Wool system and method

A hair feeding and brushing technology, which is applied in the field of twisting system, can solve the problems of uneven bristles of pipeline brushes, poor quality and low density of pipeline brushes, and achieves the effect of improving twisting effect, uniform brushing and eliminating accumulated errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

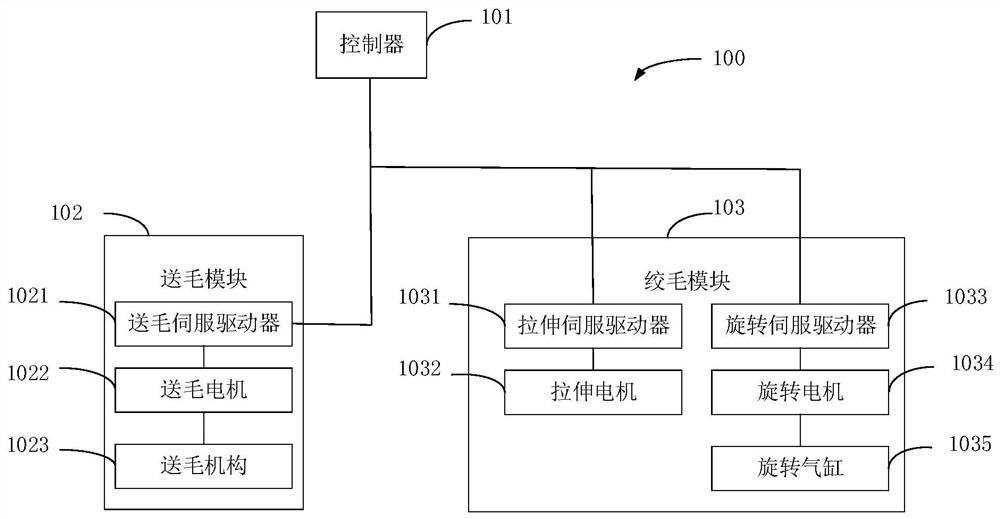

[0049] Referring to FIG. 1, an embodiment of the present disclosure provides a stranding system.

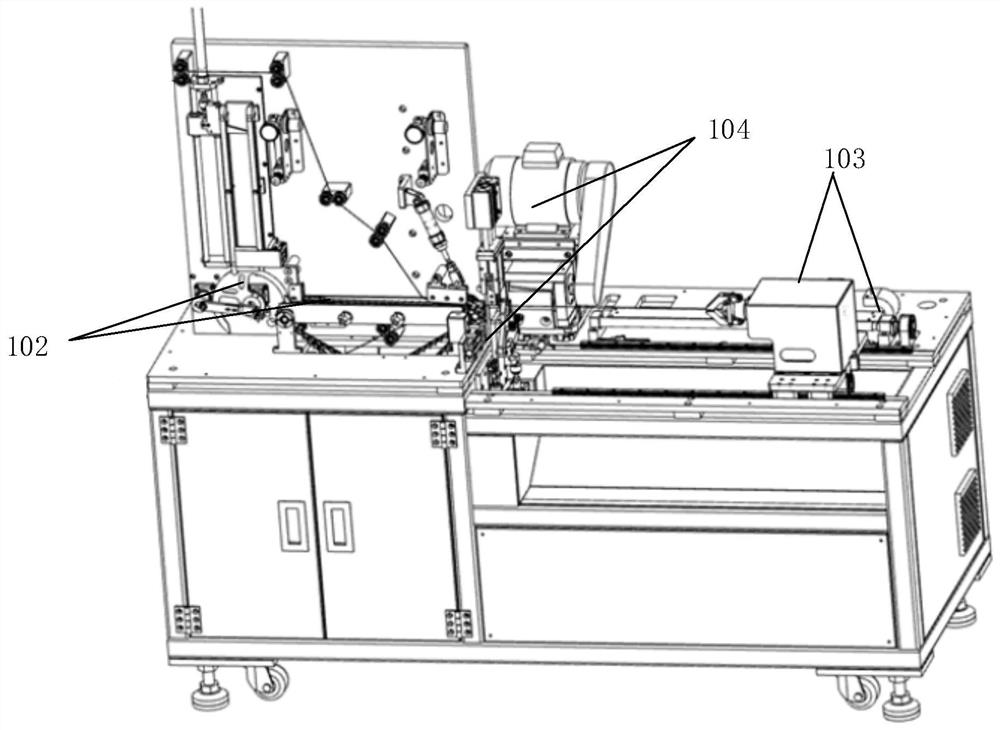

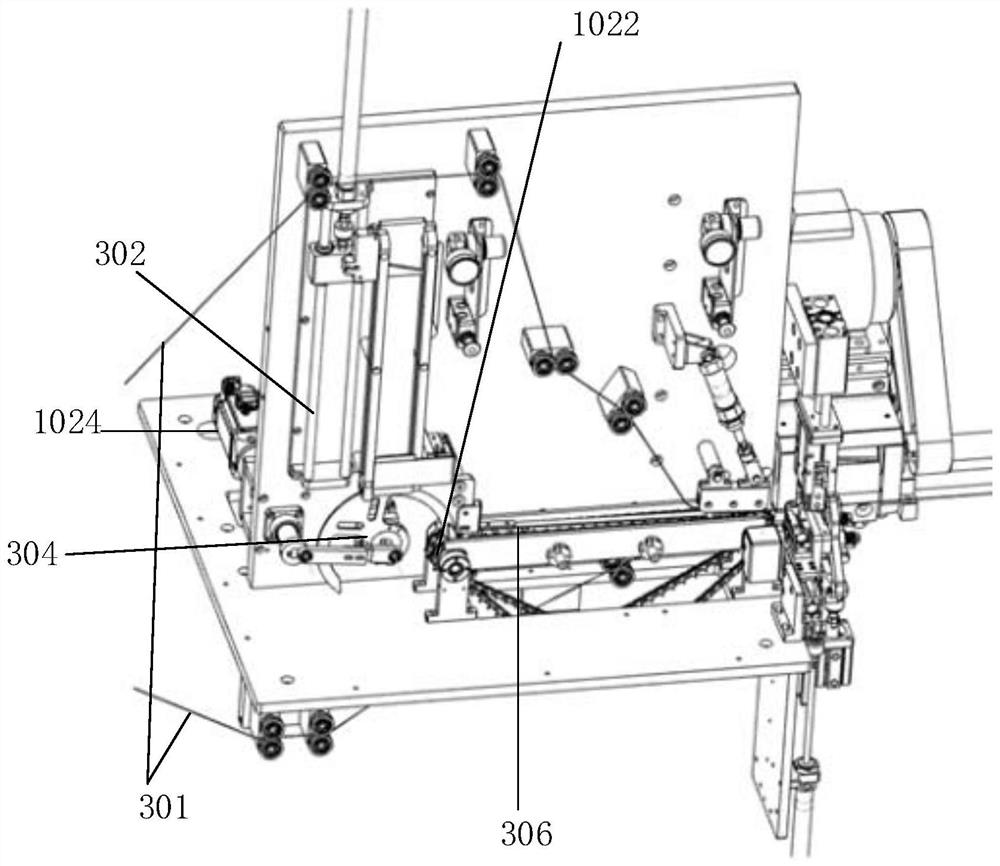

[0056] Please refer to FIG. 2 , the frame main body is provided with a hair feeding module 102, a twisting module 103 and a material cutting module 104. see

[0061] In this embodiment, the controller 101 is also used to control the

[0070] The position sensor 1026 is used to enter the position at the positioning protrusion of the hair feeding mechanism 1023

[0073] In this embodiment, the position sensor 1026 may be a photoelectric sensor. Photoelectric sensor is integrated for sending and receiving

[0075] The position sensor 1026 is used to generate the sensing when the sprocket protrusion enters the sensing area

[0079] It is further added that, the stranding system 100 also includes a touch screen electrically connected to the controller 101, so the

Embodiment 2

[0082] In addition, the embodiment of the present disclosure provides a method for stroking, which is applied to the skeining system provided in Embodiment 1.

[0090] setting the rotational speed and the stretching speed according to a second matching ratio; and / or,

[0091] The drawing speed and the hair feeding speed are set according to the first matching ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com