Flame retardant power cable protection tube

A power cable and protection tube technology, applied in the field of flame retardant power cable protection tube, can solve the problems of low power cable protection strength, poor power cable stability, poor flame retardant performance, etc., to achieve enhanced protection effect, enhanced Stability, improve the effect of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

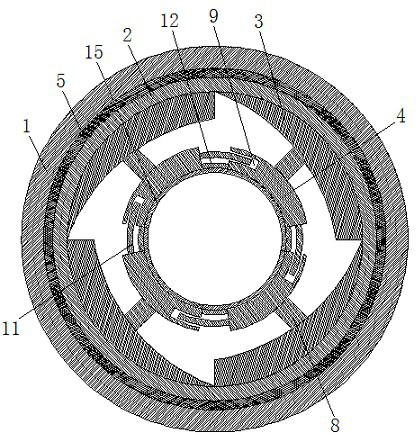

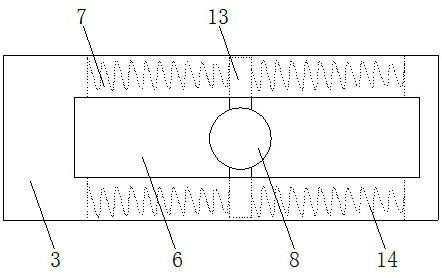

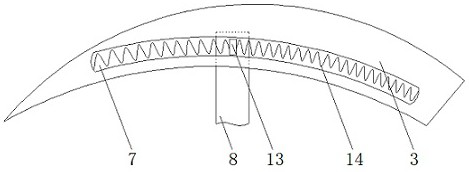

[0024] If attached Figure 1-7 As shown: a flame retardant power cable protection tube, including an external pipe body 1, an inner pipe body 2, a positioning block 3 and a fastening block 4, characterized in that: the inner pipe body 2 is placed in the outer pipe body 1, the inner pipe body 2 and the outer pipe body 1 are connected by thread, to facilitate the installation between the outer pipe body 1 and the inner pipe body 2, improve the assembly efficiency of the power cable protection tube, the positioning block 3 is provided in the inner pipe body 2, the positioning block 3 is provided with a positioning groove 6, and the limited position groove 7 is set on the positioning block 3, And the limit groove 7 and the positioning groove 6 is connected, the middle of the fastening block 4 is provided with a connecting rod 8, at one end of the fastening block 4 is provided with a card slot 9, a fixing slot 10, at the other end of the fastening block 4 is provided with a card post 11...

Embodiment 2

[0032] If attached Figure 8 As shown: a flame retardant power cable protection tube, including an external pipe body 1, an inner pipe body 2, a positioning block 3 and a fastening block 4, characterized in that: the inner pipe body 2 is placed in the outer pipe body 1, the inner pipe body 2 and the outer pipe body 1 are connected by thread, to facilitate the installation between the outer pipe body 1 and the inner pipe body 2, improve the assembly efficiency of the power cable protection tube, the positioning block 3 is provided in the inner pipe body 2, the positioning block 3 is provided with a positioning groove 6, and the limited position groove 7 is set on the positioning block 3, And the limit groove 7 and the positioning groove 6 is connected, the middle of the fastening block 4 is provided with a connecting rod 8, at one end of the fastening block 4 is provided with a card slot 9, a fixing slot 10, at the other end of the fastening block 4 is provided with a card post 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com