Preparation method of whole-bean soy sauce

A technology of soy sauce and soybeans, which is applied in the field of soy sauce, and can solve the problems of easy-to-contaminate koji, high cost of raw materials, and high moisture content in the production of koji

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

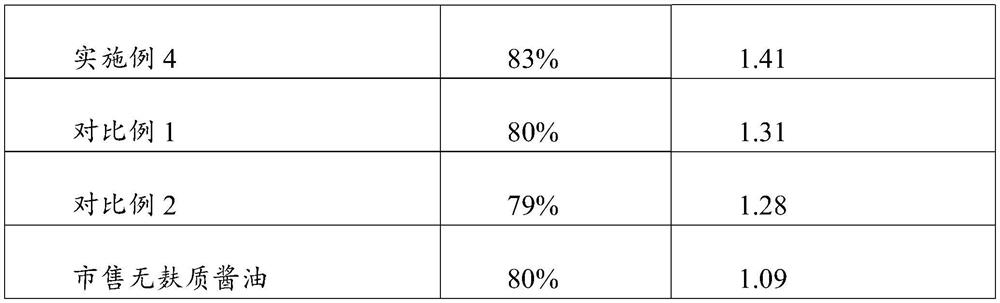

Examples

Embodiment 1

[0033] A kind of embodiment of the preparation method of whole bean soy sauce of the present invention, the method described in the present embodiment comprises the following steps:

[0034] (1) Raw material pretreatment: the soybeans after screening and removing impurities are divided into soybean A60% and soybean B40% according to weight percentage, and soybean A is crushed, and the particle size of soybean A after crushing is ≥6. 40% of the total weight; the soybean B is ground, and the particle size of the soybean B after grinding can pass through a 16-mesh sieve;

[0035] (2) Moisturizing: adding 35°C water to the crushed soybeans A to moisten the water, the increased weight after the moistening is 50% of the weight of the crushed soybeans A, and the water after the moistening is obtained. soybean A;

[0036] (3) Cooking: steam the moistened soybean A to make it mature, the cooking pressure is 0.20 MPa, and the cooking time is 5 minutes to obtain the mature soybean A;

...

Embodiment 2

[0042] A kind of embodiment of the preparation method of whole bean soy sauce of the present invention, the method described in the present embodiment comprises the following steps:

[0043] (1) Raw material pretreatment: divide the soybeans after screening and removing impurities into soybeans A80% and soybeans B20% by weight percentage, and soybeans A are crushed. 30% of the total weight; the soybean B is ground, and the particle size of the soybean B after grinding can pass through a 16-mesh sieve;

[0044] (2) Moisturizing: adding 35°C water to the crushed soybeans A to moisten the water, the increased weight after the moistening is 50% of the weight of the crushed soybeans A, and the water after the moistening is obtained. soybean A;

[0045] (3) Cooking: steam the moistened soybean A to make it mature, the cooking pressure is 0.22 MPa, and the cooking time is 3 minutes to obtain the mature soybean A;

[0046] (4) heat treatment: puffing the milled soybean B to make it ...

Embodiment 3

[0051]A kind of embodiment of the preparation method of whole bean soy sauce of the present invention, the method described in the present embodiment comprises the following steps:

[0052] (1) Raw material pretreatment: the soybeans after screening and removing impurities are divided into soybean A 50% and soybean B 50% according to weight percentage, and soybean A is crushed. 80% of the total weight of A; grind soybean B, and the particle size of soybean B after grinding can pass through a 16-mesh sieve;

[0053] (2) Moisturizing: adding 35°C water to the crushed soybeans A to moisten the water, the increased weight after the moistening is 40% of the weight of the crushed soybeans A, so that the water after the moistening is obtained. soybean A;

[0054] (3) Cooking: Cook the moistened soybean A to make it mature, the cooking pressure is 0.15MPa, and the cooking time is 10min, to obtain the mature soybean A;

[0055] (4) heat treatment: puffing the milled soybean B to make...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com