A Genetic Scheduling Method Based on Combination Production and Equipment Failure Constraints

A technology of equipment failure and scheduling method, which is applied in the field of automatic control, can solve problems such as machine failure, and achieve the effect of shortening time and shortening scheduling delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

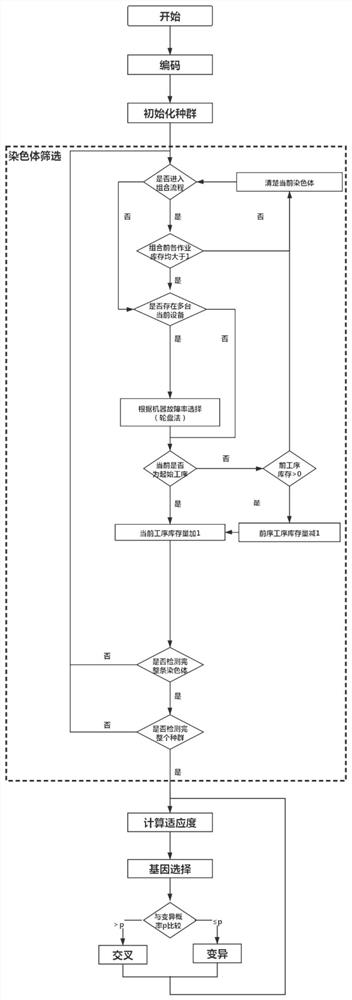

[0044] like Figure 1-2 As shown, a genetic scheduling method based on combined production and equipment failure constraints includes the following steps:

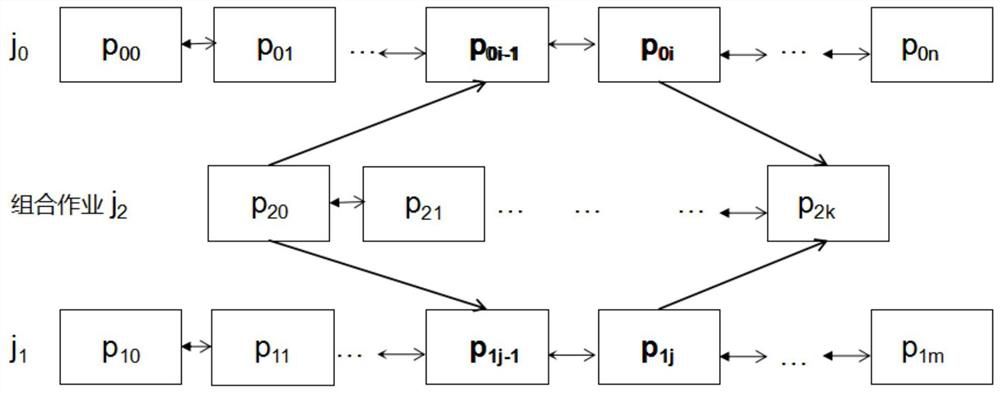

[0045] Step 1. Propose a job constraint graph model, and use a multi-pre-order job constraint graph to clearly represent the correlation and dependencies between each job; the job constraint graph model is a bidirectional directed graph, that is, a virtual j 2 Job represents a combined production job, node P ij represents the jth process of the ith job, and each node has one or more forward edges connecting each job; P 0i and P 1j respectively represent the actual work j 0 and j 1 virtual combined production process, avoid repeated scheduling during scheduling, that is, whether a process is running on a machine at a certain time, it needs to depend on the inventory of the direct previous process of the process. Schedule, otherwise it is not allowed to be scheduled at this time, such as formula 1:

[0046] ,

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com