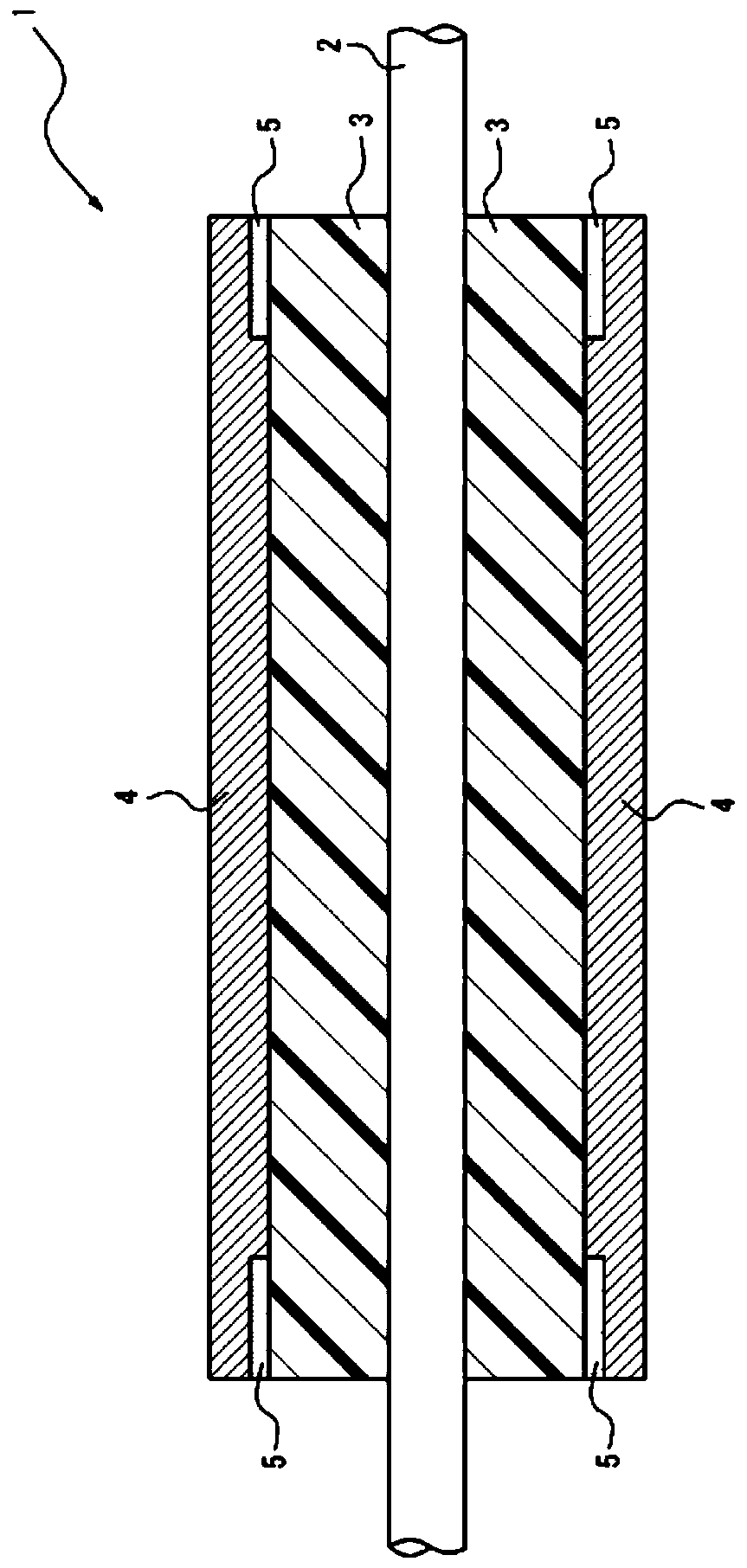

Development roller and development roller manufacturing method

A manufacturing method and technology for developing rollers, which are applied in chemical instruments and methods, electrical recording processes using charge patterns, and equipment using electrical recording processes applying charge patterns, etc., can solve the problems of peeling off of developing rollers, wear of the ends of developing rollers, etc. , to achieve the effects of suppressing adhesion, efficient manufacturing, and ensuring interlayer adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

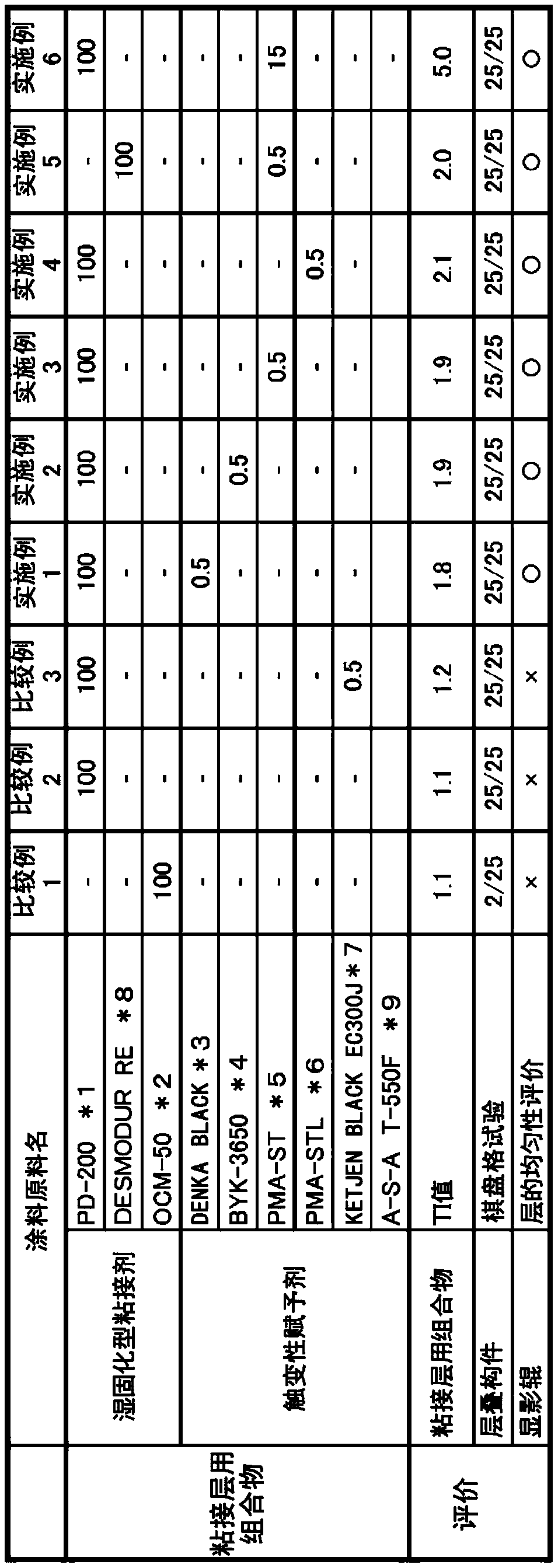

Embodiment 1~6、 comparative example 1~3

[0154] A developing roller was produced according to the method described below.

[0155]

[0156] In a three-necked flask, Excenol 5030 (manufacturer: Asahi Glass Co., Ltd.) and TDI (manufacturer: Mitsui Chemicals, Inc.) were mixed so that the isocyanate index (number of moles of NCO / number of moles of OH) became 4.5, and a mantle heater was used It heated at liquid temperature 70 degreeC for 2 hours. The disappearance of the polyol was confirmed by the hydroxyl value method, and prepolymerized TDI was prepared.

[0157]

[0158]Compounding 2000 parts by mass of SANNIX FA-951 (manufacturer: Sanyo Chemical Industry Co., Ltd.), 5000 parts by mass of KURARAY POLYOL F-510 (manufacturer: Kuraray Co., Ltd.) of polyol, 2000 parts by mass of Polyol KURARAY POLYOL F-1010 (manufacturer: Kuraray Co., Ltd.), 650 parts by mass of LIGHT ESTER HOA (manufacturer: Kyoeisha Chemical Co., Ltd.) as acrylate having a hydroxyl group, 10 parts by mass as carbamic acid Neostann U-100 (manufact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thixotropic index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com