Concrete embedded crack monitoring sensor and monitoring method

A technology for monitoring sensors and concrete, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of large errors in manual inspection methods, high detection time costs, and no way to repair, etc., to increase transmission paths and improve monitoring effect, the effect of increasing coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

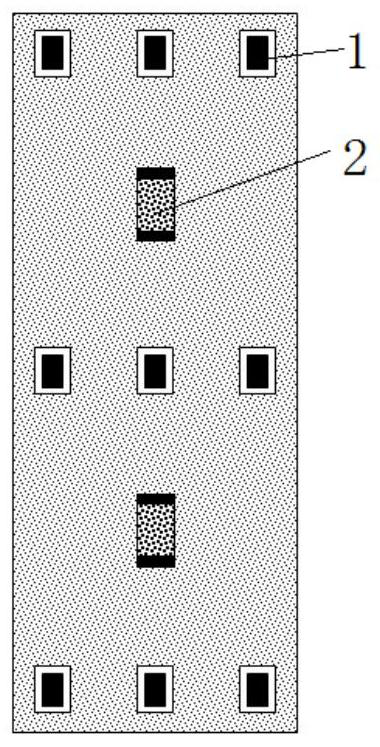

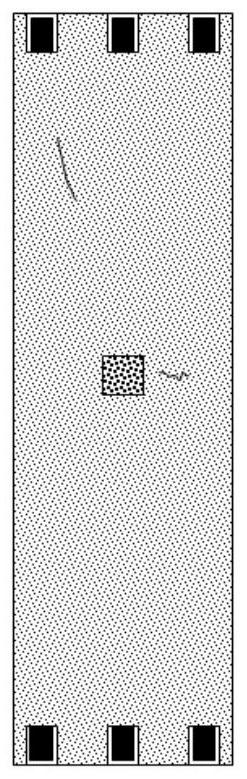

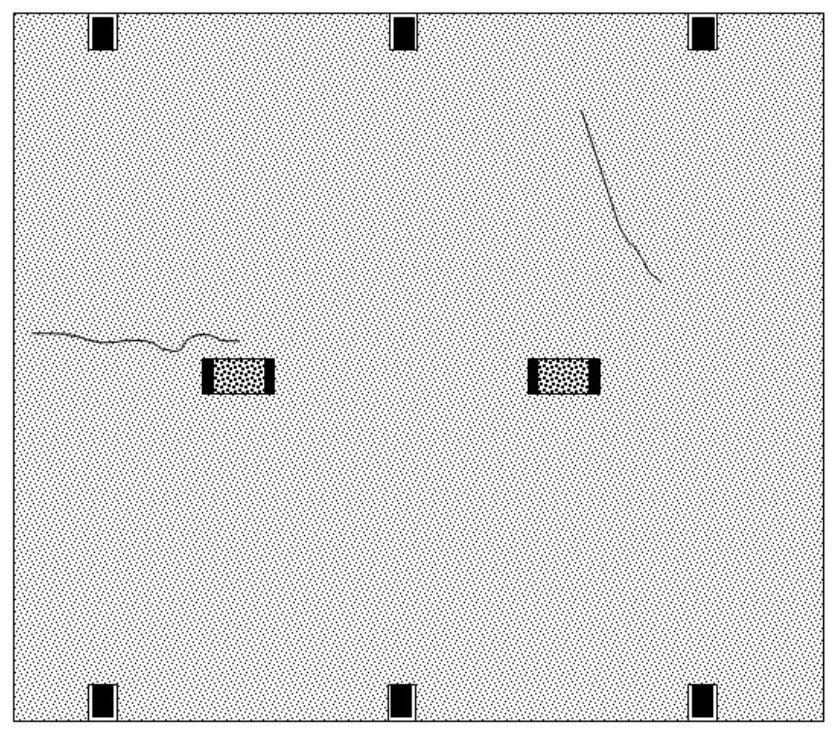

[0041] Such as Figure 1-3 As shown, a concrete embedded crack monitoring sensor system includes an array of ultrasonic probes, an embedded standard block 2, a vibration sensor, an analysis host and a power supply module;

[0042]On the upper and lower surfaces of the concrete to be monitored, installation holes for installing the ultrasonic probe array are respectively set. The number of installation holes is 9 on the upper surface of the concrete to be monitored and 9 on the lower surface, all arranged in a 3×3 array; 4 are set near the four corners of the top or bottom of the concrete, 4 are set near the midpoint of the edge of the top or bottom, and 1 is set at the center of the top or bottom;

[0043] The installation hole is used to install the ultrasonic probe 1, the ultrasonic probe 1 is a transceiving probe, which can both emit ultrasonic waves and collect ultrasonic waves, and the ultrasonic probe 1 is connected to the analysis host;

[0044] Embed the embedded stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com