Belt conveyor and drum for a belt conveyor

A technology of belt conveyors and rollers, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as downtime of belt conveyor facilities, belt damage, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

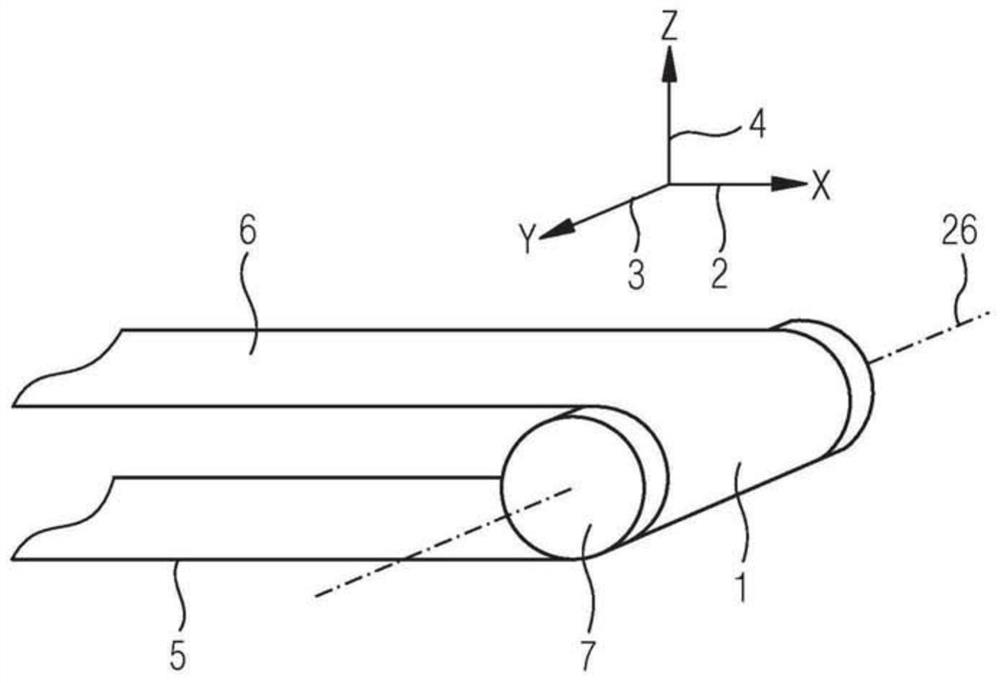

[0035] exist figure 1 A section of a belt conveyor is shown in . It shows the rollers 7 by which the belt 1 is deflected. The belt comprises a portion called upper loop 6 and a portion called lower loop 5 . The running direction of the belt is indicated by the X-axis as the belt longitudinal axis. The belt transverse axis 3 corresponds to the y-axis, and the z-axis 4 runs counter to the force of gravity.

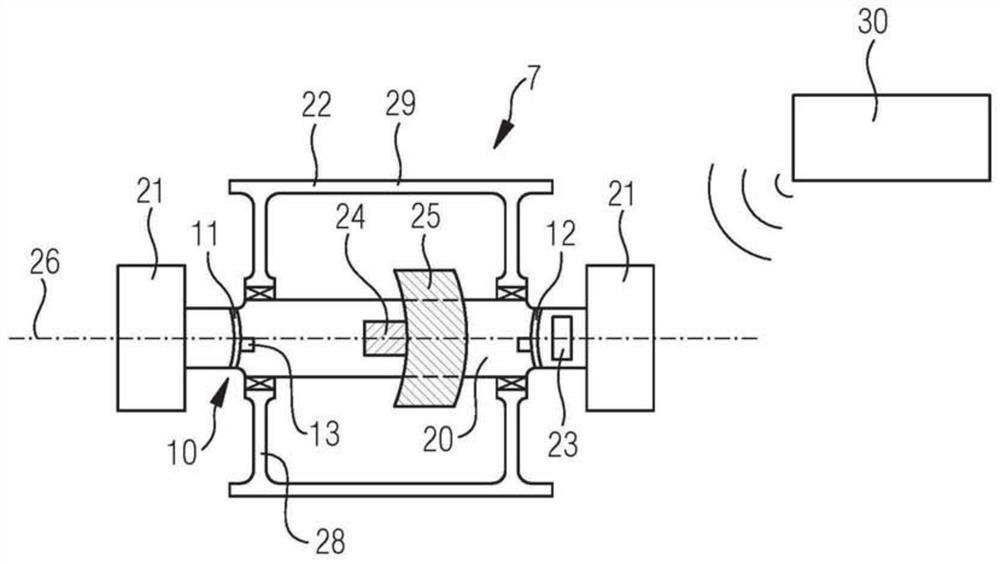

[0036] figure 2 The drum 7 is shown in more detail in . The drum 7 comprises a drum body 22 which is supported on a drum mandrel 20 . The drum mandrel 20 is supported on both sides by bearings 21 . The axis of rotation of the drum mandrel is indicated with 26 .

[0037] For monitoring tasks, the drum 7 is equipped with a sensor device 10 for receiving measurement signals, a signal processor 24 for signal processing and a communication device 23 . The received and generated data may be received by associated central data processing means 30 .

[0038] In particular,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com