Method for manufacturing semiconductor structure

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as increasing the resistance value of metal silicides and reducing the performance of semiconductor structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

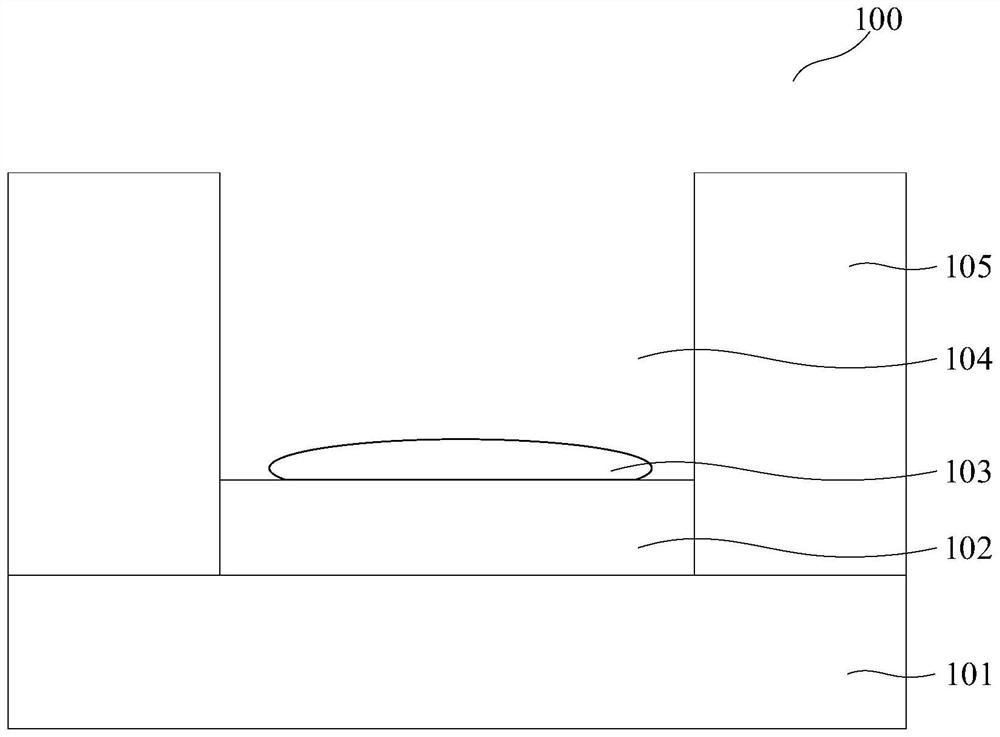

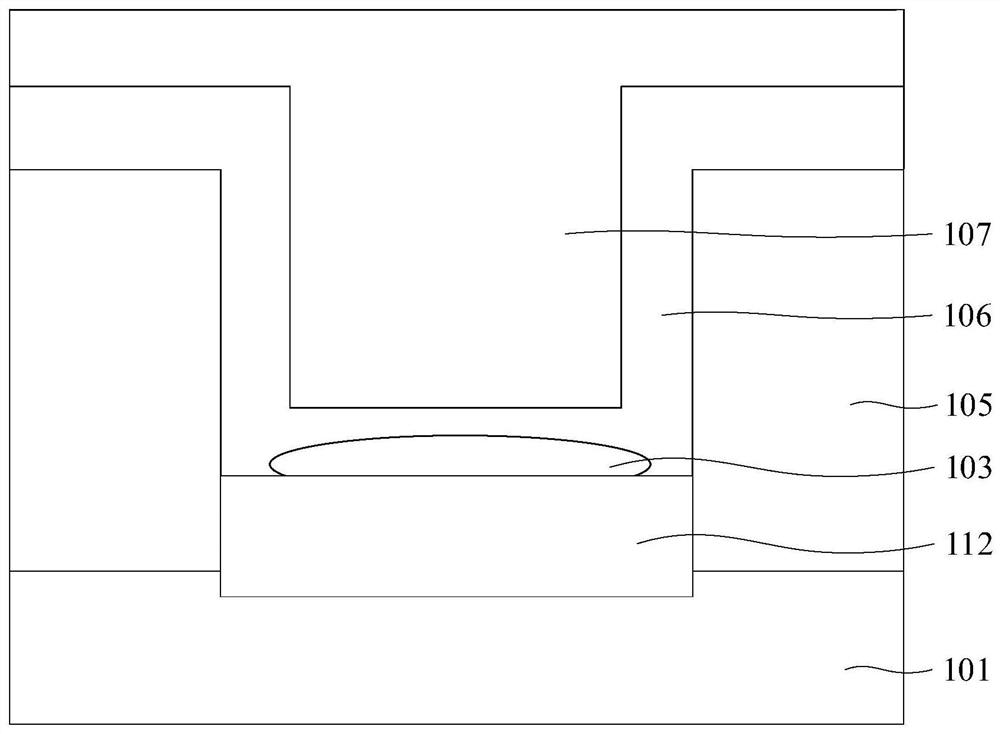

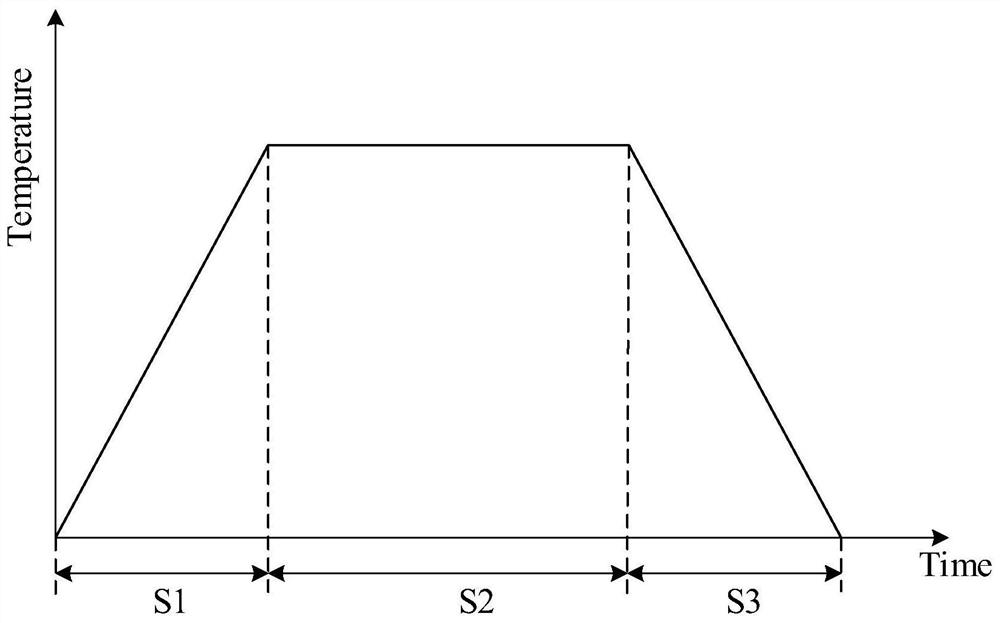

[0025] It can be seen from the background art that the product yield of the existing semiconductor structure still needs to be improved. figure 1 and figure 2 It is a structural schematic diagram corresponding to each step of a manufacturing method of a semiconductor structure. image 3 yes figure 2 The corresponding time-temperature schematic diagram.

[0026] combine figure 1 and figure 2 , to analyze the manufacturing method of the semiconductor structure:

[0027] refer to figure 1 , a substrate 100 is provided, and the substrate 100 includes a metal layer 102 and an oxide 103 on the surface of the metal layer 102 .

[0028] The base 100 also includes a substrate 101 and a dielectric layer 105 on the surface of the substrate 101 , and a trench 104 exposing the substrate 101 is located in the adjacent dielectric layer 105 , and the metal layer 102 is located on the substrate 101 in the trench 104 .

[0029] refer to figure 2 , for the substrate 100 (reference f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com