Interwell agitation type gas lift induced flow device and gas lift induced flow method

A technology of blowout induction and gas lift, which is applied to wellbore/well valve devices, earthwork drilling and production, wellbore/well components, etc. It can solve problems such as liquid accumulation and stop blowout in self-flowing wells, and achieve short operation period and high operation efficiency. The effect of low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

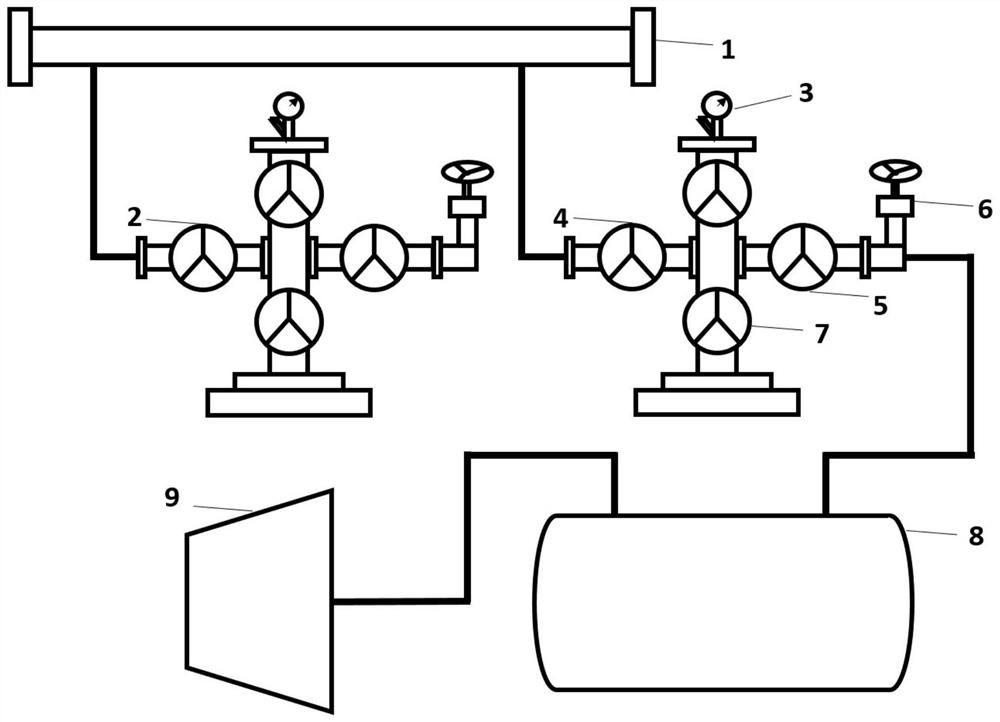

[0031] In order to better understand the purpose, structure and function of the present invention, an interwell agitation type gas lift induced blowout device and a gas lift induced blowout method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

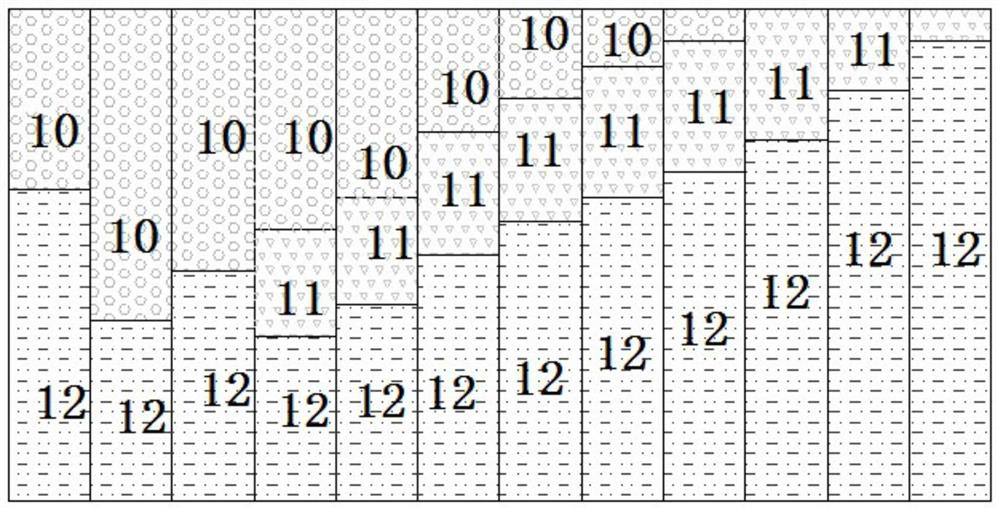

[0032] Such as Figure 1-Figure 2 As shown, the present invention includes: a kill manifold 1 arranged outside the wellbore, and a number control device connected to the kill manifold 1 (the number in this embodiment is two); wherein, the number control device in the number control device The first road: it is provided with: several well-side service oil pipe control valves 2 installed on the pipeline, the pipeline is cross-shaped, and each cross-shaped pipe has a well-side service oil pipe control valve 2; The well-side service oil pipe control valve 2 is also connected to the oil pressure gauge of the fault well through the pipeline; the well-side service oil pipe con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com