A Method for Preparation of Ceramic Bone Scaffold by Introducing Continuous Liquid Phase in Selective Laser Sintering

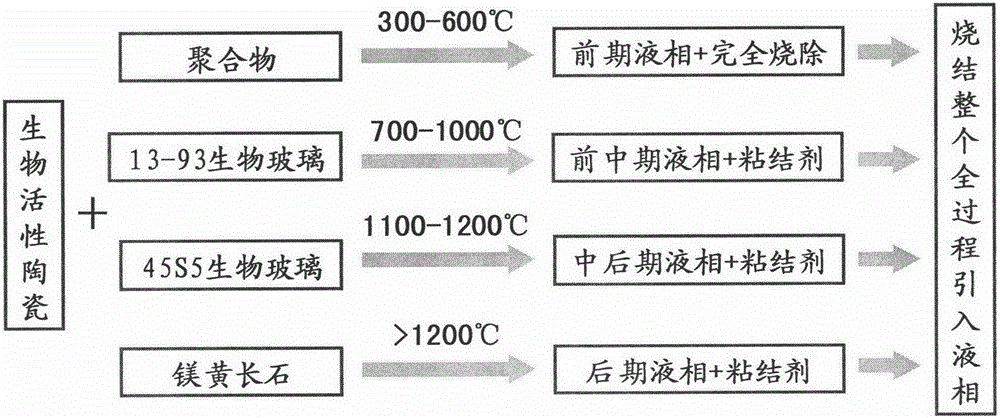

A technology of laser selective sintering and bone scaffolding, which is applied in medical science, prosthesis and other directions, can solve the problem of impossible solid-phase sintering, and achieve the effect of improving sintering performance and promoting densification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be further described below in conjunction with an embodiment, but the content of the present invention is not limited thereto.

[0024] 1) Add 1% poly-left-lactic acid (PLLA), 4% 1393 glass, 12% 45S5 glass, and 3% feldspar powder to the bioceramic β-TCP powder by weight, and mix evenly by mechanical mixing , to prepare β-TCP mixed powder with 20% mass fraction of additives.

[0025] 2) Using the self-developed laser selective sintering machine, the laser is under the control of the computer, according to the interface contour information, the prepared powder is selected for sintering, and the next layer is sintered after one layer is completed, and finally prepared. Porous ceramic artificial bone scaffold.

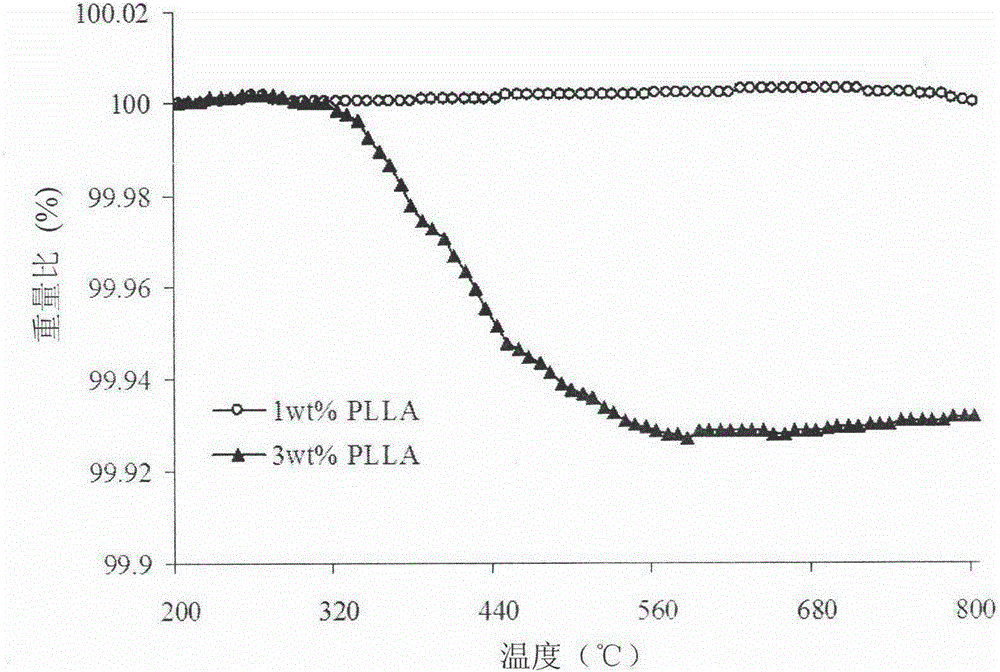

[0026] 3) The mass loss (TGA) test of the prepared ceramic stent was found. The added PLLA (1%) can completely oxidize and disappear ( figure 2 shown), thereby avoiding the adverse effects of polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com