Battery cell preparation method, battery cell and battery

A technology of cells and electrode sheets, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as short circuit of cells, affecting cell performance, safety, and escape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

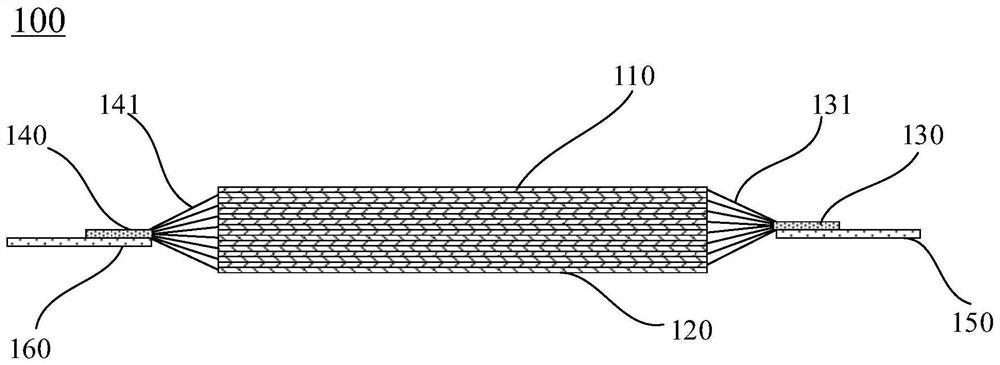

[0023] According to an embodiment of the present invention, a method for preparing a soft-packed battery cell includes the following steps:

[0024] A plurality of electrode sheets are stacked, and the electrode sheets are independently connected with reserved sub-tabs, wherein the plurality of electrode sheets include a plurality of positive electrode sheets and a plurality of negative electrode sheets that are alternately stacked;

[0025] The reserved sub-tabs connected to the electrode sheets of the same electrical polarity are stacked and arranged, and the adjacent reserved sub-tabs are bonded with conductive glue to prepare the reserved tabs;

[0026] Bond the external tab and reserved tab with conductive glue.

[0027] Wherein, the electrode sheet is a sheet-shaped electrode material formed after the electrode material is coated on the surface of the current collector. According to its discharge properties, it can be divided into positive electrode sheets and negative ...

Embodiment 1

[0062] (1) A plurality of electrode sheets are sequentially stacked to form an electrode body. Among them, the total number of positive pole pieces is 30, and the total number of negative pole pieces is 31. The positive pole pieces and the negative pole pieces are stacked alternately. The reserved sub-tab on the positive pole piece is located at the right end of the positive pole piece. The sub-tab is located at the left end of the negative plate.

[0063] (2) In the process of laying each positive electrode sheet and negative electrode sheet, the adhesive conductive paste is scraped on the exposed side of each reserved sub-tab correspondingly, and the glue is applied along the short side parallel to the reserved sub-tab. The edge area is coated with glue, the width of the glue is 3mm, and the length of the glue is 43mm of the short side length of the reserved sub-tab, by applying 0.5kgf / cm 2 Press the reserved sub-tab set later to the reserved sub-tab set earlier; repeat thi...

experiment example

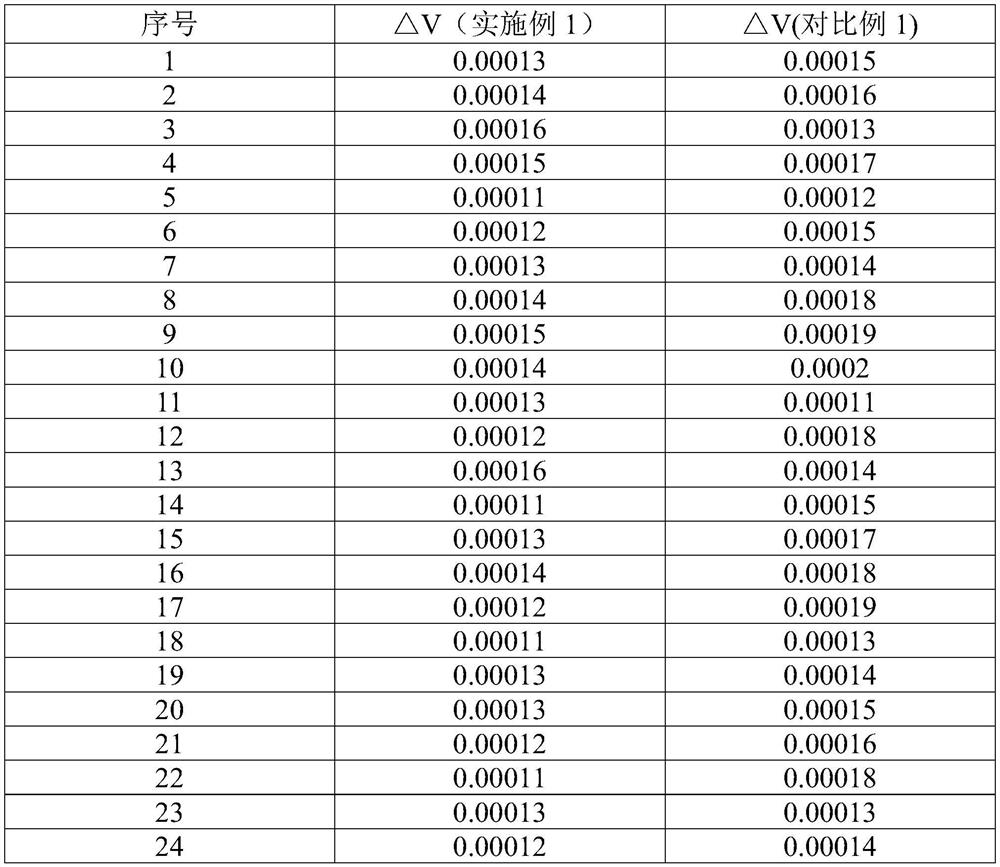

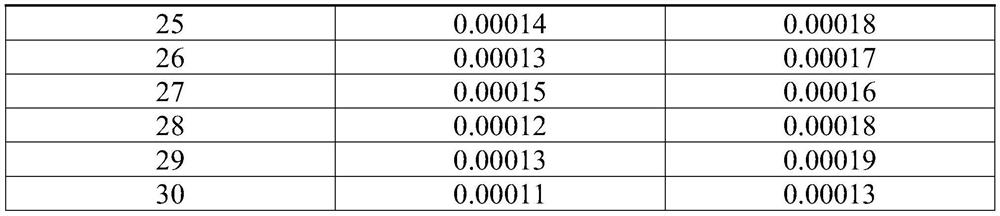

[0072] According to the preparation method as in Example 1, 30 battery samples were prepared, and at the same time, 30 battery samples were prepared according to the preparation method of Comparative Example 1, and the positive tabs or negative tabs were randomly checked, and all the battery samples were tested uniformly. The discharge level is expressed by its self-discharge rate ΔV, and the specific test results of ΔV can be seen in Table 1.

[0073] Table 1

[0074]

[0075]

[0076] Among them, the higher the ΔV, the higher the self-discharge rate.

[0077] As shown in Table 1, for Example 1, the measured maximum value of ΔV is 0.00016, the measured minimum value of ΔV is 0.00011, the difference between the maximum and minimum values is 0.00005, and the average value of ΔV is 0.00013. For Comparative Example 1, the measured maximum value of ΔV was 0.0002, the measured minimum value of ΔV was 0.00011, the difference between the maximum and minimum values was 0.00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com