Machine tool main shaft temperature rise test device

A temperature rise test, machine tool spindle technology, used in mechanical bearing testing, measuring devices, testing of mechanical components, etc., can solve the problems of low accuracy, shortening, and large human error of measurement data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

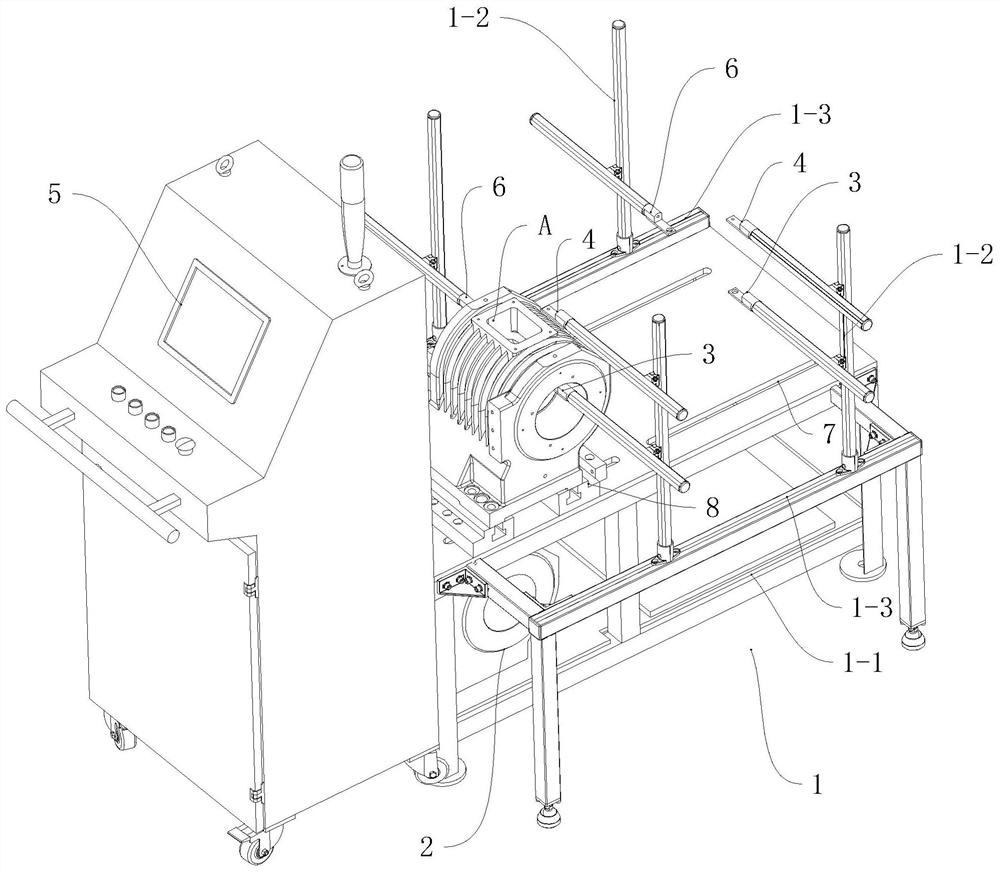

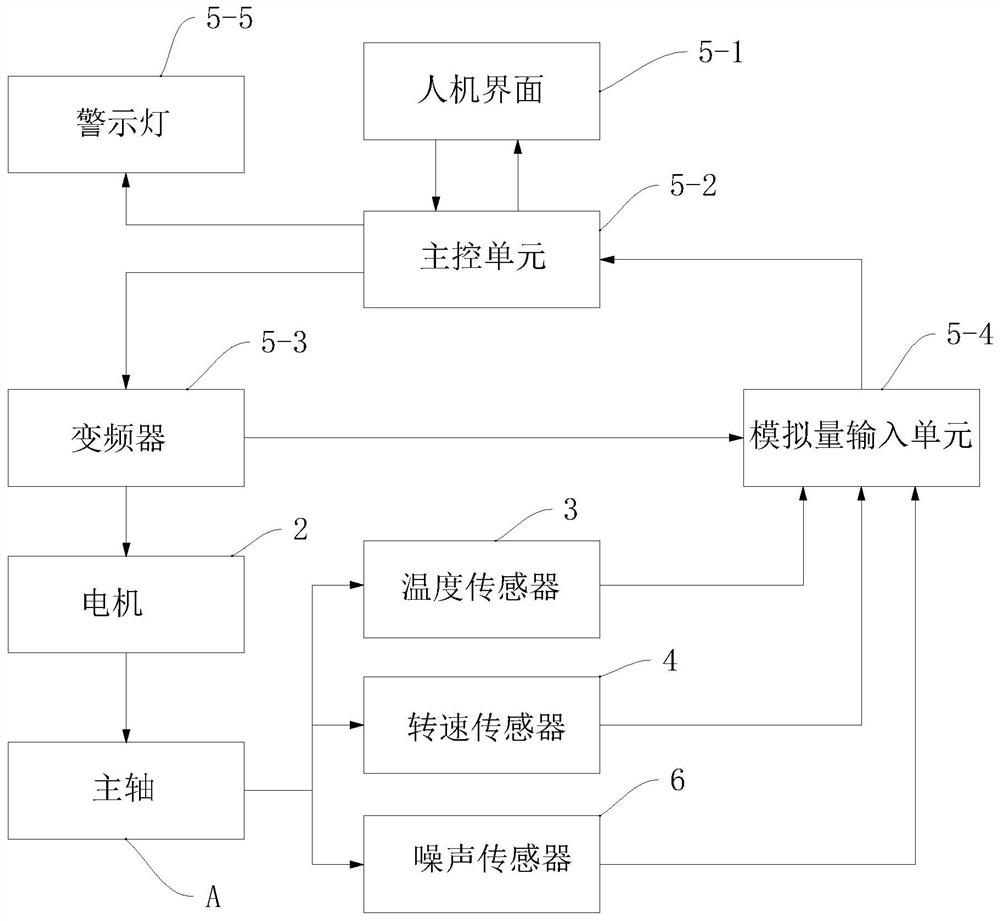

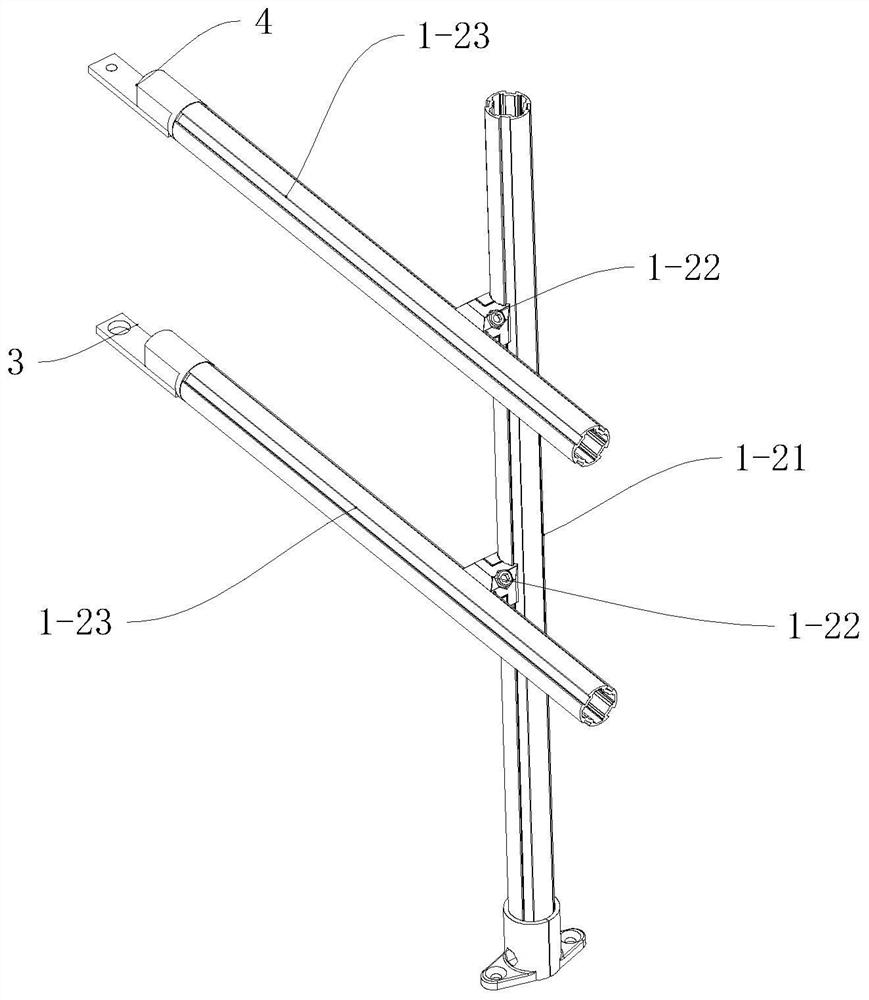

[0019] The technical scheme of the present invention will be further described below in conjunction with the specific embodiment that accompanying drawing provides, as figure 1 The shown test device includes a mounting frame 1 and a main control platform 5. The mounting frame 1 is used to fix the main shaft. A motor 2 is arranged on the mounting frame 1 to drive the rotation of the main shaft for testing. A temperature sensor is also provided on the mounting frame 1. 3 and speed sensor 4 are used to detect temperature and speed changes, wherein at least two temperature sensors 3 are provided, one is used to detect the ambient temperature, and the other is used to detect the temperature of the main shaft A (the number of spindle temperature detection is set according to the number of bearings on the main shaft , since the heating parts of the main shaft are mainly concentrated in the bearing installation position, the temperature sensor is also set accordingly according to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com