Ceramic atomization core and preparation method thereof

A technology of atomizing core and ceramics, which is applied in the field of atomizers, can solve the problems of limited application range, easy oxidation of stainless steel tubes, and high thermal conductivity, etc., and achieves a simple and efficient preparation method, which is conducive to industrial production and convenient operation and control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

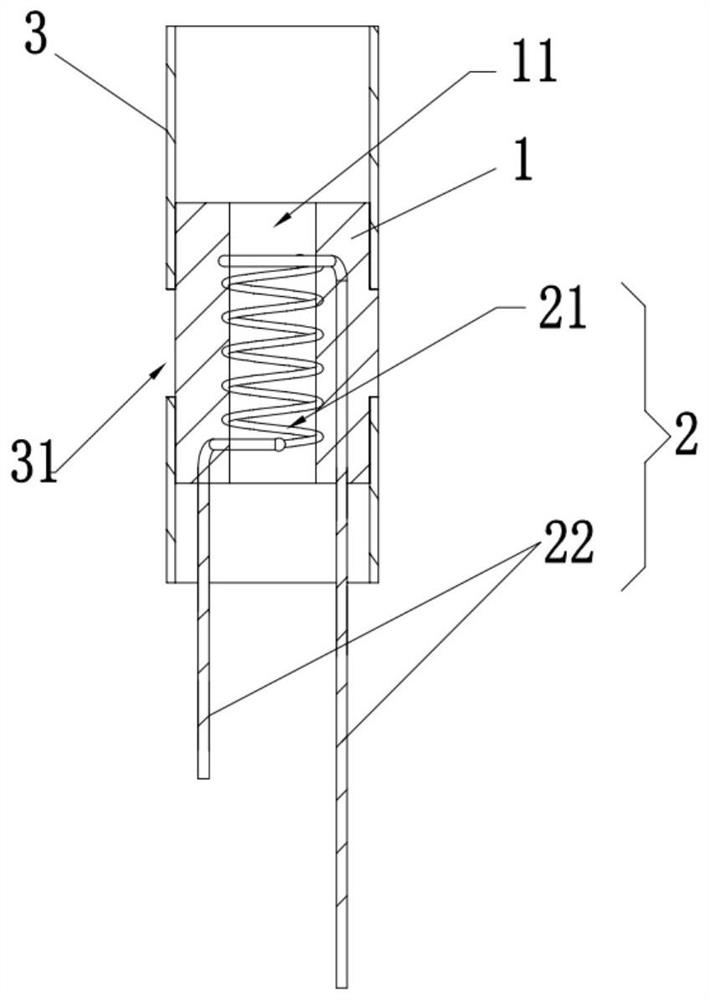

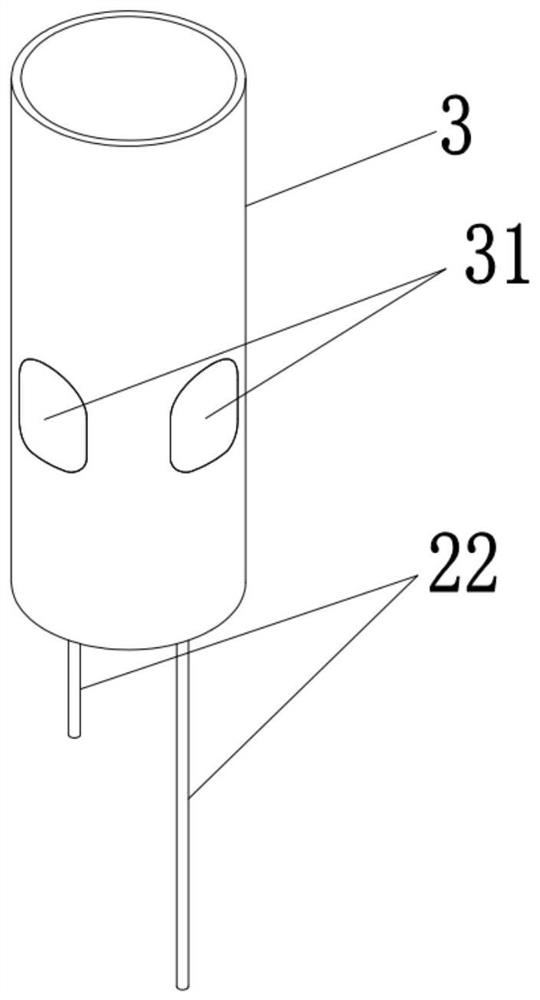

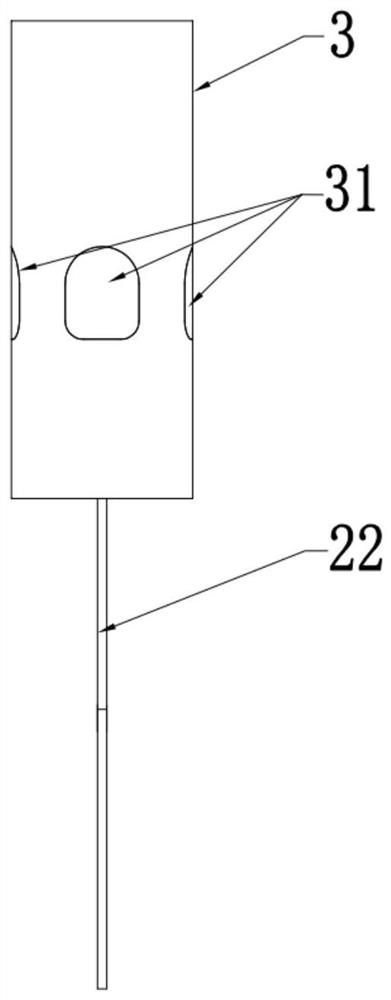

[0042] A ceramic atomizing core, a porous ceramic substrate 1, a heating component 2 and a stainless steel tube 3, the interior of the porous ceramic substrate 1 is provided with an air flow channel 11, and the air flow channel 11 runs through the upper surface and the lower surface of the porous ceramic substrate The side wall of the stainless steel tube 3 is provided with a plurality of oil inlet holes 31, the stainless steel tube 3 is sleeved on the outer wall of the porous ceramic substrate 1, the heating element 2 is embedded in the porous ceramic substrate 1 and Around the circumferential direction of the air flow channel 11, the end of the heating component 2 is provided with a heating wire extension 22, and the heating wire extension 22 protrudes out of the porous ceramic substrate 1, and the porous ceramic substrate 1 is composed of a porous It is made by sintering ceramic materials; the shell of the stainless steel tube 3 is silvery white, and the material of the stai...

Embodiment 2

[0063] A ceramic atomizing core, a porous ceramic substrate 1, a heating component 2 and a stainless steel tube 3, the interior of the porous ceramic substrate 1 is provided with an air flow channel 11, and the air flow channel 11 runs through the upper surface and the lower surface of the porous ceramic substrate The side wall of the stainless steel tube 3 is provided with a plurality of oil inlet holes 31, the stainless steel tube 3 is sleeved on the outer wall of the porous ceramic substrate 1, the heating element 2 is embedded in the porous ceramic substrate 1 and Around the circumferential direction of the air flow channel 11, the end of the heating component 2 is provided with a heating wire extension 22, and the heating wire extension 22 protrudes out of the porous ceramic substrate 1, and the porous ceramic substrate 1 is composed of a porous It is made by sintering ceramic materials; the shell of the stainless steel tube 3 is silvery white, and the material of the stai...

Embodiment 3

[0084] A ceramic atomizing core, a porous ceramic substrate 1, a heating component 2 and a stainless steel tube 3, the interior of the porous ceramic substrate 1 is provided with an air flow channel 11, and the air flow channel 11 runs through the upper surface and the lower surface of the porous ceramic substrate The side wall of the stainless steel tube 3 is provided with a plurality of oil inlet holes 31, the stainless steel tube 3 is sleeved on the outer wall of the porous ceramic substrate 1, the heating element 2 is embedded in the porous ceramic substrate 1 and Around the circumferential direction of the air flow channel 11, the end of the heating component 2 is provided with a heating wire extension 22, and the heating wire extension 22 protrudes out of the porous ceramic substrate 1, and the porous ceramic substrate 1 is composed of a porous It is made by sintering ceramic materials; the shell of the stainless steel tube 3 is silvery white, and the material of the stai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap