Brake caliper integrated with brake booster

A brake booster and brake caliper technology, which is applied in the direction of brakes, brake transmissions, transportation and packaging, etc., can solve problems such as limited installation space, high installation cost, and increased cost of pedal feel simulators. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

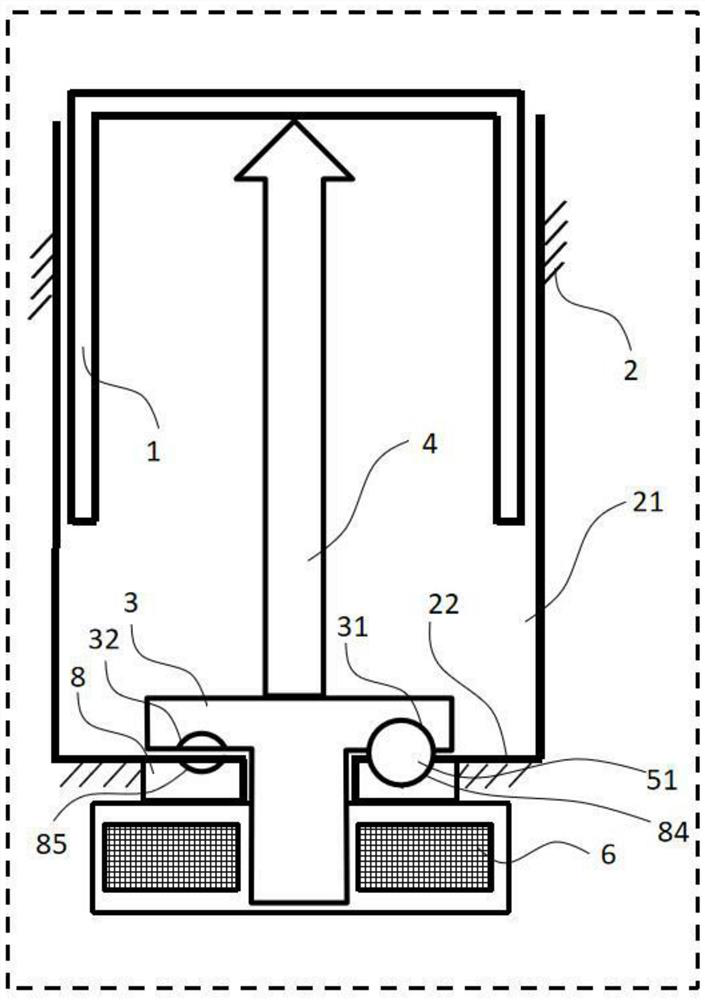

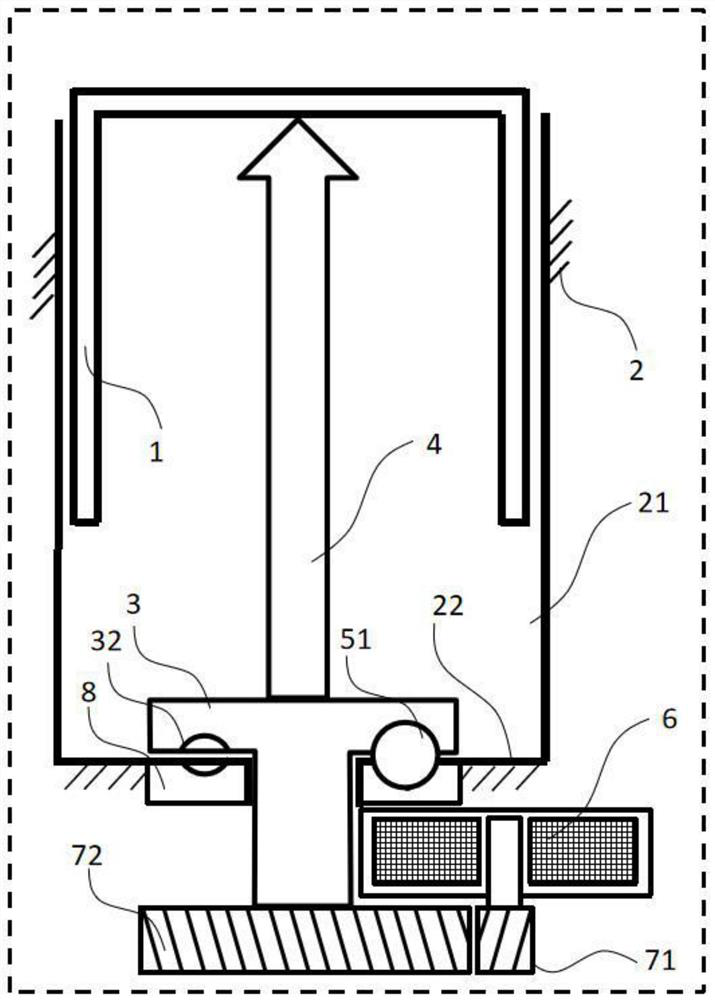

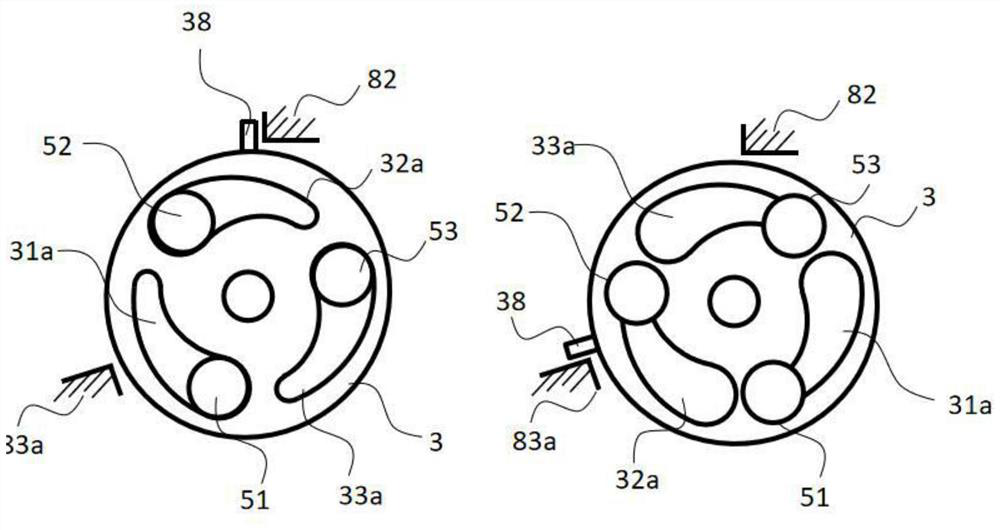

[0043] Such as figure 1 As shown, in the brake caliper, the caliper piston 1 is arranged in the brake cylinder 21 in the caliper body 2, and a single-cylinder, double-cylinder or even multi-cylinder pistons are integrated in the caliper for powering the caliper. This piston is generally called a wheel cylinder, and it can also be called a sub-cylinder. The ball ramp transmission mechanism is composed of a rotating member 3 provided with first arc surfaces 31, 32 and corresponding balls 51. A contact member 8 is fixed outside the clamp, and another second arc surface 84, 85 is formed inside the contact member 8. . The rotating member 3 is driven by a power source 6 to generate rotation, where the power source may be a motor or an element with a rotating bearing driven by a motor to rotate. When the rotating member 3 rotates, the rotation is converted into a linear motion of the rotating member through the mutual motion between the ball and the ramp, and this linear motion is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com