Light source module of welding-free COB packaging structure

A light source module and packaging structure technology, which is applied in the direction of printed circuits, printed circuits, and electric solid devices connected to non-printed electrical components, can solve problems such as bonding wire misalignment, short-circuit connection, and packaging failure, which is not easy to achieve The effect of encapsulation failure, not easy to overflow, not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

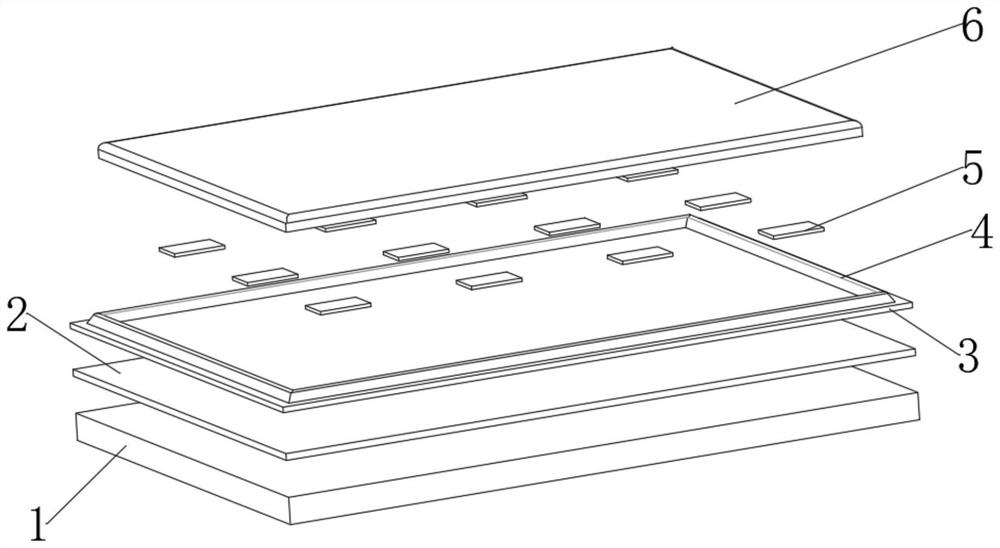

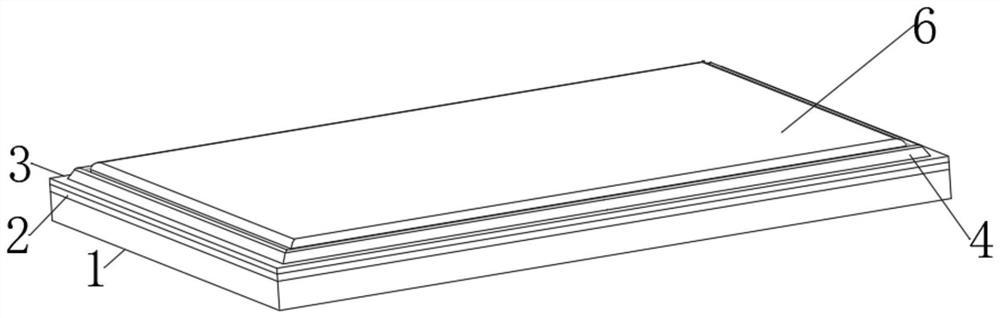

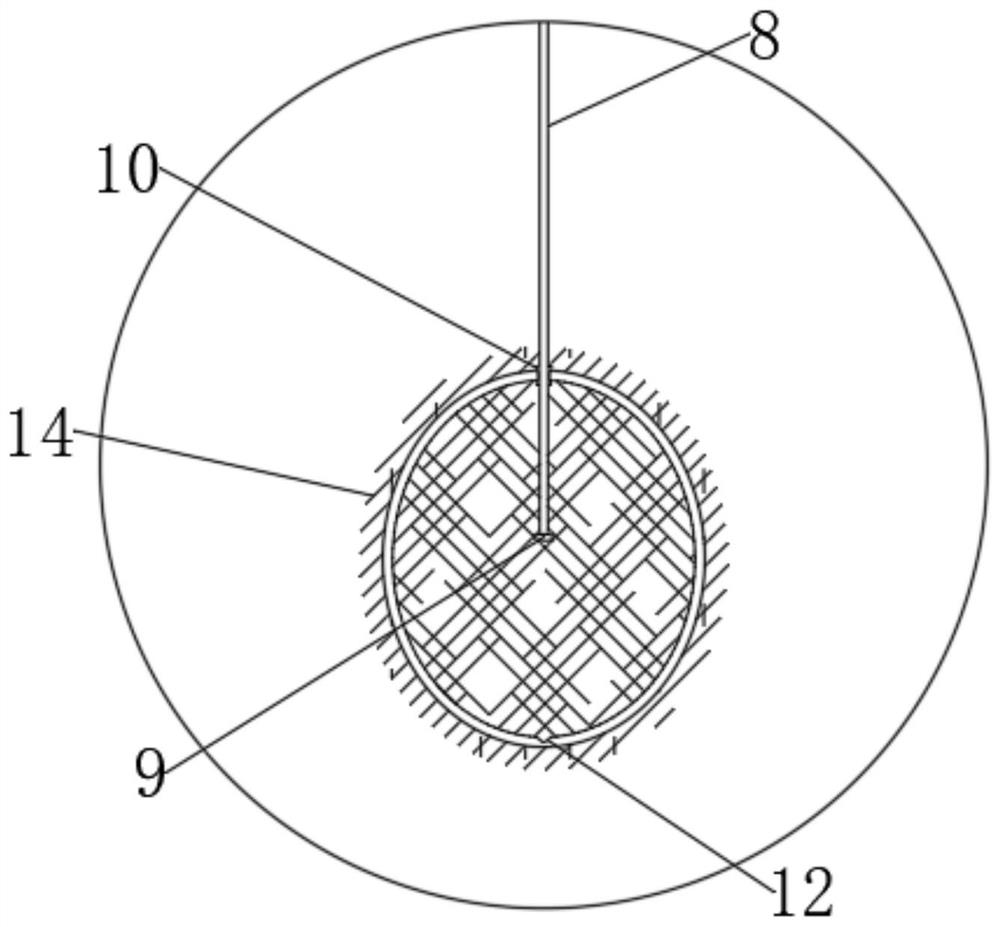

[0038] see Figure 1-5, a light source module with a solder-free COB packaging structure, comprising a metal substrate 1, an insulating layer 2 is fixedly connected to the upper end of the metal substrate 1, a circuit board 3 is fixedly connected to the upper end of the insulating layer 2, and a circuit board 3 is fixedly connected to an upper end of the circuit board 3. The glue dam 4 and a plurality of light source modules 5, the plurality of light source modules 5 are located inside the glue dam 4, the glue dam 4 is filled with encapsulation glue 6, the encapsulation glue 6 covers a plurality of light source modules 5, and the plurality of light source modules 5 is fixedly connected with a bonding wire 8, and the end of the bonding wire 8 away from the light source module 5 is covered with a storage spherical shell 11, and the end of the bonding wire 8 away from the light source module 5 runs through the storage spherical shell 11 and extends to the storage ball In the shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com