Turbine rotor device with reinforced cooling structure

A technology of turbine rotor and cooling structure, applied in the direction of blade support components, climate sustainability, engine components, etc. The service life of the small wheel and other issues can be achieved to reduce the temperature, reduce thermal stress, and reduce the effect of temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0033] refer to figure 1 — Figure 6 :

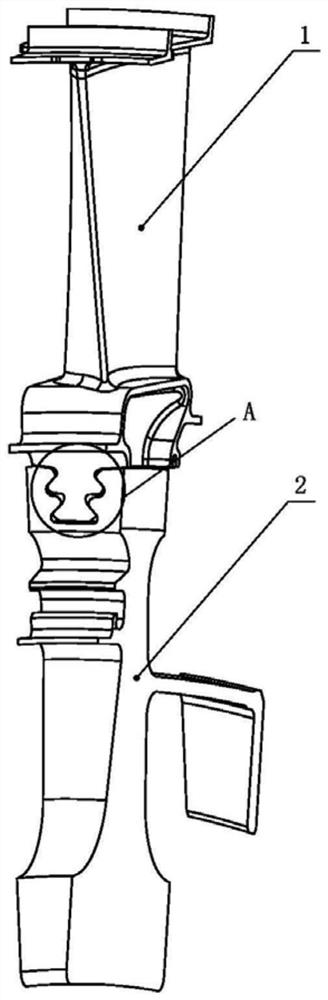

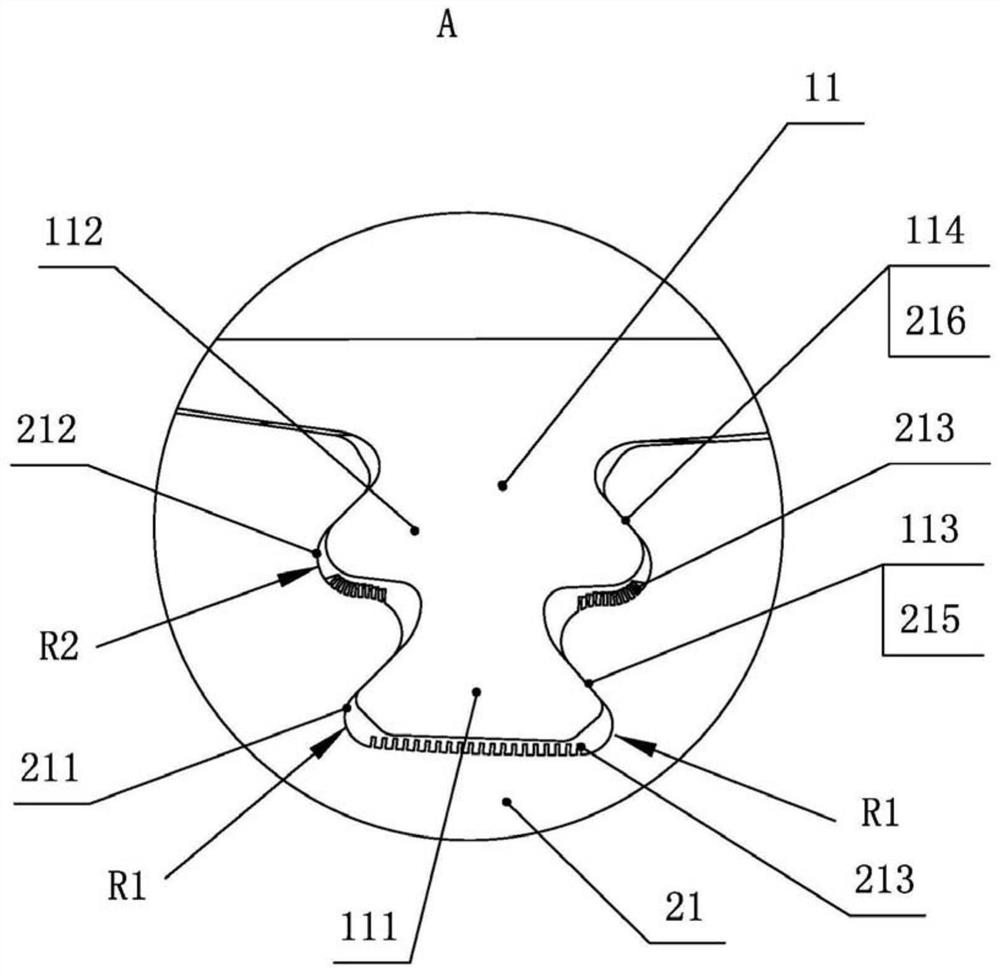

[0034] A turbine rotor device with a reinforced cooling structure, including a blade 1 and a disc 2 matched and connected by a fir tree-shaped tenon 110 and a tenon groove 21; the tenon 110 is provided with connected first tenons 111, second tenons tooth 112, the wheel disc 2 is provided with a first tenon groove 211 and a second tenon groove 212 respectively matched with the first tenon tooth 111 and the second tenon tooth 112, and the first tenon groove 211 is provided with a first The upper side wall 215 of the tenon groove is matched with the upper tooth surface 113 of the first tenon tooth. The upper tooth surface 114 is matched and fitted.

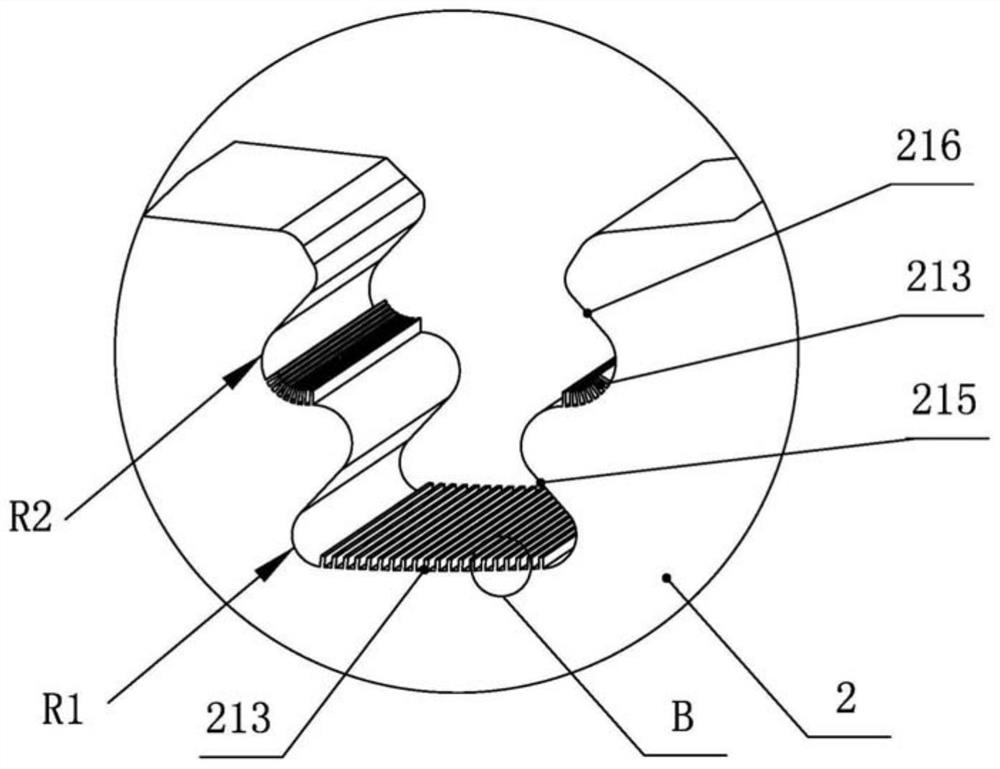

[0035] The mortise 21 is provided with large arcs whose radii are R1 and R2 respectively. The upper side walls 216 of the tenon and groove respectively form cavities with other tooth surfaces of the first tenon tooth and the second tenon tooth after they are attached to each other.

[003...

no. 2 example

[0045] refer to Figure 1-Figure 4 : A turbine rotor device with a reinforced cooling structure, including a blade 1 and a disc 2 that are matched and connected by a fir tree-shaped tenon 110 and a tenon groove 21; Tenon teeth 112, the wheel disc 2 is provided with a first tenon groove 211 and a second tenon groove 212 respectively matched with the first tenon teeth 111 and the second tenon teeth 112, and the first tenon groove 211 is provided with a first tenon groove 212 The upper side wall 215 of a mortise is matched with the upper tooth surface 113 of the first mortise, and the upper side wall 216 of the second mortise of the second mortise 212 is matched with the second mortise of the second mortise 112. The upper tooth surfaces 114 of the teeth are fitted together.

[0046] The mortise 21 is provided with large arcs whose radii are R1 and R2 respectively. The upper side walls 216 of the tenon and groove respectively form cavities with other tooth surfaces of the first ...

no. 3 example

[0054] refer to figure 1 , figure 2 , Figure 5 , Figure 6 :

[0055] A turbine rotor device with a reinforced cooling structure, including a blade 1 and a disc 2 matched and connected by a fir tree-shaped tenon 110 and a tenon groove 21; the tenon 110 is provided with connected first tenons 111, second tenons tooth 112, the wheel disc 2 is provided with a first tenon groove 211 and a second tenon groove 212 respectively matched with the first tenon tooth 111 and the second tenon tooth 112, and the first tenon groove 211 is provided with a first The upper side wall 215 of the tenon groove is matched with the upper tooth surface 113 of the first tenon tooth. The upper tooth surface 114 is matched and fitted.

[0056] The mortise 21 is provided with large arcs whose radii are R1 and R2 respectively. The upper side walls 216 of the tenon and groove respectively form cavities with other tooth surfaces of the first tenon tooth and the second tenon tooth after they are attac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com