Tooth profile of pin gear in pin gear transmission

A pin-tooth transmission and pin-gear technology, which is applied in the field of pin gear tooth profile design, can solve the problems affecting the stability, service life and bearing capacity of pin-tooth transmission, reduction of pin-tooth transmission transmission efficiency, and inaccurate contact strength checking, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

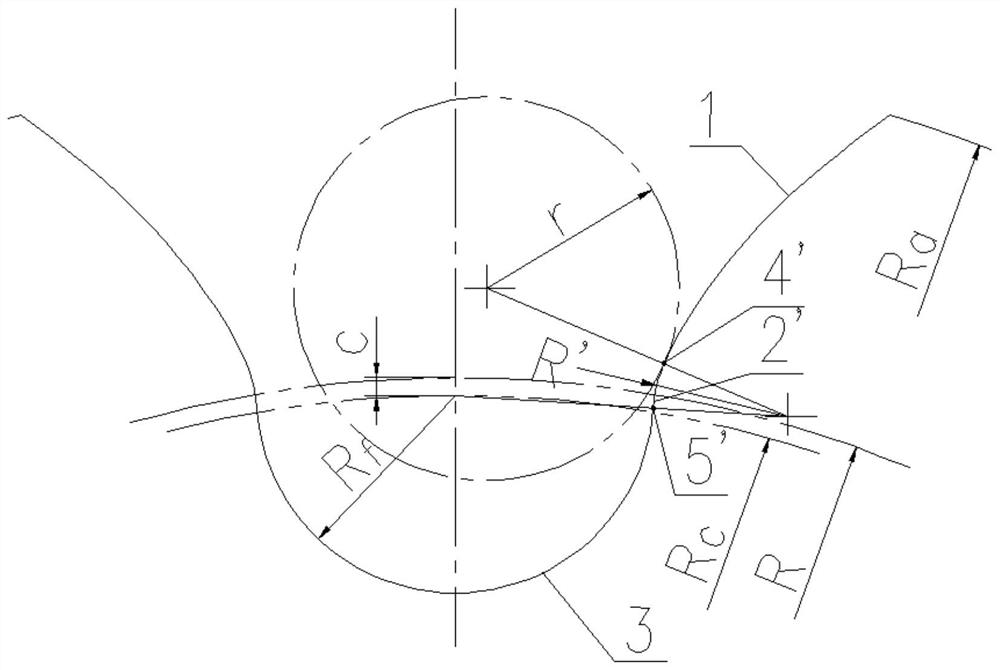

[0012] The tooth profile of the pin gear of prior art is as figure 1 As shown, there are three types of pin-tooth transmission: external, internal and rack. Open line; the tooth profile of the pin gear is composed of the tooth top above the pitch circle and the dedendum below the pitch circle. The tooth top part is composed of the conjugate tooth profile curve 1 near the pitch circle and the pitch A part of the circle and above the tooth profile transition arc 2′ is composed of two smooth connecting curves, the tooth profile curve of the tooth top part is the meshing working part, and the tooth root part is composed of the pitch circle and the tooth profile transition arc 2 ′ and a part of the dedendum arc R f 3. It consists of two smooth connecting curves; the tooth profile transition arc 2′ is connected with the conjugate tooth profile curve 1 and the dedendum arc R f 3 is inscribed at the tangent point 4' and circumscribed at the tangent point 5', and the tangent point 4'...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com