Ink application device, control device for ink application device, and ink application method

A technology of coating device and control device, applied in printing device, printing and other directions, can solve the problems of unable to exert sufficient modification effect, unable to form ink film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

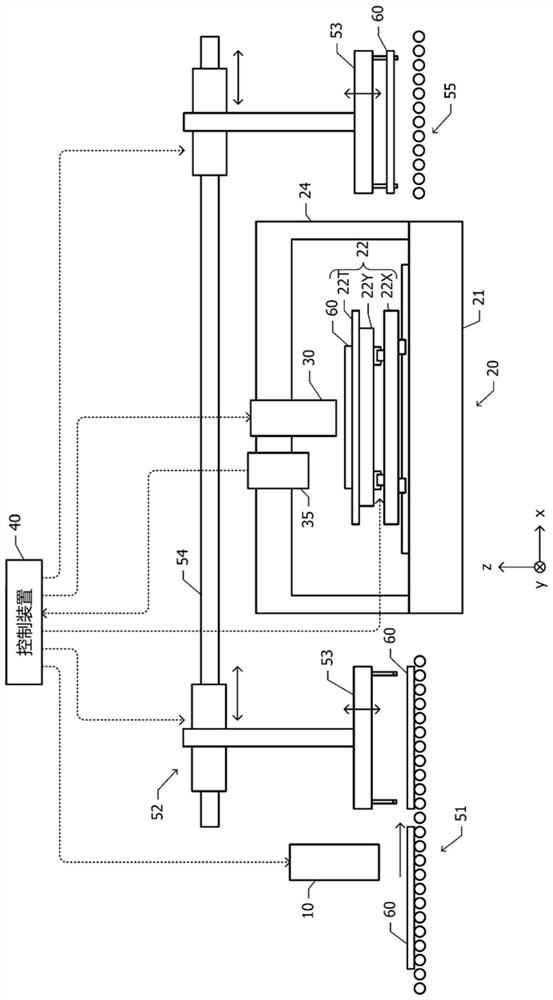

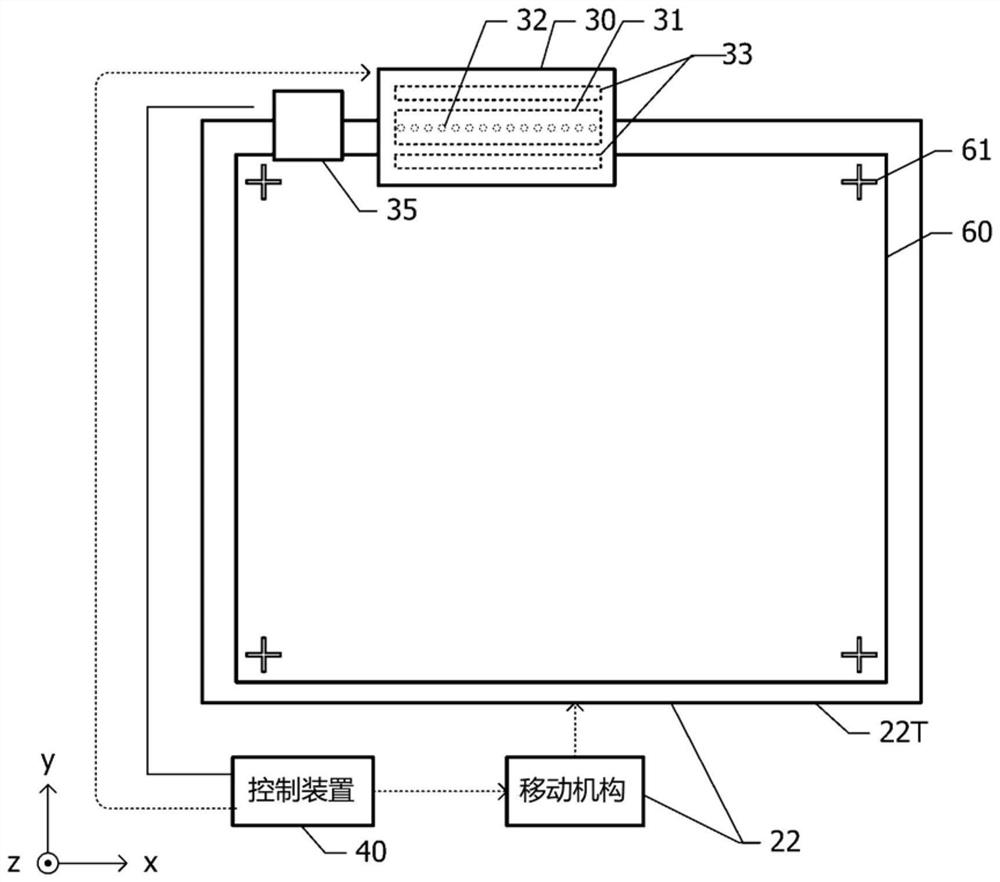

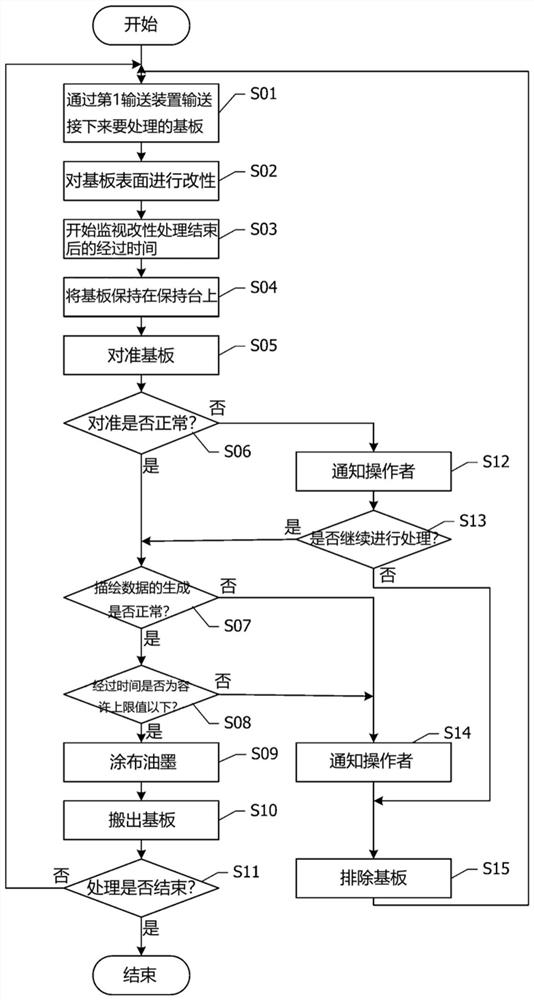

[0027] refer to Figure 1 ~ Figure 4 , an ink application device based on an embodiment will be described.

[0028] figure 1 It is a schematic diagram of the ink application apparatus based on this Example. The substrate 60 is placed on the rollers of the first conveying device 51 composed of a plurality of rollers, and conveyed from the storage position to the intermediate position. The surface modifying device 10 is disposed above the first conveying device 51 . The surface modifying device 10 includes, for example, an ultraviolet lamp that irradiates ultraviolet rays to the surface of the substrate 60 conveyed by the first conveying device 51 . The ultraviolet rays have a long elongated cross-section in the direction perpendicular to the conveying direction of the first conveying device 51 , and can irradiate the entire surface of the substrate 60 being conveyed with ultraviolet rays.

[0029] The second transport device 52 transports the substrate 60 transported to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com