Anti-deformation mold pressing device for disc spring tempering

An anti-deformation, disc spring technology, applied in the field of disc spring processing, can solve the problems of small scope of application, insufficient versatility, and inability to adjust the inclination angle according to needs, so as to achieve the effect of improving versatility and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

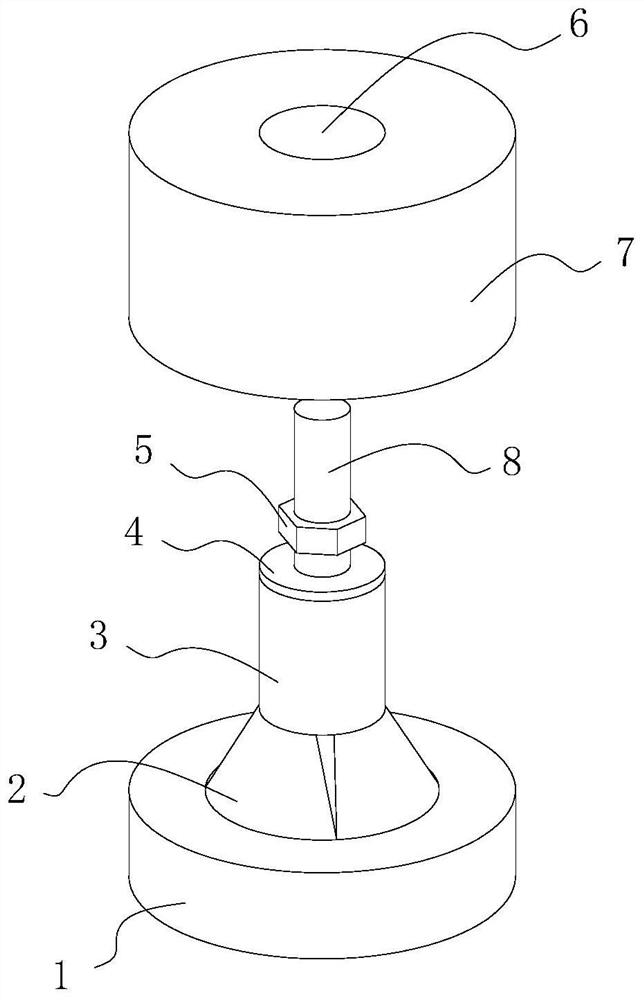

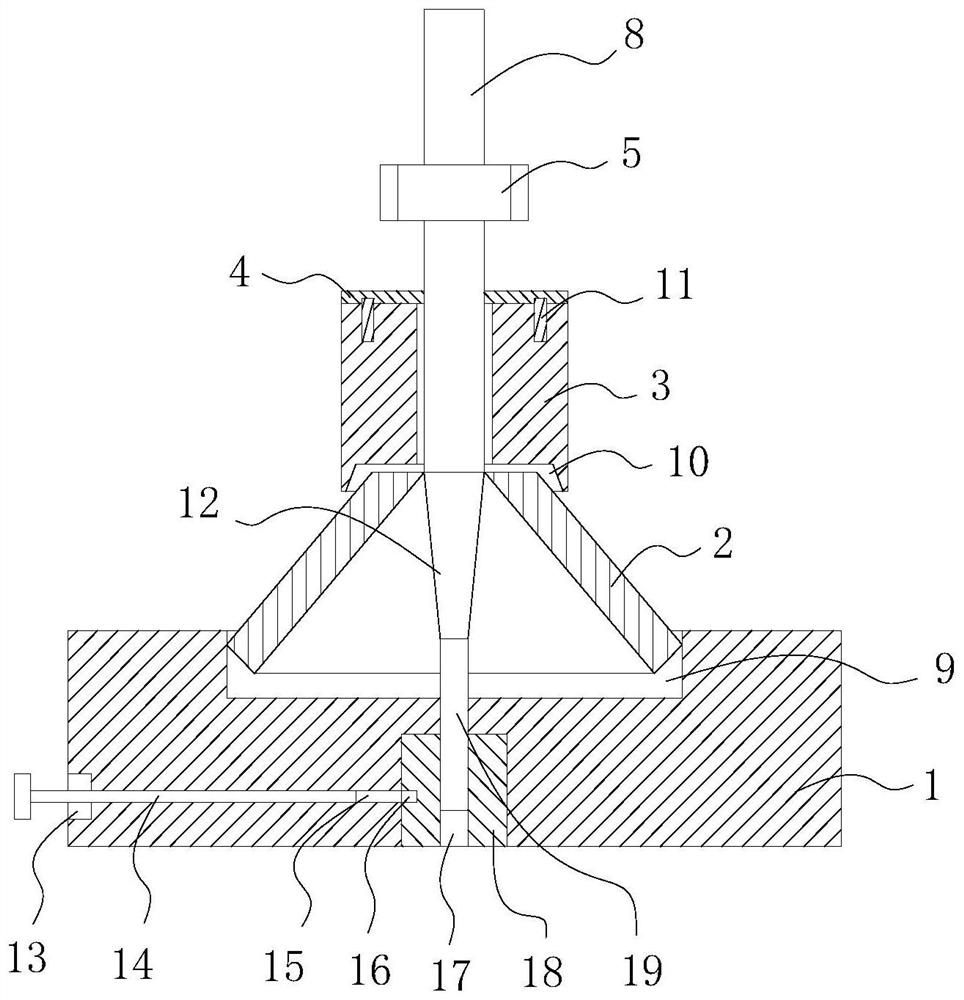

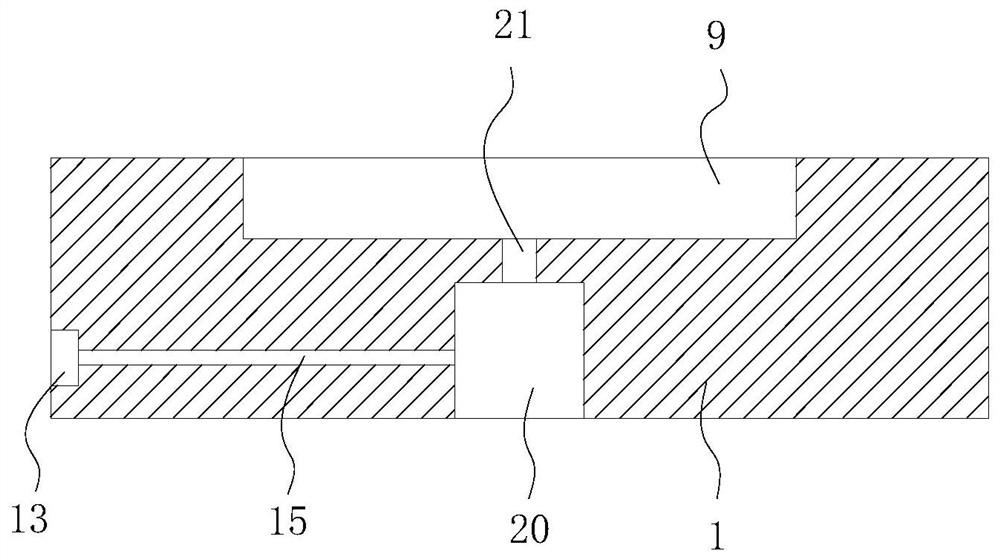

[0027] Example 1: See Figure 1 to Figure 5 , the present invention provides a technical solution: a disc spring tempering anti-deformation molding device, including a base 1, a groove 9 is opened in the middle of the upper surface of the base 1, and a number of narrow upper and lower wide grooves are arranged in the groove 9. The arc-shaped block 2 used to support the disc spring, one end of the arc-shaped block 2 in the groove 9 is hingedly connected with the base 1, the groove 9 is a circular structure, and the groove 9 provides installation space for the lower end of the arc-shaped block 2, Simultaneously play the effect of limiting the position of the lower end of the arc block 2 .

[0028] A tapered column 12 with a wide top and a narrow bottom for supporting the upper end of the arc-shaped block 2 is provided between several arc-shaped blocks 2. The lower end of the tapered column 12 is fixedly connected with a second stud 19, and the second stud 19 is connected to the ...

Embodiment 2

[0036] Example 2: see Figure 6 , a tapered sleeve 27 with a wide top and a narrow bottom for supporting the upper end of the arc-shaped block 2 is provided between several arc-shaped blocks 2, the tapered sleeve 27 is internally threaded with a threaded rod 28, and the lower end of the threaded rod 28 is threaded with the base 1 , when the tapered sleeve 27 is worn, the tapered sleeve 27 is removed from the threaded rod 28 and replaced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com