High-barrier straw-free type packaging cup

A straw-type, high-barrier technology, applied in packaging, transportation, packaging, closing, etc., can solve problems such as shedding, non-existence, and affecting the production efficiency of filling lines, so as to extend shelf life, ensure freshness and safety , Optimize the effect of drinking experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

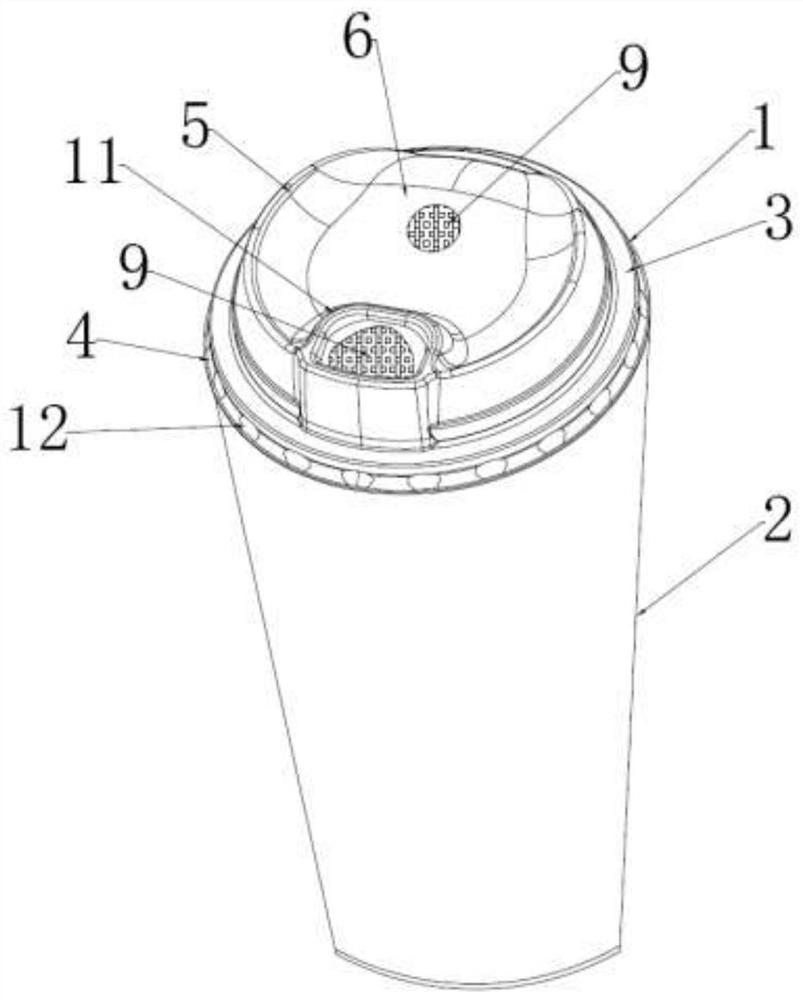

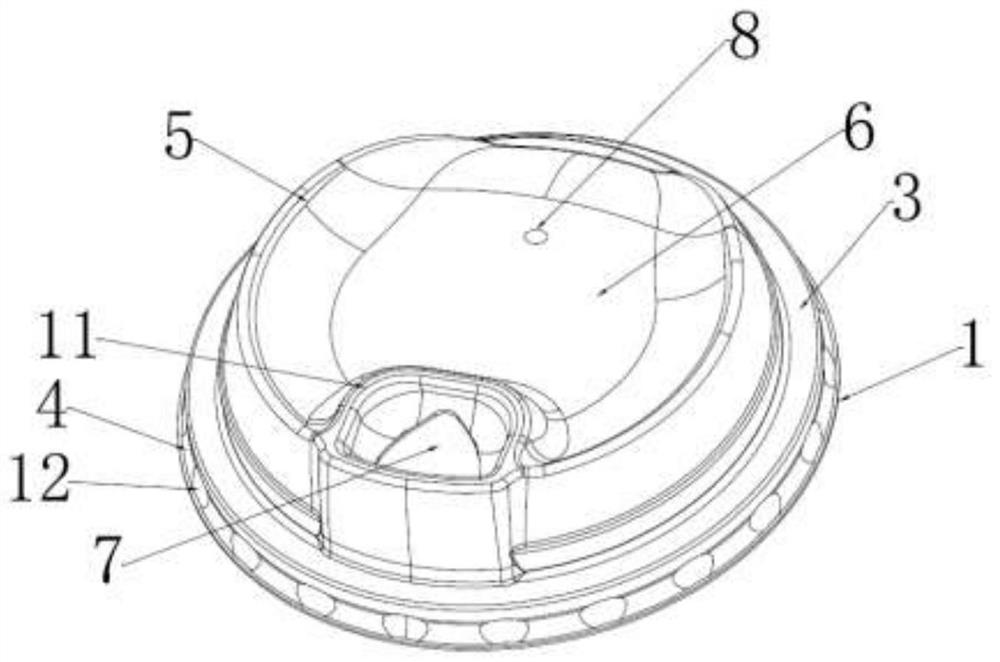

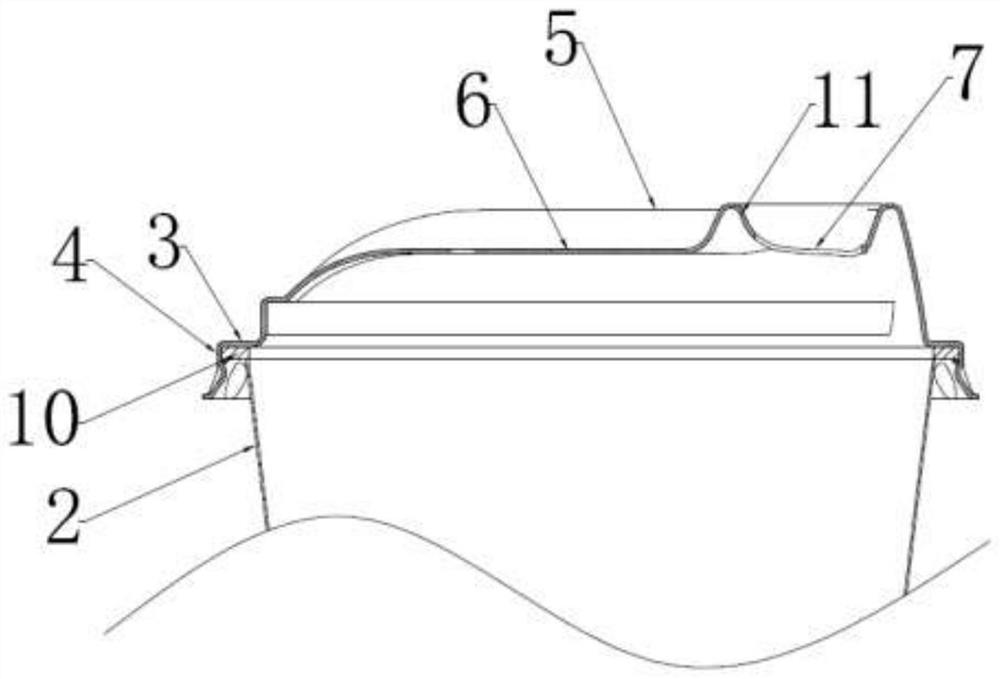

[0031] Embodiment 1, the cover body 1 of the present invention is connected with the cup body 2 by sealing welding, such as image 3 shown.

[0032] The peripheral ring of the cup mouth of the cup body 2 is provided with a cup rim 10, the cup rim 10 is matched with the cover rim 3, and is fixedly connected by welding the skirt 4, which is welded with the cup body 2, and the drinking hole 7 and The vent hole 8 is covered with a heat shrinkable film on the outside of the cover 1 sealed by the barrier film 9. After filling the content through the drinking hole 7, the drinking hole 7 and the vent hole on the protrusion 6 are sealed with a barrier film 9 8. A layer of transparent heat-shrinkable film is placed on the outside of the cover body 1 to cover it, which is conducive to transportation and storage, and avoids possible pollution before transportation, storage and drinking; when drinking, remove the heat-shrinkable film and barrier The film 9 can directly drink the content t...

Embodiment 2

[0033] Embodiment 2, the lid body 1 of the present invention is fastened with the cup body 2, as Figure 4 shown.

[0034] The peripheral ring of the cup mouth of the cup body 2 is provided with a cup rim 10, the cup rim 10 is matched with the lid rim 3, and the skirt 4 is provided with evenly distributed hemispherical protrusions 12 protruding inwardly. , the cover body 1 is fastened to the cup edge 10 of the cup body 2 through the hemispherical protrusion 12 on the skirt 4. This connection method is stable and can be used for packaging of ready-to-pack contents for sale, such as freshly squeezed Juice, milk tea, etc.

[0035] In the above two methods, when you need to drink the contents, you only need to remove the barrier film of the drinking hole and the vent hole. If there is a heat shrinkable film, remove the shrinkable film first, wrap the lip edge and the connected part of the convex edge through the lips, and pass You can drink from the drinking hole without a straw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com