Device for pumping polyphenyl granule slurry

A technology of slurry and material cylinder, which is applied in the field of construction engineering pumping devices, can solve the problems of low pumping speed, change of slurry bulk density, and short service life of screws, etc., and achieve high pumping efficiency, improved efficiency, and improved work efficiency and the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

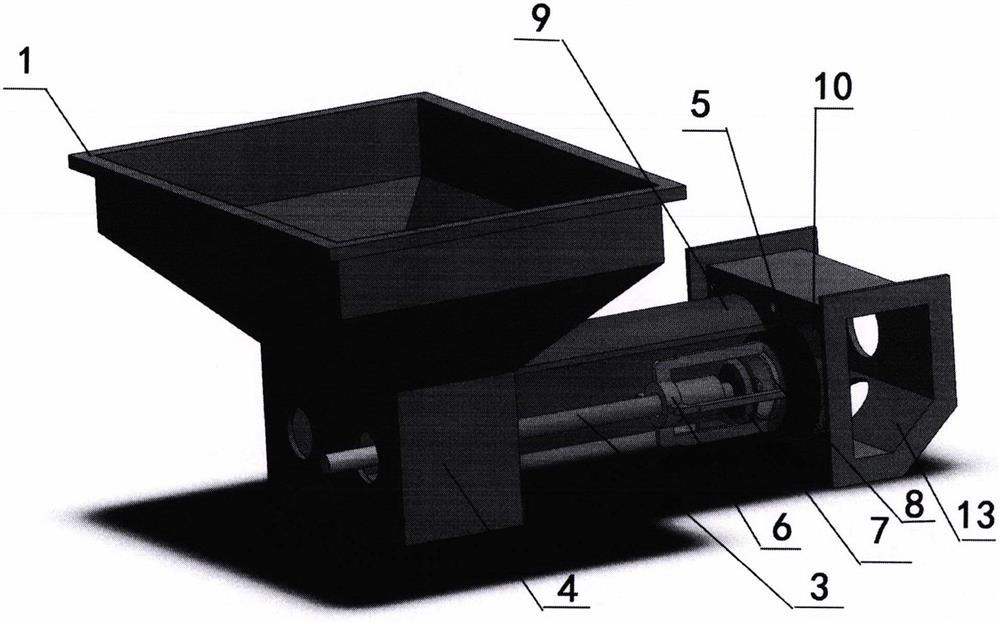

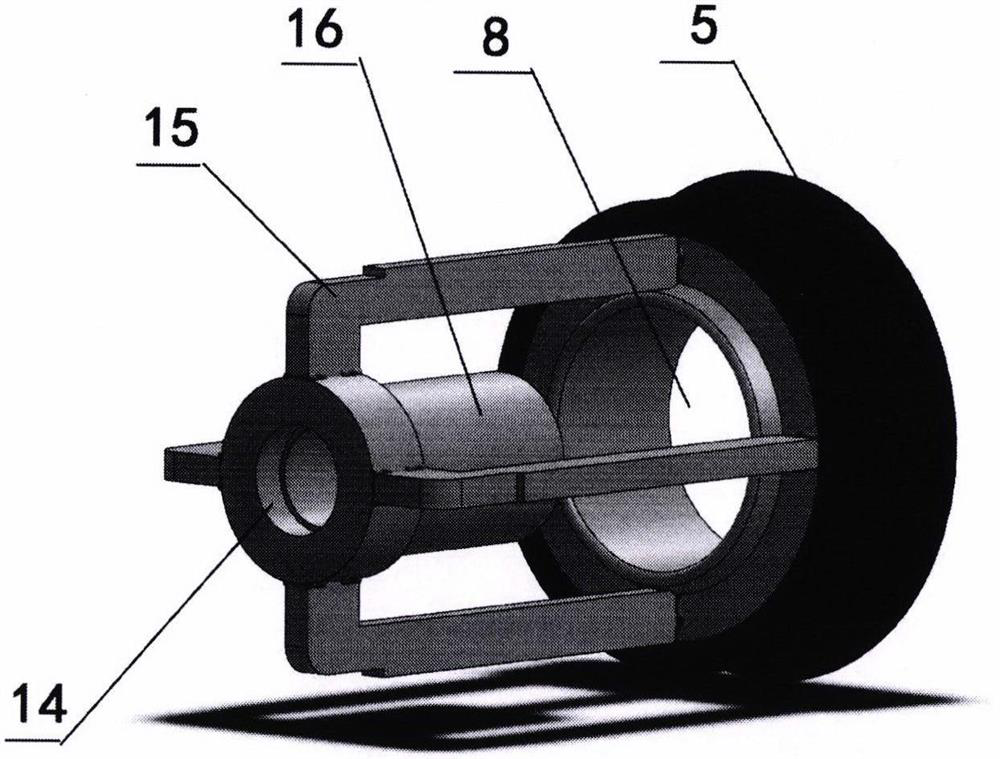

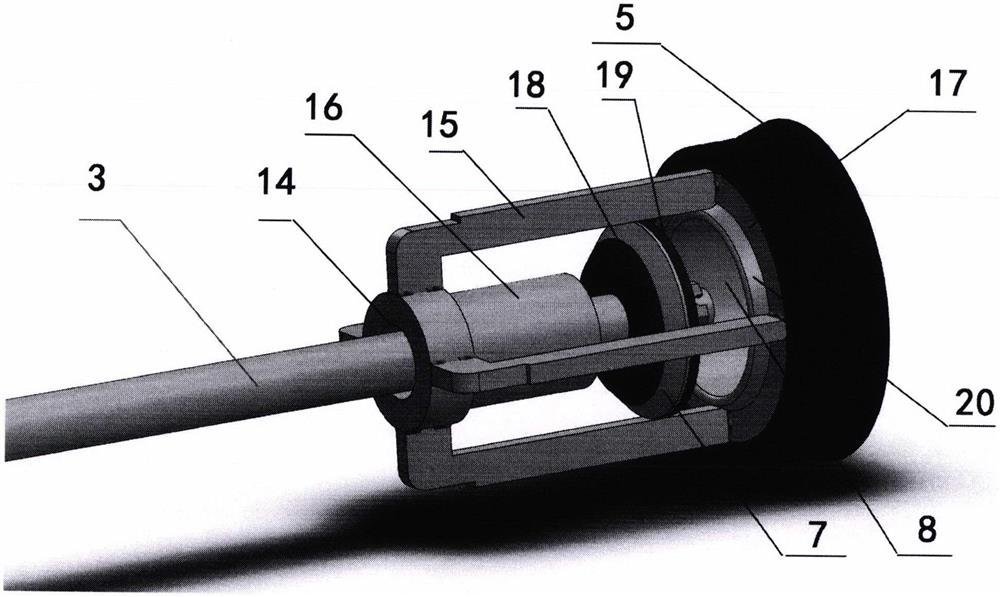

[0037] see figure 1 , 4 , 5, the device that polyphenylene particle slurry pumping of the present invention comprises: hopper 1, hydraulic cylinder (not shown in the figure), hydraulic cylinder shaft 3 (also claiming push rod 3), feeding bin 4, piston body 5. Piston tailpipe 6, feed port cover 7, feed port 8, feed cylinder 9, discharge port 10, discharge port cover 11, conveying pipe connection port 12, discharge bin 13. Among them, the hydraulic cylinder 2, the discharge port cover 11, the delivery pipe connection port 12, and the discharge bin 13 are in the figure 1 not seen in , see Figure 4 or Figure 5 . The hopper 1 is set above the feed bin 4 and communicates with the feed bin 4. Two through holes are opened on the left side wall of the feed bin 4 for the shaft of the hydraulic cylinder to pass through. The hydraulic cylinder 2 is fixedly installed on the left side of the feed bin 4. on the wall. The number of hydraulic cylinders can be selected as one or more a...

specific Embodiment approach 2

[0048] Embodiment 2 according to the present invention differs from Embodiment 1 above in that the discharge port covers are different, and the rest of the structures are the same.

[0049] see Figure 8 , in the second specific embodiment, the second discharge port cover 31 can reciprocate left and right along the axial direction of the discharge port cover shaft 27, when the second discharge port cover 31 presses the discharge port 10, the second discharge port The cover 31 can close the discharge port 10, and the second discharge port cover 31 can be a multi-layer structure, wherein the side close to the discharge port 10 is set as an elastic sealing layer. The second discharge port cover 31 is supported by the discharge port cover shaft 27. The discharge port cover shaft 27 is installed inside the discharge port cover guide block 30. The reciprocating hole, the parts that reduce the friction between the hole and the discharge port cover shaft 27 can be arranged, such as s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com