Method for winding tape

A technology of reel and adhesive tape, applied in the field of tape winding, to achieve the effect of suppressing product defects and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings.

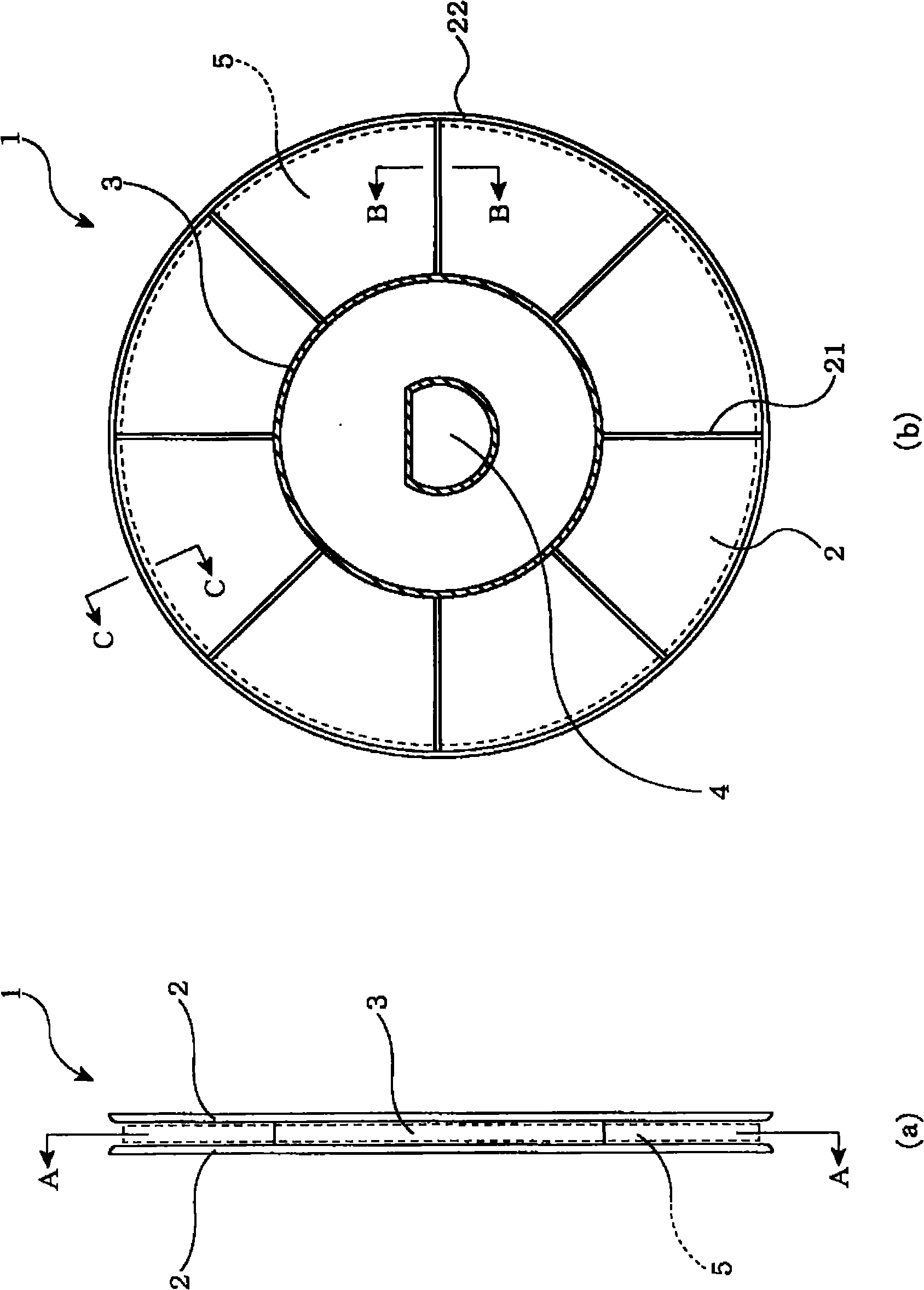

[0023] in addition, figure 1 It is a schematic explanatory drawing which shows the reel used for the tape winding method of this embodiment. figure 1 (a) is the front view, figure 1 (b) is figure 1 (a) A-A sectional view.

[0024] figure 1 The illustrated reel 1 includes a cylindrical winding portion 3 and a pair of side plate portions 2 , 2 mounted oppositely across the winding portion 3 in parallel or substantially in parallel. In addition, substantially in the center of the reel 1, a shaft hole 4 in the shape of a D hole is penetratingly provided. By inserting a winding shaft of a winding device (not shown) into the shaft hole 4, the reel 1 is attached to the reel. On the winding device, it rotates with the drive of the winding shaft.

[0025] The reel 1 of this structure is used to cut the film material coated with the adhesive layer into a nar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com