Method for measuring aperture by using probe

A technology for measuring aperture and aperture, applied in the field of mechanical processing, can solve problems affecting measurement accuracy and measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for measuring an aperture using a probe, comprising the steps of:

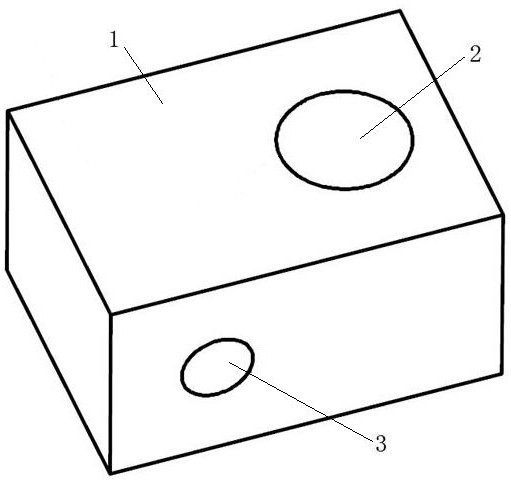

[0027] a. Classify the holes to be tested in the test piece 1, divide the holes whose axes are distributed in the vertical direction and its surrounding areas into type A holes, and divide the holes whose axes are distributed in the horizontal direction and its surrounding areas into type B holes;

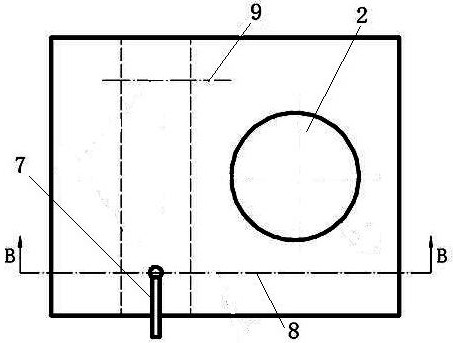

[0028] b. For type A hole measurement, the first probe 4 is called by the machine tool to measure the hole diameters φ1 and φ2 in two planes perpendicular to the axis of the hole in turn, calculate the difference Δ between φ1 and φ2, and compare the Δ value with the tolerance zone of the hole diameter Obtain the diameter value of type A hole;

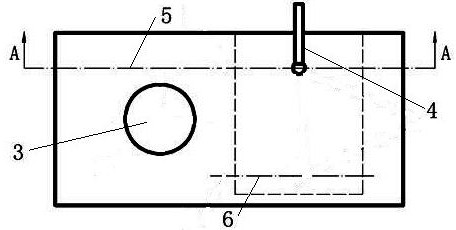

[0029] c. For type B hole measurement, set the measuring point of the second probe 7 away from the lowest point of the inner wall of the hole, call the second probe 7 through the machine tool to measure the hole diameters φ3 and φ4 in two planes perpendicular...

Embodiment 2

[0031] A method for measuring an aperture using a probe, comprising the steps of:

[0032] a. Classify the holes to be tested in the test piece 1, divide the holes whose axes are distributed in the vertical direction and its surrounding areas into type A holes, and divide the holes whose axes are distributed in the horizontal direction and its surrounding areas into type B holes;

[0033] b. For type A hole measurement, the first probe 4 is called by the machine tool to measure the hole diameters φ1 and φ2 in two planes perpendicular to the axis of the hole in turn, calculate the difference Δ between φ1 and φ2, and compare the Δ value with the tolerance zone of the hole diameter Obtain the diameter value of type A hole;

[0034] c. For type B hole measurement, set the measuring point of the second probe 7 away from the lowest point of the inner wall of the hole, call the second probe 7 through the machine tool to measure the hole diameters φ3 and φ4 in two planes perpendicular...

Embodiment 3

[0037] A method for measuring an aperture using a probe, comprising the steps of:

[0038] a. Classify the holes to be tested in the test piece 1, divide the holes whose axes are distributed in the vertical direction and its surrounding areas into type A holes, and divide the holes whose axes are distributed in the horizontal direction and its surrounding areas into type B holes;

[0039] b. For type A hole measurement, the first probe 4 is called by the machine tool to measure the hole diameters φ1 and φ2 in two planes perpendicular to the axis of the hole in turn, calculate the difference Δ between φ1 and φ2, and compare the Δ value with the tolerance zone of the hole diameter Obtain the diameter value of type A hole;

[0040]c. For type B hole measurement, set the measuring point of the second probe 7 away from the lowest point of the inner wall of the hole, call the second probe 7 through the machine tool to measure the hole diameters φ3 and φ4 in two planes perpendicular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com