Portable forestry scarifier

A kind of loosening machine and portable technology, applied in agricultural machinery and tools, agricultural, land preparation machinery, etc., can solve the problems of single working mode, inability to adjust forest adaptability, difficulty in both high loosening efficiency and versatility, and achieve Large single loosening area, improved loosening quality, high passability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

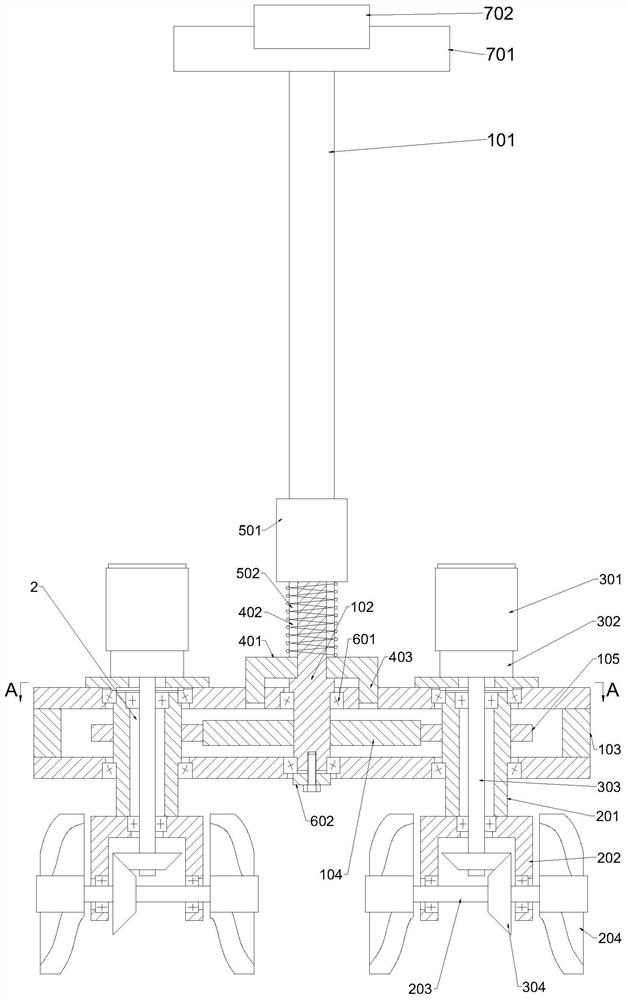

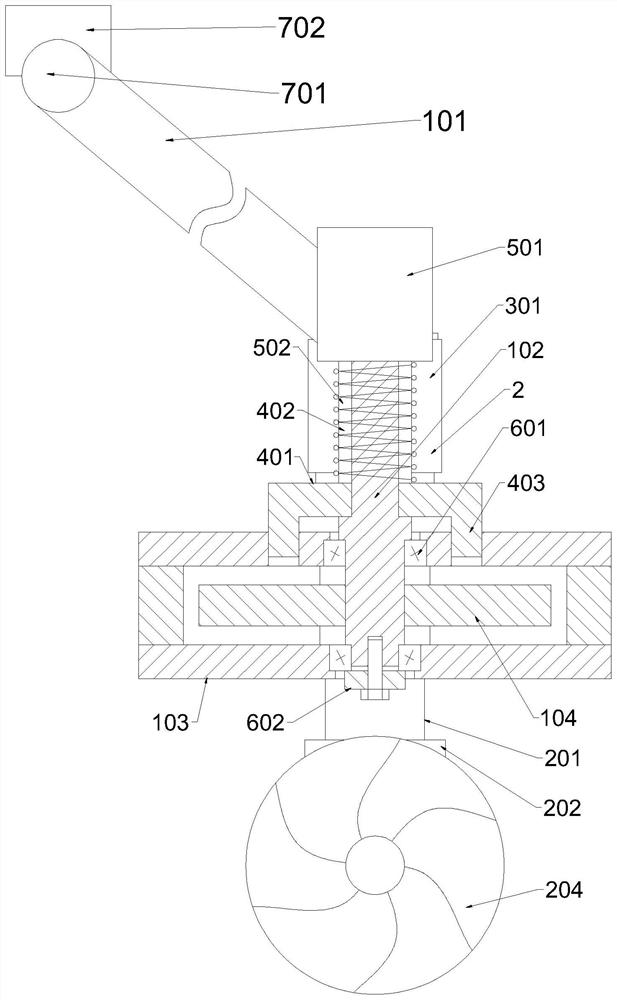

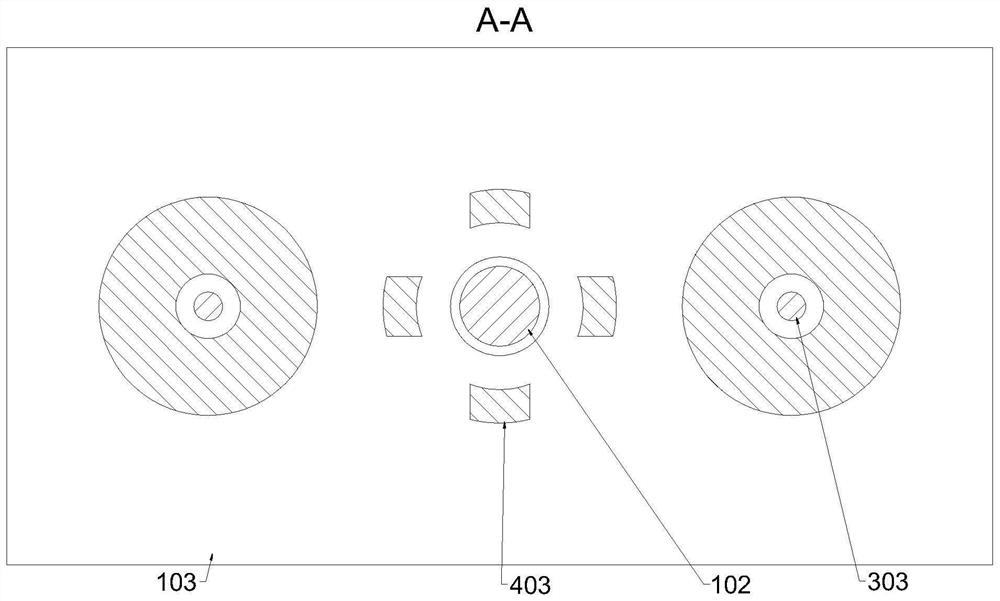

[0026] Such as figure 1 As shown, a kind of portable forestry ripper provided by the present invention comprises: pull rod 101, steering shaft 102 mounting box 103, first gear 104 and two soil turning mechanisms 2, pull rod 101; Steering shaft 102 and described pull rod 101 One end is fixedly connected; the installation box 103 is provided with a first through hole, and the shaft body of the steering shaft 102 is connected with the bearing of the installation box 103; the first gear 104 is arranged in the installation box 103, and the first gear 104 is fixedly connected to the steering shaft 102 shaft body; two soil turning mechanisms 2 are distributed on both sides of the first gear 104, and the installation box 103 is respectively provided with an installation through hole on both sides of the first gear 104, and the two soil turning mechanisms 2 are respectively bearing connected to the first gear 104. In the installation through holes on both sides of the gear 104, the two...

Embodiment 2

[0031] On the basis of Embodiment 1, after the working mode of the whole scarifier is switched, the working direction of the scarifier does not change after the tiller mechanism 2 rotates 180 degrees.

[0032] Such as figure 1 and 2As shown, wherein, the soil turning mechanism 2 includes a connecting pipe 201, a fork frame 202, a transmission shaft 203, a soil loosening wheel 204 and a power unit, the outer wall of the connecting pipe 201 is connected with the installation through-hole bearing, and the second The second gear 105 is fixedly connected to the body of the connecting pipe 201, and the connecting pipe 201 is positioned at one end of the lower side of the installation box 103 and is fixedly connected with the fork frame 202, the fork frame 202 is connected with the transmission shaft 203 bearings, and the soil loosening wheel 204 is fixedly connected with the transmission shaft 203, and the transmission shaft 203 is tooth-connected with a power device, and the power...

Embodiment 3

[0035] On the basis of Embodiment 2, in order to ensure that the scarifier is switched between working modes, the power device is always connected to the transmission device.

[0036] Such as figure 1 As shown, wherein, the power device includes a motor 301, a reducer 302 and an output shaft 303, the motor 301 is fixedly connected to the upper surface of the installation box 103, the output end of the motor 301 is connected to the input end of the reducer 302 connection, the output end of the reducer 302 is connected to the output shaft 303, the fork frame 202 is provided with a second through hole, the output shaft 303 is coaxial with the connecting pipe 201, and the output shaft 303 passes through the connection The pipe hole and the second through hole of the pipe 201 are gear-connected with the transmission shaft 203 through the bevel gear 304 , and the shaft body of the transmission shaft 203 is connected with the inner wall of the connecting pipe 201 with a bearing.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com