Fabricated structure matched with special-shaped steel pipe column and construction method of fabricated structure

A special-shaped steel pipe and assembled technology, which is applied in the fields of basic structure engineering, building structure, and building material processing, etc., can solve the problems of lack of mature technology and restrict the construction period of assembled structures, and achieve shortened construction period and good application Value and scientific research benefits, simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

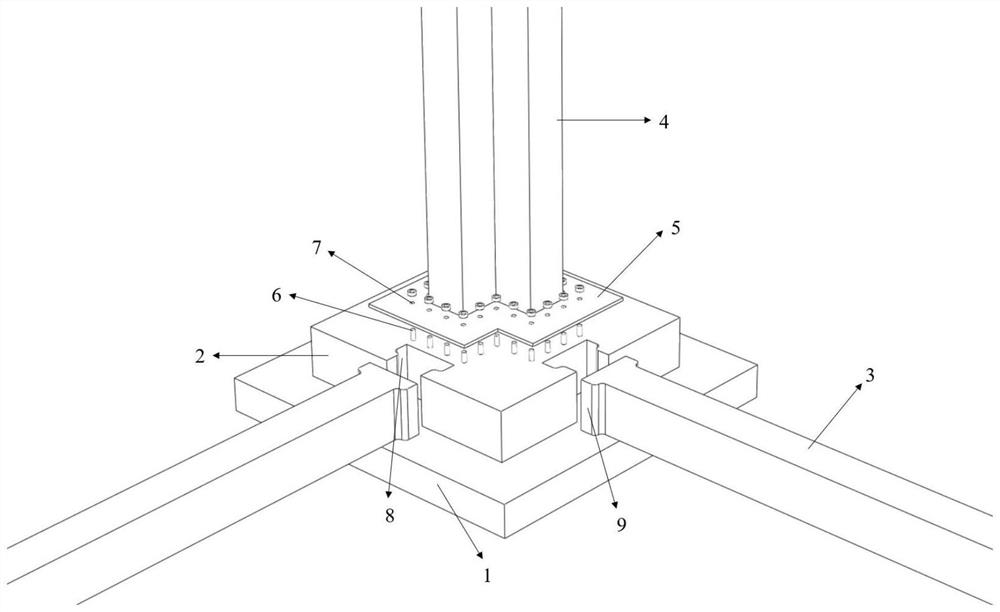

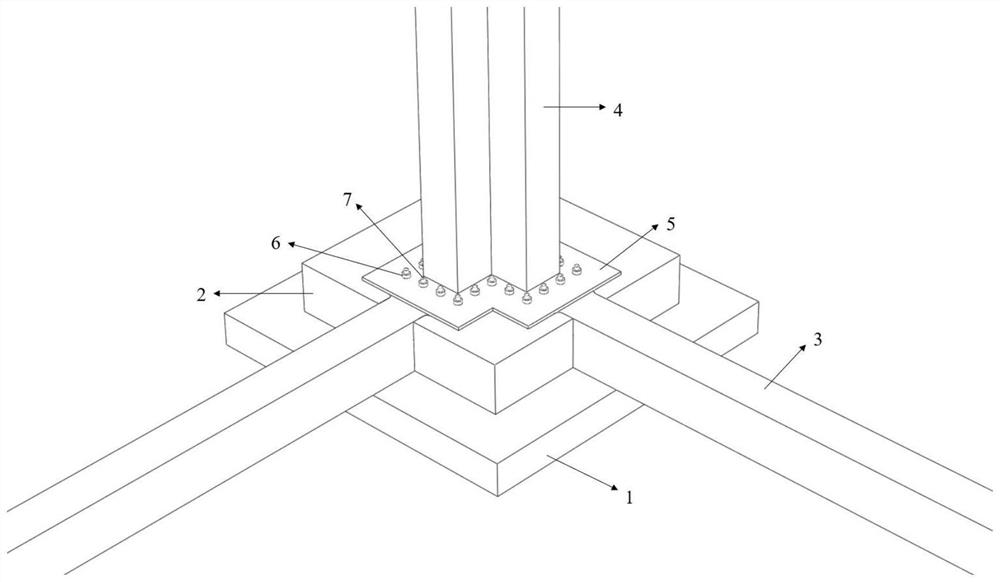

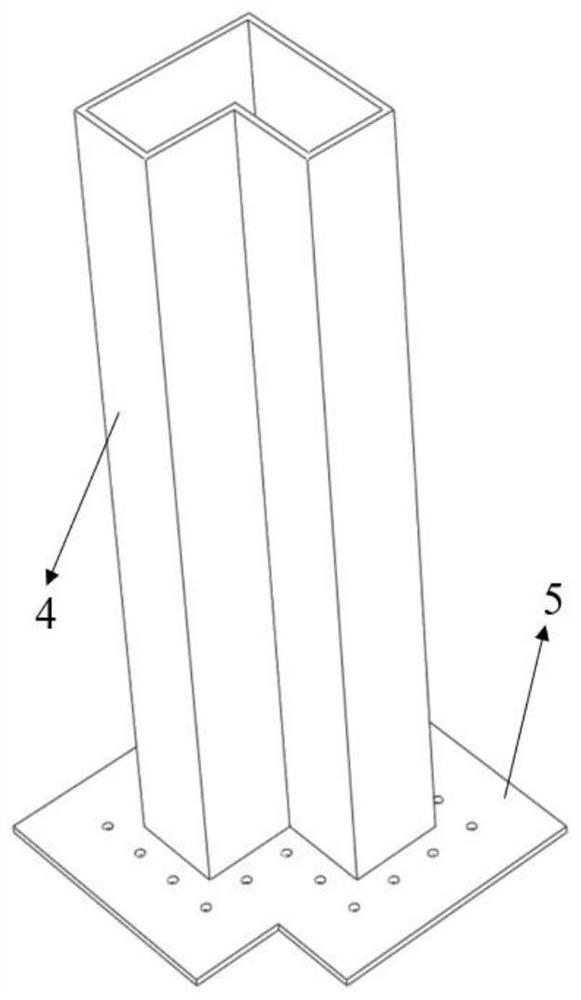

[0043] Embodiment 1: as Figure 1-Figure 4 As shown, an assembled structure adapted to special-shaped steel pipe columns, including a first prefabricated slab 1, a second prefabricated slab 2, a foundation beam 3 and a special-shaped steel pipe column 4; the second prefabricated slab is fixed above the first prefabricated slab 1 2. The side wall of the second prefabricated panel 2 is provided with a mortise 8 matching the special-shaped steel pipe column 4, and both ends of the concrete foundation beam 3 are provided with a mortise 9 matching the mortise 8. The tenon 9 is snapped into the tenon groove 8 to connect the concrete foundation beam 3 with the second prefabricated slab 2 by mortise and tenon, the upper part of the second prefabricated slab 2 is pre-embedded with several bolt rods 6, and the lower end of the special-shaped steel pipe column 4 is welded with the outer reinforcing ring plate 5, so The outer reinforcing ring plate 5 is used to press the tenon 9 on the co...

Embodiment 2

[0048] Example 2, such as Figure 1-4 As shown, an assembled structure adapted to special-shaped steel pipe columns, including a first prefabricated slab 1, a second prefabricated slab 2, a foundation beam 3 and a special-shaped steel pipe column 4; the second prefabricated slab is fixed above the first prefabricated slab 1 2. The side wall of the second prefabricated panel 2 is provided with a mortise 8 matching the special-shaped steel pipe column 4, and both ends of the concrete foundation beam 3 are provided with a mortise 9 matching the mortise 8. The tenon 9 is snapped into the tenon groove 8 to connect the concrete foundation beam 3 with the second prefabricated slab 2 by mortise and tenon, the upper part of the second prefabricated slab 2 is pre-embedded with several bolt rods 6, and the lower end of the special-shaped steel pipe column 4 is welded with the outer reinforcing ring plate 5, so The outer reinforcing ring plate 5 is used to press the tenon 9 on the concret...

Embodiment 3

[0053] Example 3, such as Figure 1-4 As shown, an assembled structure suitable for special-shaped steel pipe columns is shown, including a first prefabricated slab 1, a second prefabricated slab 2, a foundation beam 3 and a special-shaped steel pipe column 4; Prefabricated slab 2, the side wall of the second prefabricated slab 2 is provided with a mortise 8 matched with the special-shaped steel pipe column 4, and both ends of the concrete foundation beam 3 are provided with a mortise 9 matching the mortise 8, The mortise 9 snaps into the mortise 8 to connect the concrete foundation beam 3 with the second prefabricated slab 2 mortise and tenon connection, the upper part of the second prefabricated slab 2 is pre-embedded with several bolt rods 6, and the lower end of the special-shaped steel pipe column 4 is welded with an outer reinforcing ring plate 5 , the outer reinforcing ring plate 5 is used to press the tenon 9 on the concrete foundation beam 3, the outer reinforcing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com