylinder 120 changes, and the inner cavity of the lining ring 121 is Cylindrical, the pulp is evenly discharged when the spiral piece 230 rotates. The inner lining ring 121 adopts a food-grade soft rubber pad, and the inner side is provided with anti-skid lines. When the screw piece 230 does not rotate, it remains still, which is convenient for the control of the discharge, so that the pulp is accurately separated in batches, and it is convenient for continuous f...

Embodiment 3

[0058] combine figure 1 As shown, in the above-mentioned embodiment, an ultraviolet lamp group, a heating lamp board and an additive box are also provided in the material storage box 110. On the inner wall of the box 110 or the rotating shaft 220, in order to prevent the pulp from contacting the ultraviolet light board to affect the irradiation effect, a screen frame plate can be arranged outside the ultraviolet lamp board to isolate the contact of the fruit pulp, and the sterilization effect is better. The top of the box 110 can provide heat preservation and a certain degree of drying effect, which is convenient for the diversified use of the storage box 110, thereby improving the practicability of the device. The additive box can spray additives on demand, and further adjust and adjust the canned fruit. Anti-corrosion treatment, choose to use, the effect is better.

[0059] Further, the material storage tank 410 is installed in the material storage box 110, and the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com