High-energy-efficiency air source heat pump during partial load operation

An air source heat pump, part load technology, used in heat pumps, lighting and heating equipment, compressors with reversible cycles, etc., can solve problems such as low energy efficiency and idle fin heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

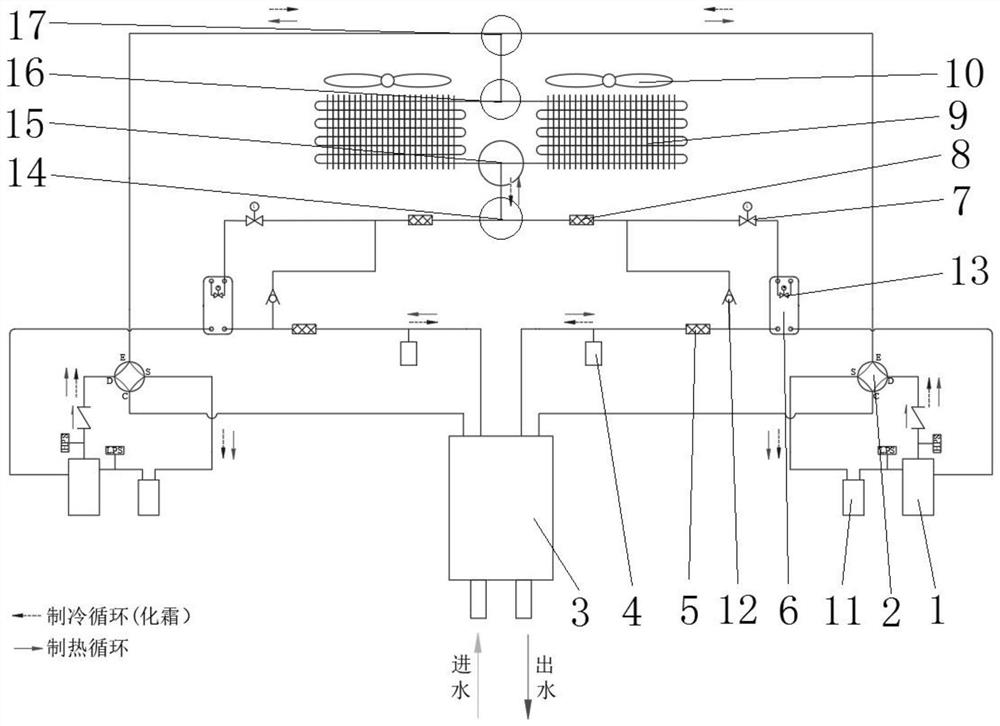

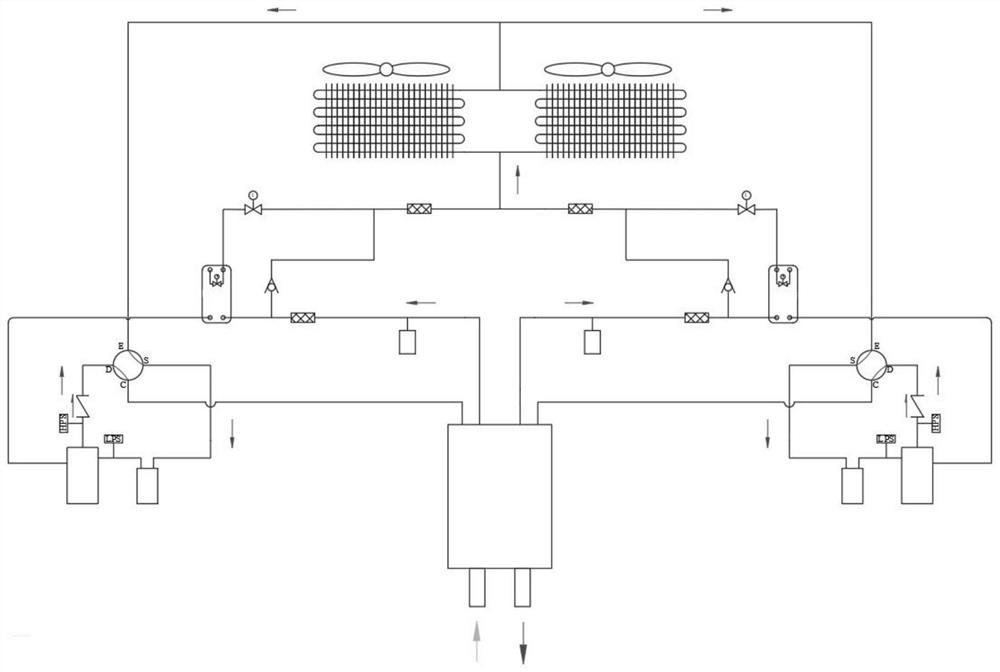

[0019] Such as Figure 1-2 As shown, a high-energy-efficiency air source heat pump in part-load operation includes two subsystems arranged symmetrically, and the two subsystems share a shell-and-tube heat exchanger 3, and each of the subsystems is connected to two Fin heat exchanger 9, the inlet front ends of the two fin heat exchangers 9 are connected in parallel through the first Y-type three-way valve 14 and the second Y-type three-way valve 15, and the two fin heat exchangers 9 The rear end of the outlet is connected in parallel through the third Y-type three-way valve 16 and the fourth Y-type three-way valve 17. The subsystem includes a compressor 1, a four-way valve 2, a balance tank 4, a two-way dry filter 5, an economizer 6 and gas-liquid separator 11, the compressor 1, the four-way valve 2, the shell-and-tube heat exchanger 3, the balance tank 4, the two-way dry filter 5 and the economizer 6 are connected in sequence , the pipeline between the economizer 6 and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com