Cloth flattening and processing equipment

A processing equipment and cloth leveling technology, applied in the direction of thin material processing, heating/cooling fabrics, textiles and papermaking, etc., can solve the problems of affecting the service life of transport parts, affecting the working efficiency of equipment, increasing energy consumption of equipment, etc., to prevent movement The effects of blocking, improving efficiency, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

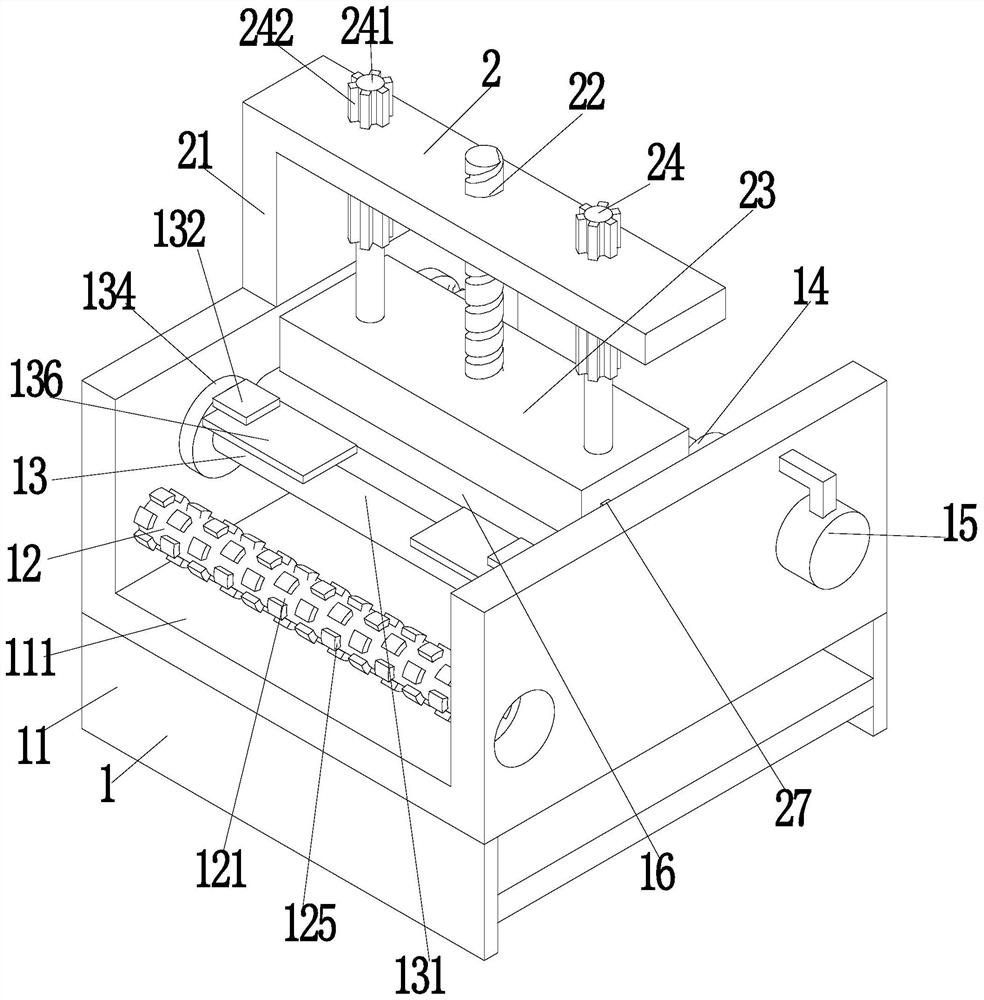

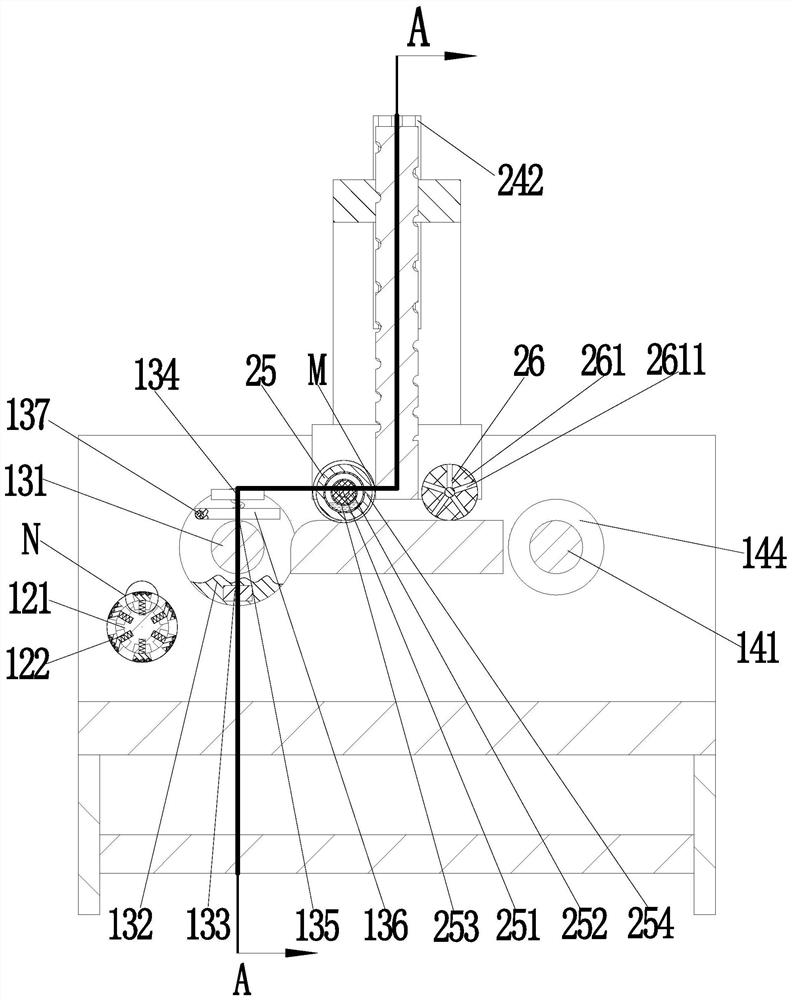

[0030] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0031] refer to figure 1 , a fabric leveling processing equipment, comprising a transport device 1 and a leveling device 2, the upper end of the transport device 1 is fixedly installed with a leveling device 2; wherein:

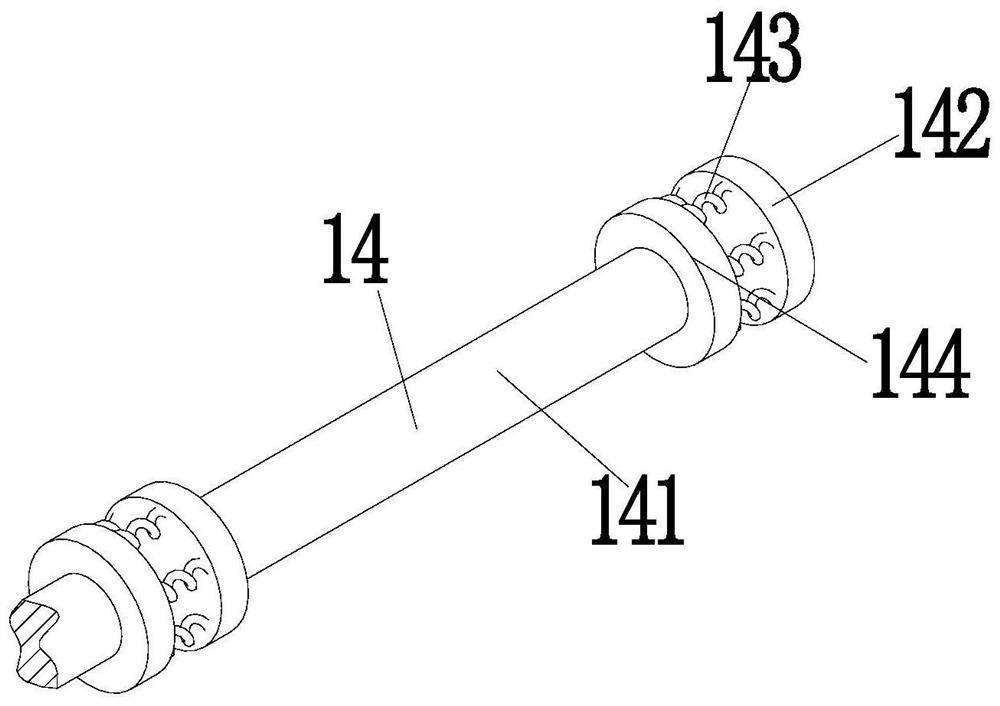

[0032] read on figure 1 , the transportation device 1 includes a workbench 11, a positioning roller 12, a guide roller 13, a conveying roller 14, a motor one 15 and a support plate 16, and the middle part of the upper side of the workbench 11 is provided with a rectangular long groove 111, and the rectangular long groove 111 Positioning roller 12 is rotatably connected to the inner left side, guide roller 13 is rotatably connected to the right side of locating roller 12 in the rectangular long groove 111, and conveying roller 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com