Urban highway environment-friendly construction device and construction method

A technology for construction devices and roads, applied in separation methods, chemical instruments and methods, cleaning methods, etc., can solve problems such as low construction efficiency, and achieve the effects of speeding up construction efficiency, convenient operation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

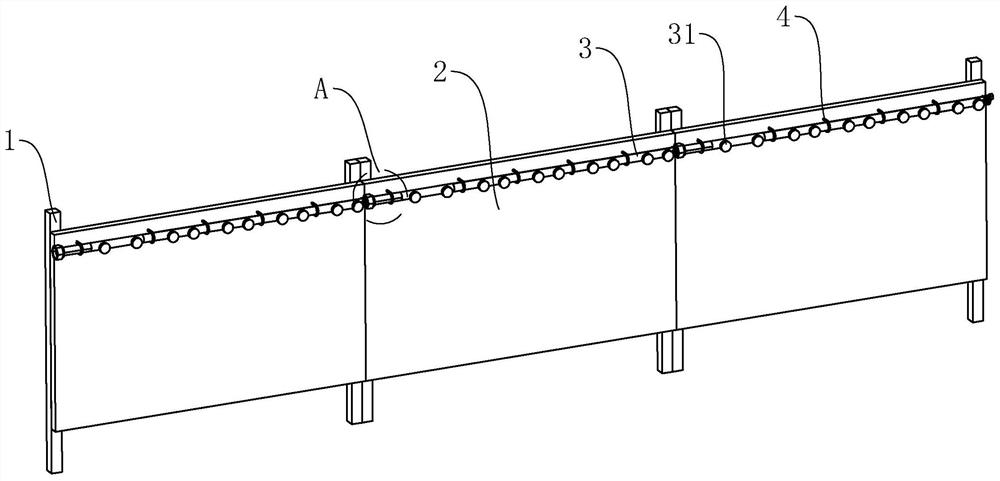

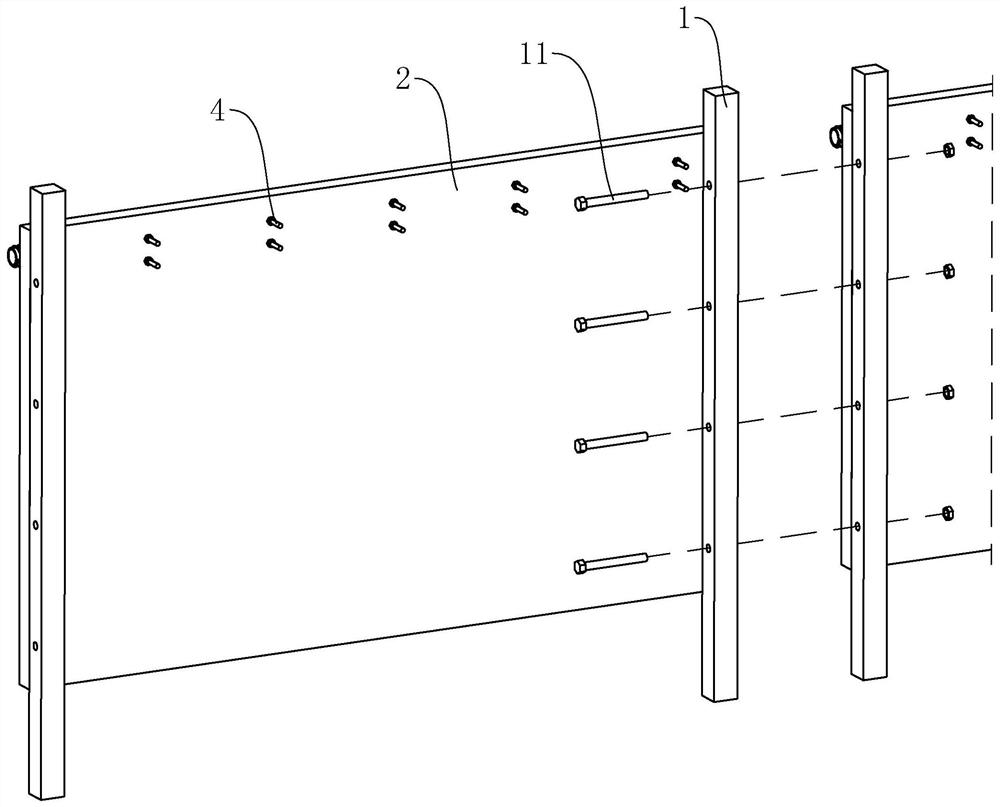

[0047] refer to figure 1 , There are several enclosures in the construction device. The enclosures are located in the highway construction area. The two adjacent enclosures are connected, so that the dust generated during the highway construction process is not easy to spread to the outside world, and the two adjacent enclosures can be removed. open to facilitate the construction and transfer of the enclosure.

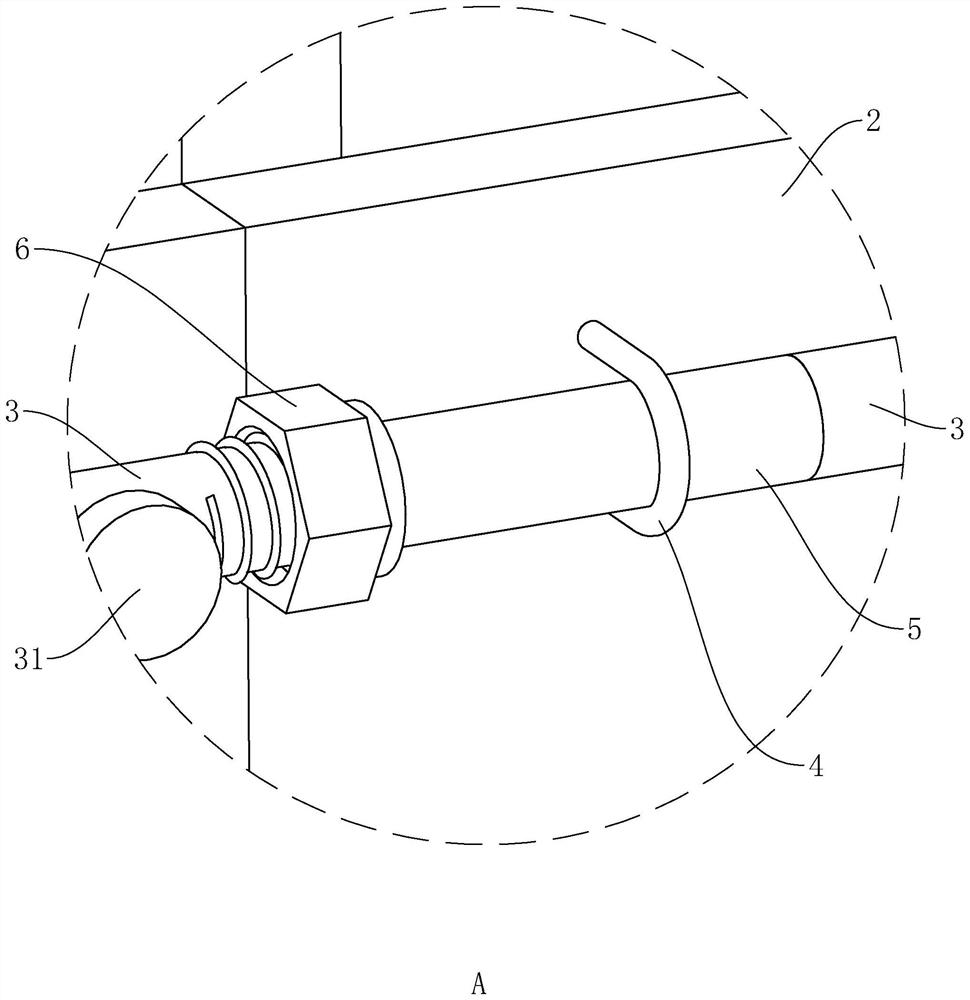

[0048] Among them, refer to figure 1 and figure 2 , the enclosure includes two columns 1 and baffles 2, the column 1 is a vertically placed rectangular column, the two columns 1 are spaced along the horizontal direction, the baffle 2 is a vertically placed flat plate, and the baffle 2 is in the horizontal direction The opposite ends are welded and fixed with the two uprights 1 respectively. The height of the bottom end of the column 1 is lower than the height of the bottom end of the baffle plate 2. The bottom end of the column 1 can be fixed on the ground on both ...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that a telescopic member 7 is provided between the connecting pipe 5 and the conveying pipe 3 .

[0055] refer to Figure 5 , In this embodiment, a support ring 21 is fixed on the side wall of the baffle 2 away from the column 1, and the connecting pipe 5 is slidably connected to the support ring 21 through the support ring 21, so that the connecting pipe 5 can be connected to the baffle 2. Sliding along its own axis. The telescopic element 7 is connected between the conveying pipe 3 and the connecting pipe 5 , so that the connecting pipe 5 can maintain the state of communicating with the conveying pipe 3 when sliding.

[0056] In the process of building the enclosure, due to construction errors or processing errors, it is easy to cause the phenomenon that the distance between the connecting pipe 5 and the conveying pipe 3 in the two adjacent enclosures in the axial direction is too large or too small, which af...

Embodiment 3

[0063] The difference between this embodiment and the second embodiment is that the structure of the telescopic element 7 is different.

[0064] refer to Image 6 In this embodiment, the telescopic member 7 includes a moving pipe 72 and two hoses 71. The moving pipe 72 is located between the conveying pipe 3 and the connecting pipe 5. The axis of the moving pipe 72 is parallel to the axis of the conveying pipe 3. The moving pipe 72 The moving pipe 72 is a hard pipe supported by a PVC material or a metal material, and the moving pipe 72 is inserted into the slip ring 24 and is fixedly connected to the slip ring 24 . Two hoses 71 are sleeved and fixed on both ends of the moving pipe 72 respectively, one of the hoses 71 is sleeved and fixed on the conveying pipe 3 at the end of the hose 71 away from the moving pipe 72 , and the other hose 71 is away from the end of the moving pipe 72 . The sleeve is fixed on the connecting pipe 5 so as to connect the conveying pipe 3 with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com