Detachable chair leg and assembling method thereof

A chair foot and foot piece technology, applied in the field of detachable chair feet and their assembly, can solve the problems of inconvenient assembly and disassembly operations, high transportation and storage costs, low tool efficiency, etc., so as to save transportation and storage costs and ensure accurate performance and improve assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

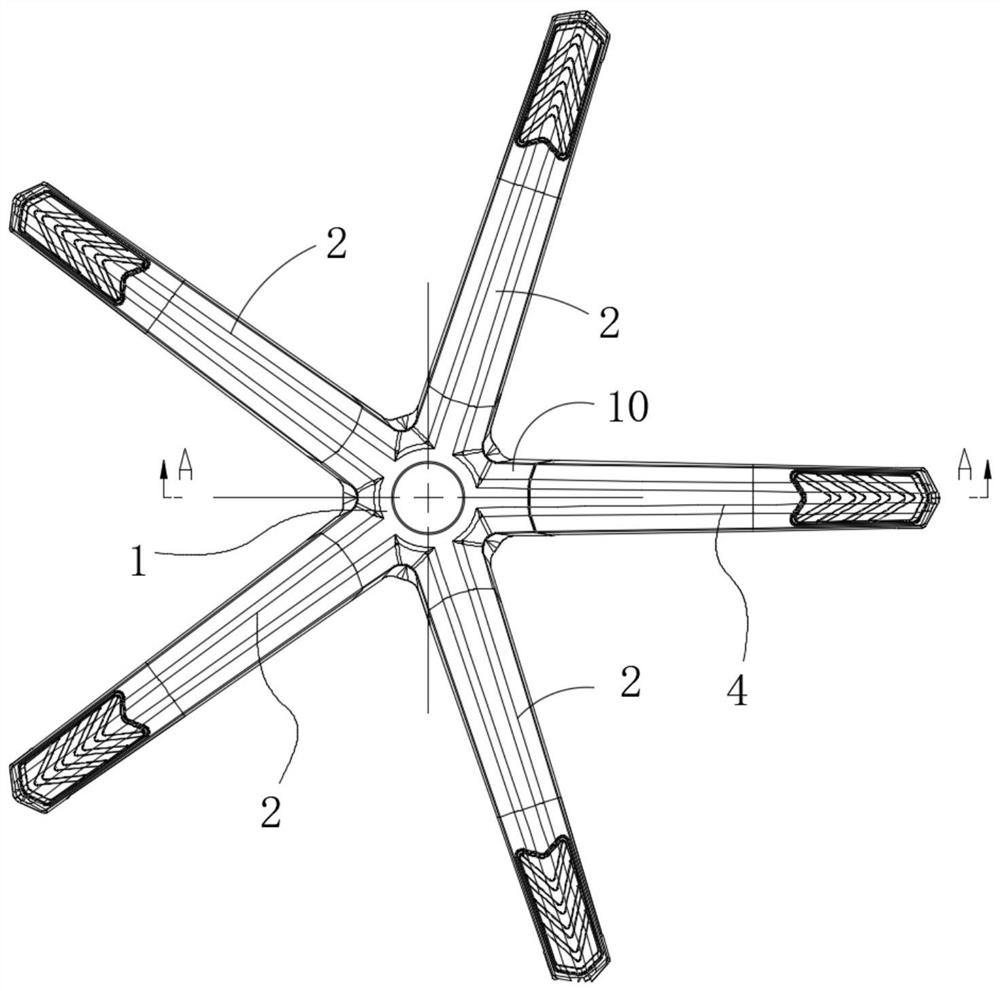

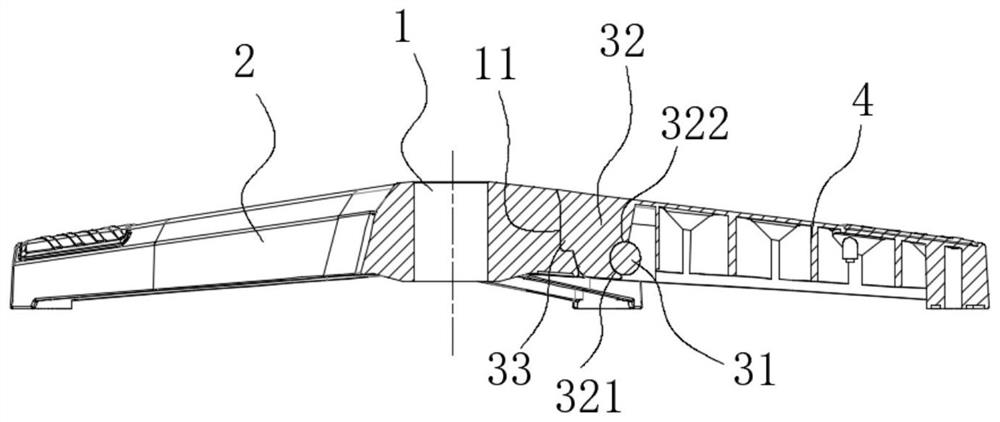

[0043] Such as figure 1 As shown, the detachable chair foot includes several integral foot pieces 2 integrally injection-molded with the center base 1, and a detachable foot piece 4 connected with the center base 1 through a rotating assembly connection mechanism 3, as Figure 5 As shown, the transverse section of the detachable foot piece 4 is U-shaped, and in order to improve the structural strength, a reinforcing rib 43 is provided in the U-shaped groove of the detachable foot piece 4 .

[0044] There are four integrated foot pieces 2, and the detachable foot pieces 4 and the integrated foot pieces 2 are evenly distributed around the circumference for supporting purposes.

[0045] The center of the center seat 1 is provided with a vertical shaft hole to facilitate the assembly of the seat cushion shaft.

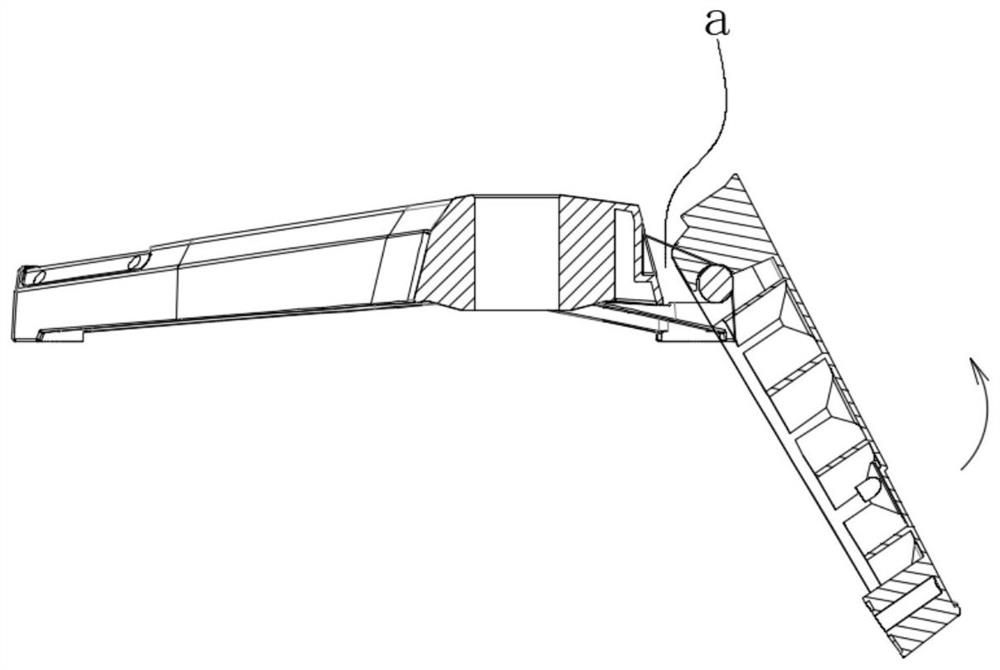

[0046] Such as Figure 2-Figure 7 As shown, the described rotary assembly connection mechanism 3 includes:

[0047] The radial support arm 30 is connected with the cent...

Embodiment 2

[0081] Such as figure 1 and Figure 9 As shown, a wheeled chair foot has the detachable chair foot described in Embodiment 1, and a roller 5 installed on the lower side of the outer end of the integral leg 2 and the detachable leg 4 .

Embodiment 3

[0083] A swivel chair has the roller chair foot described in the second embodiment, and a seat cushion assembly and a backrest assembly installed on the roller chair foot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com