Intelligent industrial automatic control instrument system and control method thereof

An instrument system and control method technology, applied in the direction of instruments, force/torque/power measuring instruments, measuring devices, etc., can solve the problems of difficult to complete the adjustment work, difficult to control the preset value, etc., to achieve the use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

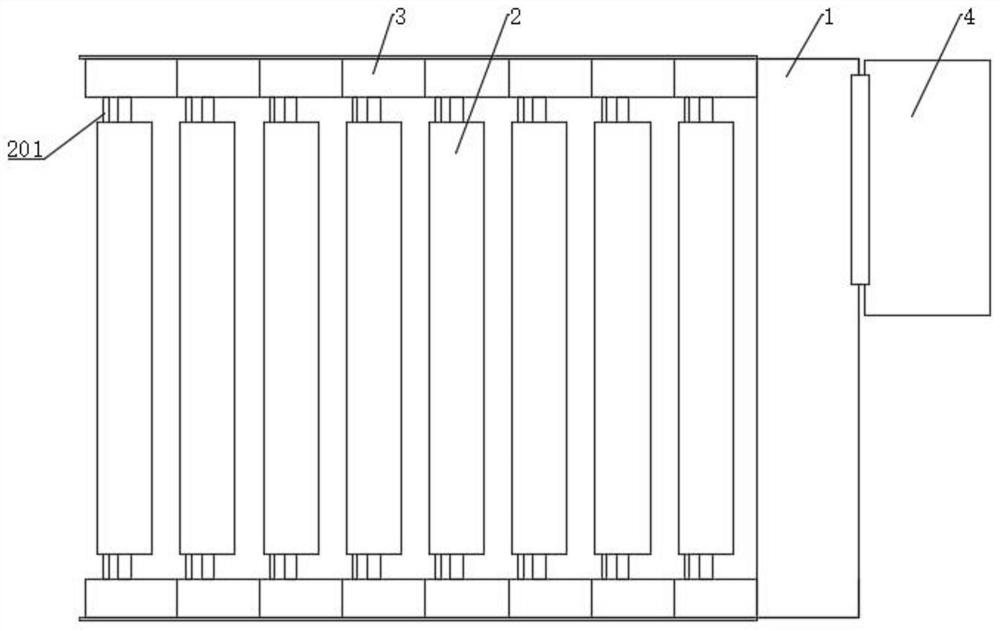

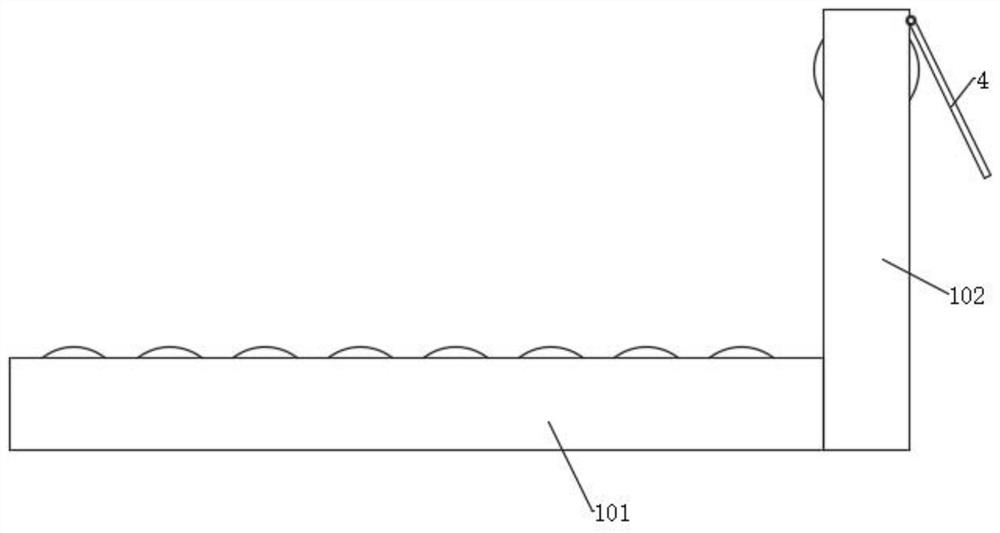

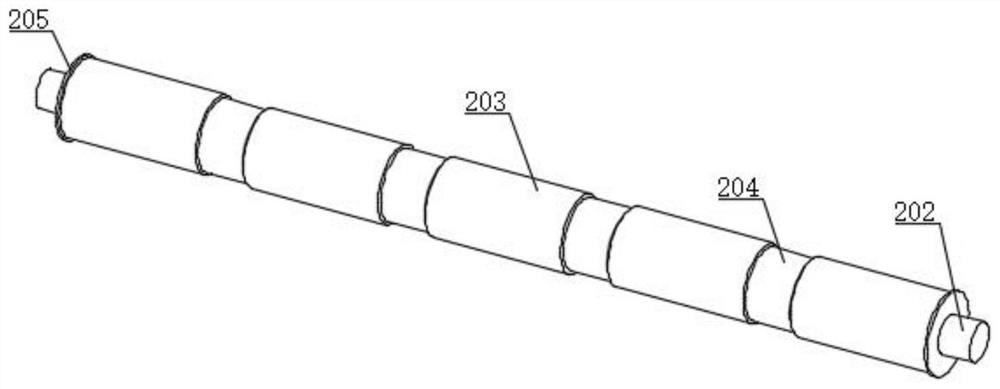

[0036] Such as Figure 1-5 As shown, the embodiment of the present invention provides an intelligent industrial automatic control instrument system, including a transmission frame 1, two rows of roller shaft mounting seats 3 are symmetrically arranged on the inner side of the transmission frame 1, and the roller shaft mounting seats 3 correspond to each other A power roller 2 is connected between the two corresponding roller shaft mounts 3, and a pressure detection ring 204 is arranged on the side of the power roller 2, and the pressure detection ring 204 detects the centrifugal force received by itself, its own gravity, The impact force and bearing capacity received, the annular structure can detect the force received by the power roller 2 for a week, the roller shaft mounting seat 3 is slidingly connected to the transmission frame 1, and the roller shaft mounting seat 3 and the transmission frame 1 are arranged There is a mechanism for adjusting the sliding of the roller sha...

Embodiment 2

[0043]An embodiment of the present invention provides a control method for an intelligent industrial automatic control instrument system, comprising the following steps:

[0044] Step 1. The user now sets the distance between two adjacent power rollers 2 according to the usage requirements, and then conducts preliminary operation and debugging;

[0045] Step 2: Place the product on the power roller 2, and then the power roller 2 rotates to drive the product to move, and is transported from the previous power roller 2 to the next power roller 2, and the pressure detection ring 204 detects that the latter power roller 2 first contacts the product Stress points;

[0046] Step 3, reflect whether the distance between two adjacent power rollers 2 meets the transportation requirements of the product according to the force point;

[0047] Step 4: Control the extension of the pneumatic telescopic part 104 to make the sliding block 301 in a slidable state, control the rotation of the a...

Embodiment 3

[0049] refer to Figure 5 An embodiment of the present invention provides a control method for an intelligent industrial automatic control instrument system further comprising:

[0050] Determine the position of point A, which is the position of the highest point of the power roller 2;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com