A portable processing machine tool for mechanical processing

A technology of mechanical processing and processing machine tools, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc. It can solve the problems of unable to quickly adjust the falling distance, unable to clean the cutting knife, and accelerate damage to the cutting knife, so as to avoid broken The effect of chip residue, easy processing, and flatness assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

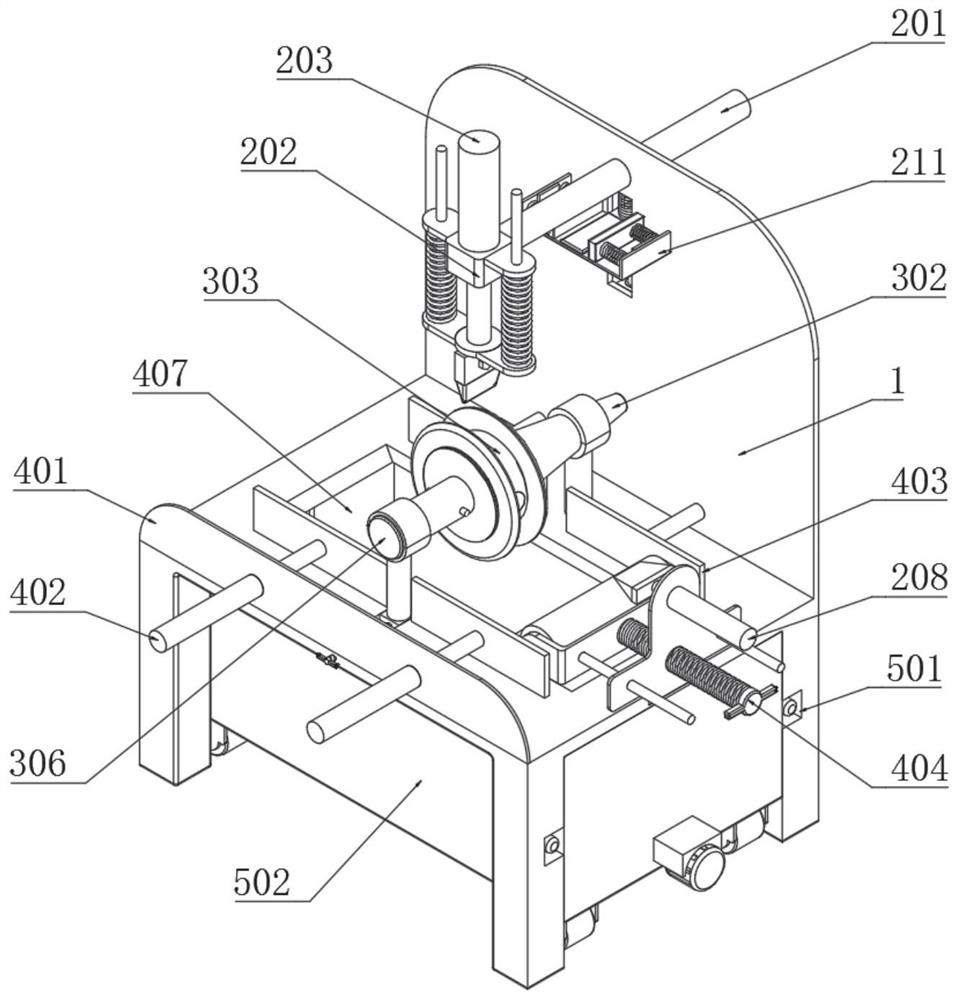

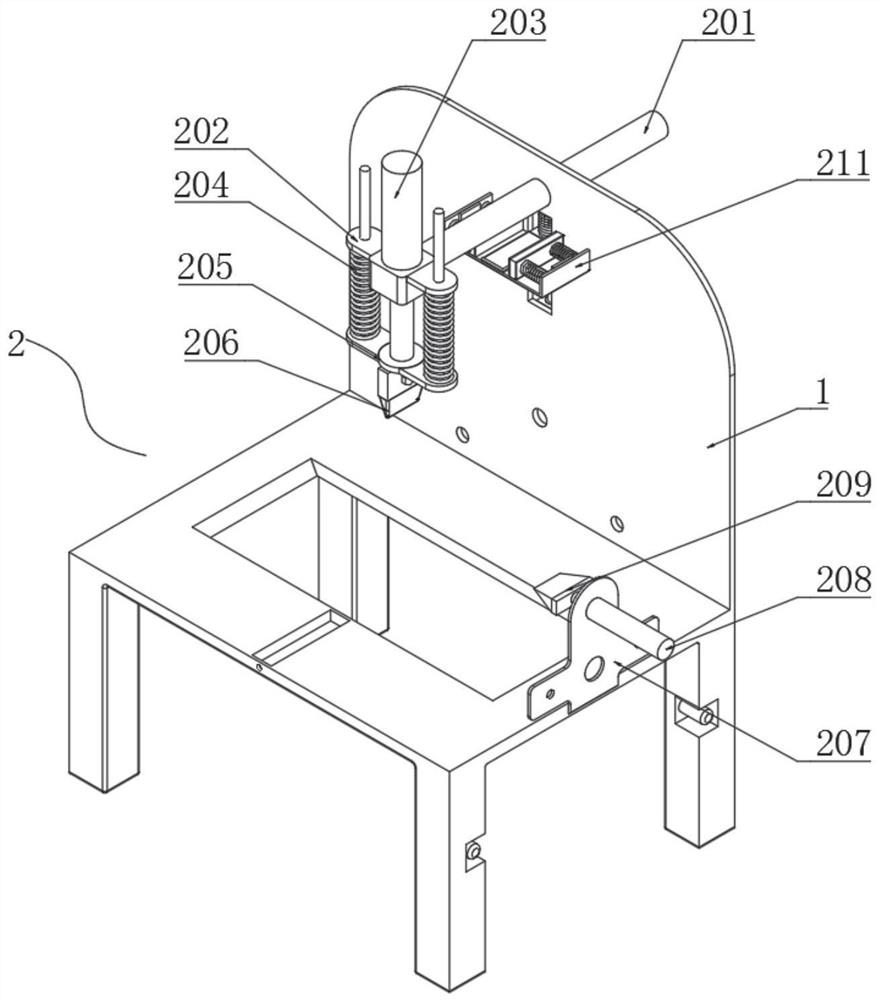

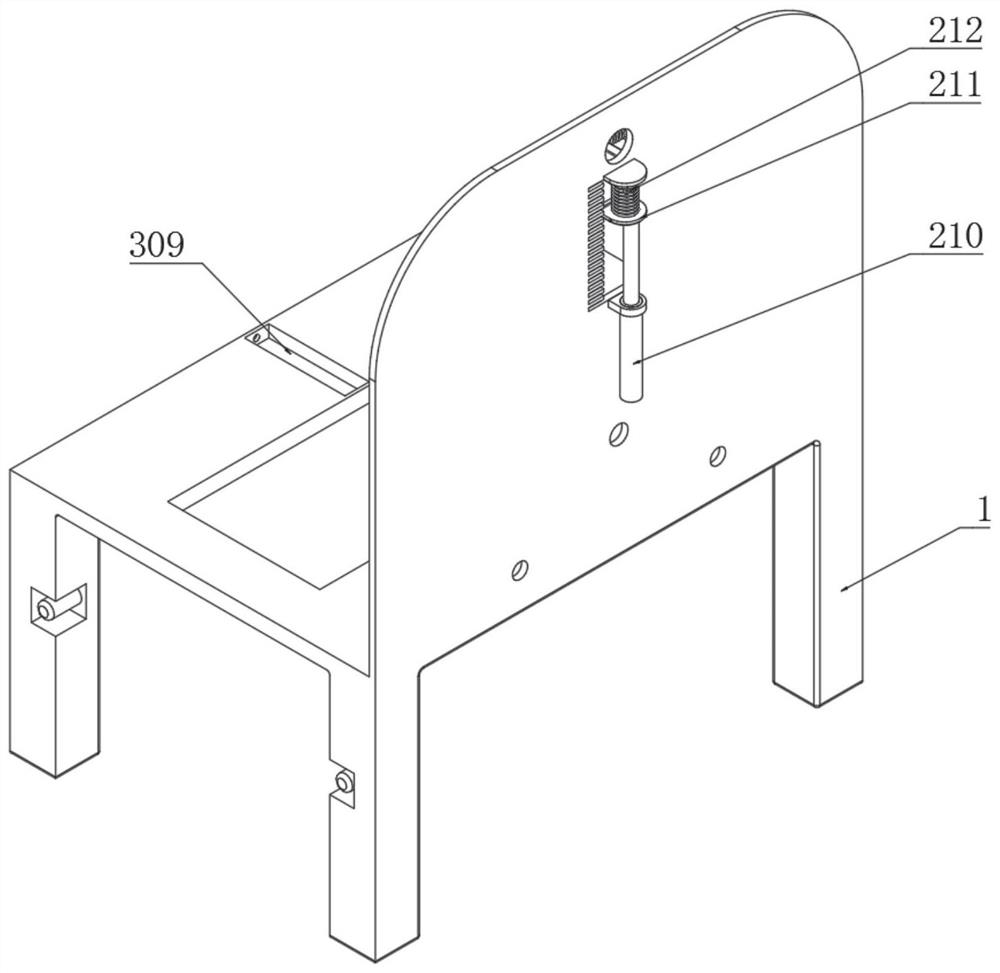

[0043] Example: as Figure 1-9 As shown, the present invention provides a technical solution, a convenient machining machine tool for machining, comprising a fixed support frame 1, a cutting assembly 2 is installed on one side of the fixed support frame 1, and the cutting assembly 2 includes a cutting hydraulic cylinder 201, a downward pressure Frame 202, lower piezoelectric push rod 203, lower pressure spring 204, fixed connection plate 205, cutting knife 206, fixed installation plate 207, push electric push rod 208, correction knife 209, ascending electric push rod 210, limit sliding plate 211 , stabilizing spring 212, protective spring 213, adsorption electromagnet 214, fixed protective box 215, cleaning cotton 216 and contact detector 217;

[0044] A cutting hydraulic cylinder 201 runs through one end of the fixed support frame 1 , and a lower pressure frame 202 is fixedly connected to one end of the cutting hydraulic cylinder 201 away from the fixed support frame 1 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com