Protective plate for coal falling opening of circulating fluidized bed boiler and preparation device and method of protective plate

A technology of circulating fluidized bed and preparation equipment, which is applied in the field of tableware, and can solve problems such as aggravated wear, low hardness of heat-resistant steel, and wear of protective plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

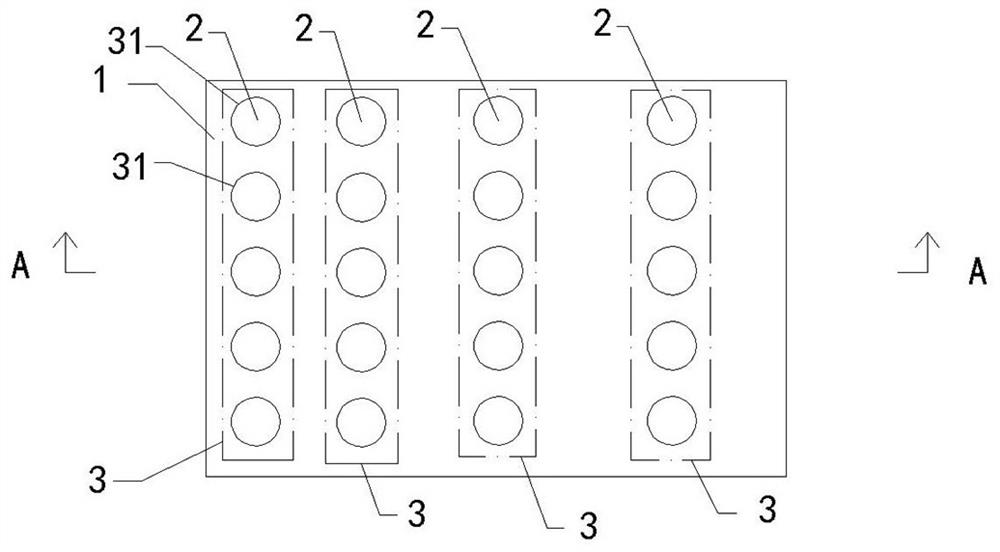

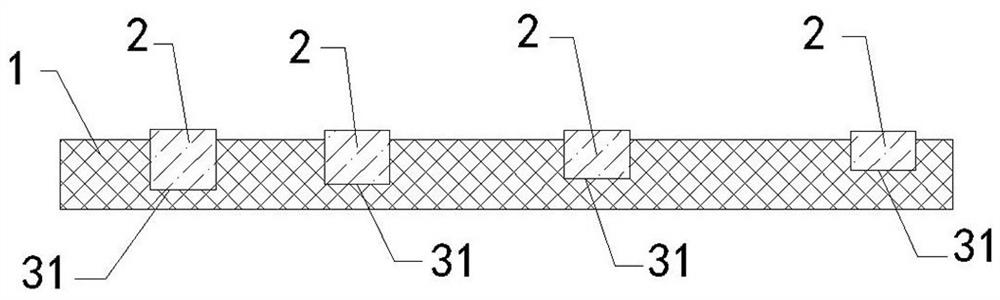

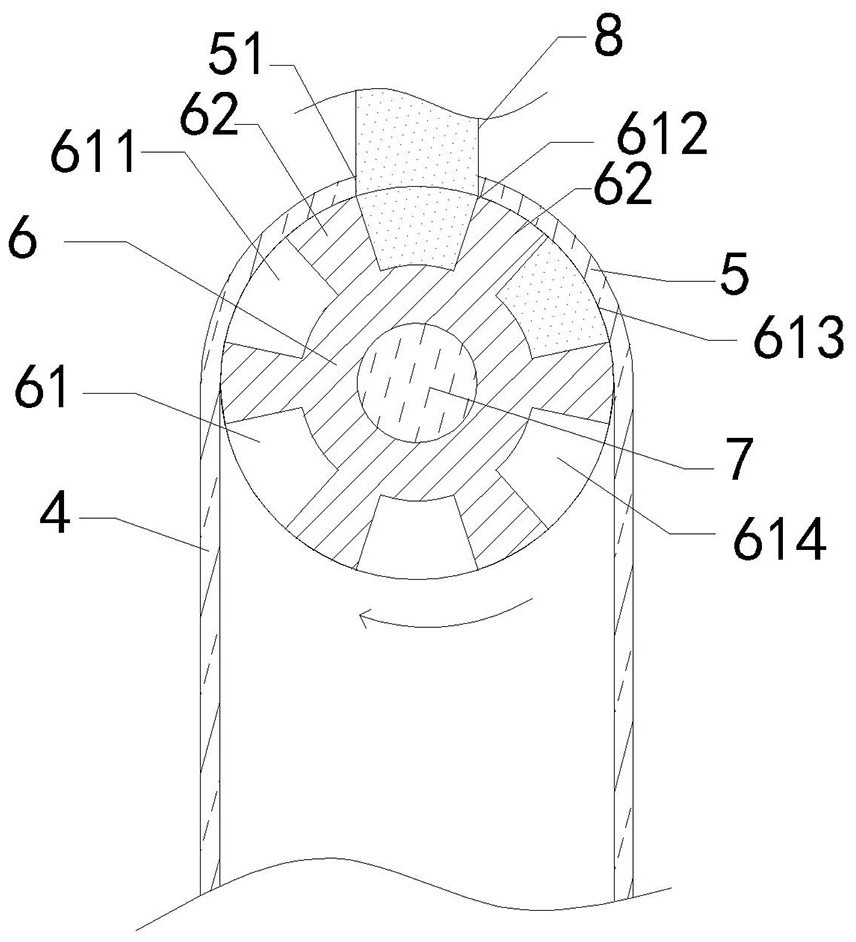

[0031] see Figure 1-2 , This embodiment provides a protective plate for the coal drop port of a circulating fluidized bed boiler, including a heat-resistant steel base plate 1 and a reinforcing filler 2 .

[0032] The heat-resistant steel substrate 1 is usually a rectangular parallelepiped plate, and its material is usually heat-resistant steel 0Cr25Ni20 to adapt to the high-temperature environment inside the boiler. At the same time, the unit price of the heat-resistant steel 0Cr25Ni20 is relatively low, thereby effectively reducing the cost of the heat-resistant steel substrate 1 .

[0033] The upper surface of the heat-resistant steel substrate 1 is sequentially provided with a plurality of linear groove arrays 3 from left to right, and generally speaking, all the linear groove arrays 3 are parallel to each other. The linear groove array 3 includes a plurality of grooves 31 sequentially arranged along a straight line. By arranging a plurality of linear groove arrays 3 , t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com