Method for producing free forming part based on low-temperature supersonic spraying and application

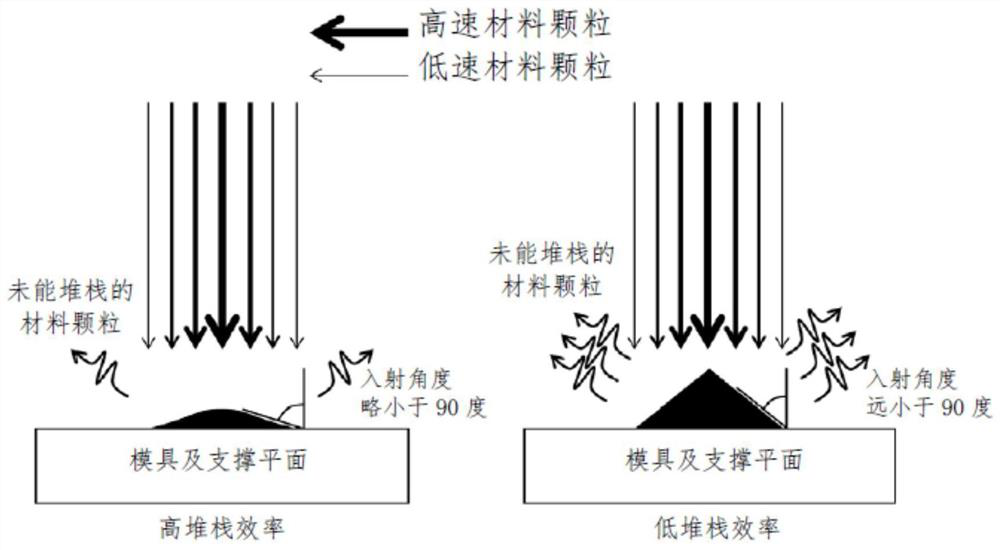

A technology of supersonic spraying and forming parts, which is applied to aircraft parts, pressure inorganic powder coating, fuselage, etc., which can solve the problems of rising production costs and inability to reuse, and achieve reduced production costs, increased stacking efficiency, and reduced waste of materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] As a specific embodiment of the present invention, as a specific embodiment, the low-temperature supersonic spraying of the present invention produces a large number of free-form parts by manufacturing a helmet on a mold as a specific embodiment of the present invention:

[0042] Step 1: The process of spraying a low melting point release layer:

[0043] The mold is made of hard material, which is generally selected as metal, ceramic or composite material. In this embodiment, the material of the helmet die is die steel H11. Before spraying the low-melting point release layer, the powder storage tank of the low-temperature supersonic spray gun is filled with low-melting point materials, and the low-melting point materials are generally selected as metal or composite materials. In this embodiment, the low melting point material is a low melting point alloy containing tin (Sn). Then, spray a layer of low melting point material on the mold as a release layer. In this emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com